Features of sulphate-resistant cement

There is an opinion that reinforced concrete products are the most durable and durable. However, this wording is a delusion. Under inappropriate operating conditions, concrete structures are also subject to serious deformations and damage. They are adversely affected by severe frosts, subsidence of soil layers, oxygen oxidation, precipitation and the effects of various chemicals.

The best option for construction is sulfate-resistant cement. This building material has received the greatest popularity in those regions where weather conditions leave much to be desired. This applies to the territories for which the characteristic features are sudden temperature changes and a large amount of precipitation.

What it is?

Sulfate-resistant cement or Portland cement is a special building material that differs from the usual analog and is resistant to the negative effects of chemical compounds and the changing whims of nature. The main scope of Portland cement includes the construction of pumping stations, water discharge and water outlet structures. Concrete and piles of zinc sulphate building material are used to build most industrial structures.

Sulfate-resistant cement hardens rather slowly, but in the hardened state it has a very high density. The last factor is its main advantage among other building materials.

Kinds

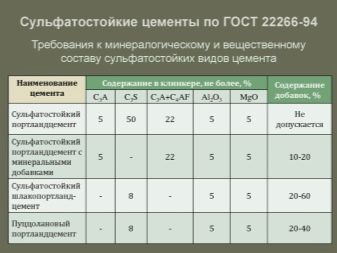

By its composition, sulfate-resistant cement is divided into the following types:

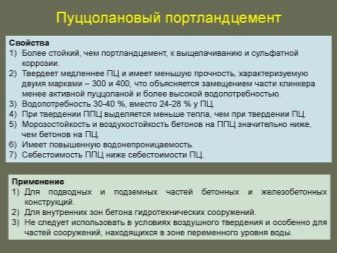

- pozzolanic portland cement;

- sulphate-resistant slag Portland cement;

- sulphate-resistant portland cement;

- sulphate-resistant portland cement with the addition of minerals.

Now let's take a quick look at each of these building materials:

- Pozzolanic Portland cement contains a mixture of granulated blast furnace slag and pozzolanas.Under the latter refers to products of volcanic origin in the form of ash, tuff and pumice. Pozzolans are active mineral additives in the manufacture of Portland cement. This building material is relatively poorly tolerated alternate moisture regime and drying, as well as thawing and rapid freezing.

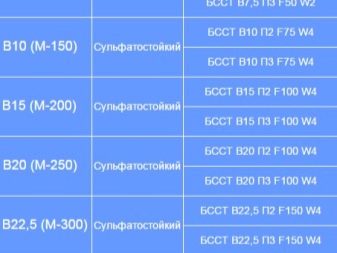

- Sulfate Resistant slag portland cement manufactured by mixing clinker with blast-furnace slag in granular form (approximately 50-60%) and a small amount of gypsum. The slag used for production must contain a limited amount of alumina (up to approximately 10-12%). Sulfate-resistant slag Portland cement is assigned to the brand M300 and M400. It is relatively resistant to the effects of sulfates, but does not tolerate severe frosts.

- Sulfate-resistant Portland cement has a brand M400. It is prone to slow hardening and low heat generation. It is universal and can withstand all kinds of temperature conditions and humidity.

- Sulfate-resistant cement with minerals about 15-20% of the total cement mixture of blast furnace slag in granules or 5-10% of mineral substances is added. This type of building material is available with the brands M400 and M500.Sulfate-resistant cement with mineral additives is excellent for the construction of various structures, has increased frost resistance and resistance to high humidity and drought.

Application

Due to the main components of Portland cement, which can be characterized as resistant to adverse factors of nature and harmful chemical compounds, the structures created with its use are durable and durable.

Portland cement is used to create sulphate-resistant concrete, as well as the following structures:

- sulphate-resistant piles;

- reinforced concrete structures;

- bridge piers;

- hydrotechnical buildings.

Special attention should be paid to sulphate-resistant piles in order to understand what it is. Piles are products that are large rods that are made from Portland cement. Their main application is the strengthening of structures and the creation of a solid support during the construction of the foundation.

The quality of these products entirely affects the durability and safety of buildings. Piles are buried deep in the soil. They are resistant to moisture, precipitation, groundwater and chemical elements in the soil cover.Most often they serve for the construction of large-sized bridges, hydrotechnical stations and dams.

Sulfate-resistant concrete can be made even from ordinary cement, if mineral mortar is added to the solution. However, it is better to use portland cement when creating a mixture for sulphate-resistant concrete. This will increase the strength of the structure at all stages, starting with the process of concreting and ending with guaranteed protection throughout the life of the concrete product.

Clinker composition

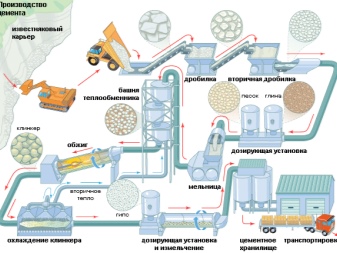

Clinker is an intermediate product in the production of Portland cement. It was first heard of in 1817 when French engineer Louis Vick invented cement clinker. This useful discovery helped later in 1840 to create artificial cement (Portland cement).

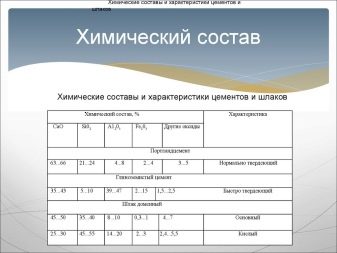

The composition of sulphate-resistant cement contains components of crushed clinker.composed of minerals. By production of material exact dosages of all necessary components are without fail considered. As a rule, finished products contain 5% aluminate and 50% silicate. This ratio is due to the fact that there are already quite a lot of sulfate compounds in the layers of the soil and precipitation.

When entering into a reaction with aluminate, the destruction of sulphates begins and, as a result, the deformation of the structure itself. For this reason, only a small amount of the aluminate phase should be present in the feedstock for the production of Portland cement.

The basic composition of clinker is greatly influenced not only by the feedstock, but also by the manufacturing conditions. When the raw material is burned, the impurities in it are placed randomly. This factor creates a changeable structure of clinker phases. Under the latter it is customary to mean base minerals: alit and belit.

- Alit is an important mineral that is of great importance in the composition of clinker. It quickly hardens and has high strength. Alit is very active in combination with water.

- Belit its reaction is less active, unlike alita. Also, its heat dissipation is two times less than that of the main clinker mineral, alita. Belit slowly freezes and due to this provides high strength material.

The basic intermediate substance involved in the creation of cement clinker is tricalcium aluminate. The content of this substance in the standard mixture of sulphate-resistant cement is only 5-10%.Excessive amounts of this material can provoke sulphate corrosion, as noted above. This process is fraught with negative consequences in the form of the destruction of the structure of concrete and the crystallization of salts on the walls of materials.

As for the last destructive impact, crystallization leaves its mark in the form of a noticeable expansion of the cement stone in volume. Sometimes the influence of sulfates leads to the formation of gypsum, which also contributes to a significant expansion of the stone and the gradual destruction of buildings.

The harmful effects of sulfates on reinforced concrete structures are noted with alternate drying and wetting of the soil and the structure itself. An example is the ever-changing level of water in a river. Reinforced concrete piles, made of sulphate-resistant cement, during this exposure to moisture undergo a slow eroding of the structure of the material and the deterioration of structures up to complete destruction.

Choosing cement for work, you should carefully examine its basic composition. It is important to consider that for each specific type of soil a special type of cement is needed.

How to do?

Getting sulphate-resistant cement is possible in two ways:

- make cement mortar with special additives from mineral substances;

- the use of a special zinc-sulphate cement-sand mixture made by an industrial method, which is durable and guarantees the protection of the structure during the entire period of operation.

In the manufacture of solutions should follow the exact ratio of components.

In the event that mineral additives are several times higher than the standard rate, the strength of the solution is significantly reduced, respectively, the fragility of buildings increases, due to which their destruction occurs. A solution of sulphate-resistant cement must comply with the basic norms of state standards.

Using Portland cement is an expensive procedure, so it is not used as often as a simple analogue. However, sulphate-resistant cement is simply incomparable in its characteristics with ordinary concrete mortar.

After all, the durability of Portland cement is several times higher than that of conventional materials.It should be noted that its main distinctive properties fully justify the high cost.

Sulfate-resistant cement reliably protects buildings and structures from the influence of moisture and frost, increases the wear resistance of structures. It can also significantly improve the quality of a simple concrete mortar, with the result that such a building material will last longer than the usual stated period.

To see how to properly mix the cement mortar, see the video below.