Fiber cement boards for facades: description and characteristics

The market presents a huge variety of materials for construction and repair. Even if you consciously limit the search to only options suitable for facades, the choice is very difficult. Any homeowner and novice builder will be useful to familiarize themselves with the properties of a promising fiber cement slab.

What it is?

Fiber plate helps to make the facade of the dwelling really flawless in appearance. Approximately 9/10 of the total mass of the product falls on cement, which makes it possible not to fear the deterioration of the ecological characteristics of the house. At the same time, excellent strength is guaranteed by the introduction of reinforcing fiber andfiber These additives allow to increase the operation time of the blocks and make them immune to corrosion processes.

Importantly, fibrolitovy plates do not light up, and it immediately distinguishes them from many other options for finishing the facade.

The material works perfectly both at high and at low temperatures. Biological and chemical effects that occur in everyday conditions do not pose a danger to him. Guaranteed and mechanical strength in general. The resistance to the action of visible and ultraviolet radiation is also beneficial for consumers.

Fiber cement is twice as light as ceramic granite when compared with siding, while lightening the load on the foundation does not mean less reliability or heat loss. The material itself is cleaned, the main types of contamination are destroyed when in contact with fibrous cement, after which rain or snow flushes their remains down.

Options

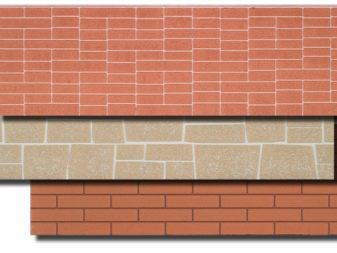

Fiber cement board has not only impressive technical characteristics. It is able to imitate the appearance of natural stone, including granite. Mounting the plates is quite simple.if there is at least minimal experience and basic construction skills. But if there is no complete confidence in their abilities, it will be more correct to turn to professionals for help.

The main advantages of this coating are the following:

- minimal risk of lime on the walls, because the blocks are made using an autoclave;

- the disappearance of the need to prepare the wall and correct its shortcomings;

- affordability at comparable properties with more expensive counterparts;

- the ability to trim the facade in any season;

- cover of the main construction material from negative meteorological impacts.

Modern technologies allow the use of fiber cement blocks for the implementation of the most intricate design solutions. There are all possibilities to choose the perfect tone or texture of parts. Unfortunately, there is no way to purchase a fiber cement board with a thickness of 8–9 mm, the maximum figure is 0.6 cm; the width of the parts varies from 45.5 to 150 cm, and the length from 120 to 360 cm. The popularity of such solutions is also due to their ease: a single unit is never heavier than 26 kg.And this not only simplifies construction, but also makes it possible to dispense with any lifting equipment.

It is very important to remember about the high rate of water absorption. It reaches 10% of the mass of the product, which leads to deformations up to 2% (insignificant for strength, but which can affect aesthetics and the state of neighboring blocks and seams). Finally, the fiber-cement block is not sawn or cut by hand, so an electric tool should be used.

It is with the mass of the structure that its fundamental disadvantage is connected. In principle, it is possible to lift such a block alone, but it is unlikely to be convenient and easy.

Where can I use?

- Fibrocement-based slabs showed themselves from the best side, where it is required to imitate natural stone at a low cost and with minimal load on the foundation. Solutions that look like brickwork are equally in demand.

- The fiber-cement plate is excellent for facades of baths and for finishing the internal rooms in them. Such constructions have excellent resistance to fire. And some manufacturers further strengthen it, seeking maximum security.

- Many people have already appreciated all the advantages of mounted facade designs. A large and lightweight slab allows you to complete all the work in the shortest time possible, to close the slightest flaws in the building's surface. In production, these blocks are hardened, and they become very durable. Since the outer side is covered with acrylic and polyurethane, there is no risk even when installing near a reservoir or in places where heavy precipitations fall.

- To create ventilated facades made of fiber-cement slabs, no special effort is needed.

Laying without gaps produced by a similar technology. The difference is that you can confine a single crate and put the panel directly on the insulation. Such a measure can reduce labor costs and reduce financial costs. Regardless of the method chosen, preliminarily calculate the need for materials.

To work you need the following tools:

- profiles of various types;

- self-tapping screws;

- dowel-nails;

- accessories completing the external composition of the panels.

Manufacturers Overview

- Fully Russian product "Latonite" can not be named. In its production uses the latest developments of foreign firms.But this is only a plus, as the company continuously improves the product and periodically adds new versions to its range.

- If you need products with maximum resistance to fire, it is recommended to pay attention to the modification Flamma. It perfectly manifests itself not only in the exterior, but even next to a hot stove.

- Quality Finnish version is, of course, "Minerit". Slabs supplied from Finland are not only decorative, they increase the thermal efficiency of buildings.

- But the fiber cement of the Japanese brand "Nichi" It should be chosen by those who want to avoid shrinkage after installation and immediately proceed to the finish. Another brand from the Land of the Rising Sun Kmew can not boast of such a characteristic. It is being released for the fifth decade and has absorbed the abundant experience of developers.

- If you go back to Europe, you should pay attention to the Danish Cembrit, proving in deed year after year compliance with the most stringent standards.

- But the use of blocks can also be of considerable benefit. Kraspan. The company has focused its efforts on the production of finishing materials for the facade and has already opened more than 200 representative offices in Russia. So, you can buy goods directly, without intermediaries almost everywhere.

- "Rospan" - This is another attractive domestic brand. In its assortment there are far from some fiber cement plates.

How to choose?

When choosing fibrotsementnyh plates there are a number of subtleties, about which sellers are usually silent.

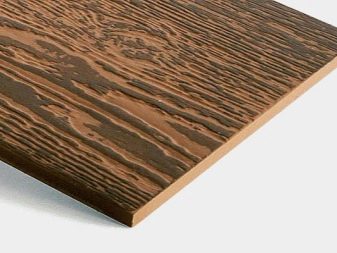

- So, a part painted in production will be more expensive, but the unpainted will still have to cover paint and varnish, and doing it manually is not too easy. It will be easy to conform to the fashion if you buy blocks from fiber cement imitating decorative plaster. Especially popular among designers covering "Oak bark". Quite good results are also provided by the use of the decor “Flock”, “Mosaic”, “Stone Crumb”.

- When choosing it is useful to pay attention to the density and the specific gravity of the material, on its natural or artificial components. It is very important to think about the appropriate dimensions and geometric shapes of the coating. In addition to the plates themselves, we have to choose decorative strips for them. The preference of color for the tone of the main wall or in contrasting colors depends solely on personal taste and design concept. If the typical dimensions are not enough, you can order longer and wide strips, but not more than 600 cm.

For horizontally and vertically directed seams, as well as for decorating corners, there are special types of slats. Assessing the need for them, you need to pay attention to the following features:

- the overall height of the building;

- dimensions of the plates;

- number of angles;

- the number of windows and doors, their geometry.

- The slab structure does not need to be smoothed. There are options that add marble particles or create a relief. The most practical size is with a width of 8 mm; products with a width of 6 or 14 mm are also often purchased. If you need to get unusual dimensions or custom design will have to submit an individual order. This will necessarily affect the timing of work, and its cost.

- In the most critical places and when finishing the facade of the bath It is recommended to use smooth plates with a paint layer treated with flame retardants. Covering with stone plaster will appeal to those who are looking for blocks with the longest possible service life. In addition, it is stronger than other options.

Fiber cement siding "breathes". But at the same time, it surpasses a simple tree in fire resistance, form stability in various weather conditions and resistance to aggressive insects.

Lining instructions

Installation of various types of fiber cement boards, if different, is negligible. The general technological approaches are stable in any case. The first step is to thoroughly prepare the surface. Although it is formally considered that it is possible not to resort to it, responsible builders and experienced professionals never risk doing so. Removing the old coating and exposing the smallest irregularities, dismantle any parts protruding beyond the contour and repair the damage.

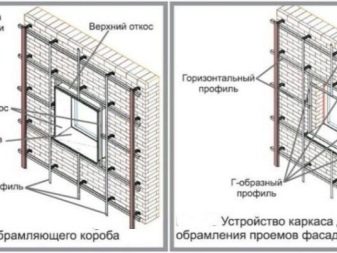

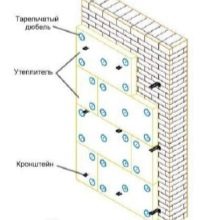

The next step is to place the tags where the brackets will be mounted. Installation distance is 0.6 m in the vertical and 1 m in the horizontal plane.

Most professionals and even experienced home craftsmen make metal subsystems because the wood is not reliable enough. However, this largely depends on personal choice and on what is available to performers.

Before finishing the house of fiber cement siding is required to prepare the insulating layer.

A typical solution in this situation is the use of fiberglass fastened to dowels with a wide head. The plates themselves are attached using brackets or nails.Choose the appropriate method, focusing on the thickness of the blocks.

Acquire panels should be with a margin, even a simple cutting to the exact size can cause a loss of 5-7%. The gaps of the plates required to close the separating bars, otherwise the most even joint not get.

In order to keep the facade surfaces attractive for a long time, it is recommended to cover these strips with a layer of sealant on top. You should not try to mount fiber cement panels using “wet” technology, it will only ruin everything. Doing the work with your own hands, you need to choose such dowels that will sink at least 3 cm into the material. From insulation to used plates always leave a gap of at least 4 cm. The upper strip of the panels is equipped with a ventilated substrate, which provides effective air circulation. At the outer corners they put steel corners in the color of the main coating.

When mounting with grooves, clamps are used, and only the attachment of the thinnest elements to the frame profiles vertically is done by self-tapping screws.Supplemented with sealing tape. The mounting pitch is then reduced to 400 mm vertically.Where the panel is mounted, there must be a hole at least 50 mm from the outer edges of the material. It is not allowed to create very large gaps both vertically and horizontally. They should be at the most 0.2 cm. Horizontal ligaments, where decorative ebb is applied, are allowed to be made with a gap of 1 cm.

You will learn more about the installation of fiber cement boards in the next video.