Extruded polystyrene foam: what is it and how is it used?

Currently, most construction and facing works are not complete without the use of foam materials. One of them is extruded polystyrene, which is popular today. Today we will talk extensively about what it is and how this material is used.

What it is?

Today, the range of various finishing materials is so great that in its wealth you can just get lost.So, one of the most popular coatings with many positive qualities is extruded polystyrene.

This product is a special material of synthetic origin, which was first published in the USA in 1941. Now polystyrene is used in the most different purposes. It is to these raw materials that are applied during the thermal insulation of structures such as foundations and roofs. In addition, extruded polystyrene is in good contact with facade plaster.

Production features

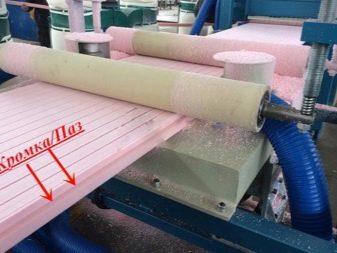

Drawing attention to the name of this popular material, we can conclude that it is one of the forms of more advanced processing of foamed polymeric raw materials, which is obtained by the condensation of styrene under the action of catalysts under conditions of organic solvents.

The operational characteristics, as well as the advantages and disadvantages of this materials are due to the process and its production.

- First, the raw material is taken, represented by small particles placed in the reactor. There, under conditions of high temperatures and pressures, these components are saturated with special gaseous constituents.

- After the pressure is released, the mass begins to expand rapidly, like foam. At the same time, it gradually cools down and acquires all the properties necessary for a solid.

- Hot and melting mass is passed through extruders. Thanks to these actions, polystyrene becomes more dense and similar to laminated plastic.

As a result of these stages of work, a special extruded material is obtained. In its immediate structure, polystyrene takes only 1–2%. The remaining components are air, purified from water vapor, for which the characteristic minimum thermal conductivity.

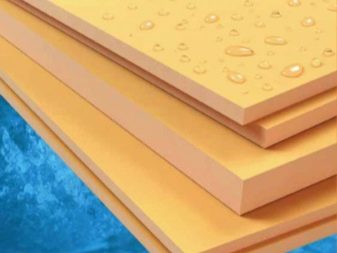

The main feature of extruded polystyrene (EPPS) is its zero transmission of moisture and gases. This modern and high-tech material does not pass water vapor through its structure, such as, for example, the well-known mineral wool. Over time, polystyrene is not filled with water and does not lose its insulating characteristics. Such problems will not be encountered even if the installation of the material was not entirely correct, and the dew point fell on the surface of the insulation.

Difference from polyfoam

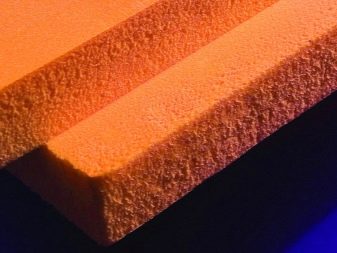

Extruded polystyrene is the same plastic, characterized by a more homogeneous structure, in which there are many closed cells - their size is about 0.1–0.2 mm. By mixing all the necessary components and passing them through an extruder, even colorless or colored sheets are obtained. After complete drying, these materials can be used as intended.

Extruded polystyrene foam has quite a lot in common with foam. These products have a similar chemical composition, the main component of which is polystyrene.

As for the functional component, here EPS and foam plastic can not be compared. Polyfoam during production does not pass through an extruder, and for expanded polystyrene it is a standard procedure. In this case, extrusion gives this material a completely different transformation and, therefore, completely different performance characteristics.

Advantages and disadvantages

Today extruded polystyrene is known as a reliable and practical material that can be trusted. Its relevance is due to many positive qualities, which should be discussed in more detail.

- This material is waterproof. In case of unfavorable contact with the liquid, the polystyrene foam floors are filled - no further movement of moisture occurs.

- Extruded polystyrene is characterized by a low level of thermal conductivity. If we compare it with other insulating coatings, we can conclude that the thermal conductivity coefficient of the EPSI is less than or equal (the only exception is polyurethane foam).

- A characteristic feature of EPPS is low vapor permeability. The coefficient of this parameter is considered the minimum among the insulating components.

- Expanded polystyrene is not subject to deformation, even after a very long time.

- This material is not afraid of temperature jumps. In such conditions, it does not lose its useful qualities and remains as practical / effective. Its working temperature ranges from -100 to +75 degrees.

- Installation, as well as the dismantling of polystyrene foam is a simple matter, and it takes not so much time as it seems to many.

- This material boasts a long service life, during which it is not deformed and does not lose its qualities.

- In the course of operation extruded polystyrene is not subject to destruction.

- Extruded polystyrene foam is not afraid of inorganic solvents.

- Working with this material is very easy and simple, since it is light in weight and light in thickness.

- Such material is relatively inexpensive. It will be able to afford many consumers. In this case, the ratio of price-quality can not but rejoice.

- When laying EPPS, it is possible to dispense with the use of additional hydro and heat insulating coatings, which will allow significant savings.

- According to experts, EPPS is not dangerous to human health. Moreover, when working with him, the master will not have allergic reactions.

- Such material is not afraid of low temperatures, so it is ideal for being in a harsh and changeable Russian climate.

- The durability of extruded polystyrene is confirmed by the fact that it is not subject to rotting - not every building and finishing material can boast of this quality.

As you can see, the advantages of EppS very much. That is why today it occupies one of the leading positions in the market of insulating materials. However, this practical and reliable coating also has its drawbacks, which should also be known before purchasing it.

- This material is subject to burning.

- Being in conditions of temperatures above 75 degrees, polystyrene foam can release harmful substances hazardous to human health.

- According to experts, this material is afraid of contact with infrared rays.

- In the EPS, mice can start, although many manufacturers deny this fact.

- When interacting with various solvents, this material may deteriorate.

If the listed disadvantages do not frighten you, then we can safely proceed to the acquisition of this modern material - it is used in many areas.

Properties and specifications

Currently, extruded material produces many large and well-known manufacturers. As a rule, the performance characteristics and properties of different products almost do not differ from each other. This also applies to their dimensional parameters.

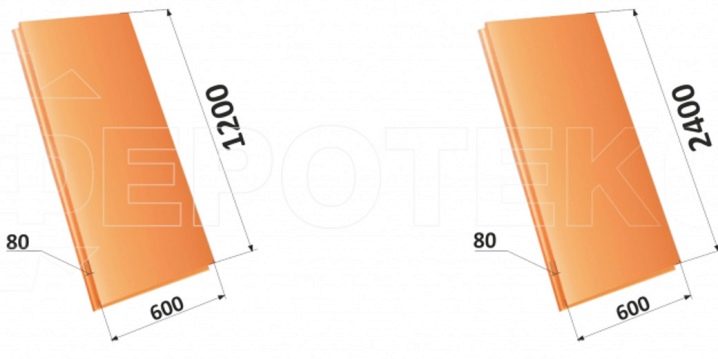

- Thus, the thickness of polystyrene foam plates most often ranges from 20 to 150 mm.

- Standard dimensions of polystyrene foam plates are - 600 x 1200 mm, 600 x 1250 mm, 600 x 2400 mm.

- Their level of thermal conductivity can range from 0.03 to 0.032 W / ms.

- As for the density index for compression, at 10% linear deformation it is 150 x 1000 Kpa.

- The percentage of moisture absorption is usually 0.2–0.4%.

- Flammability class from G3 to G4.

- The vapor permeability level is 0.013 Mg.

- Density - 26–45 kg / cu. m

Manufacturers and sizes

Modern manufacturers produce extruded polystyrene foam with various technical characteristics. Currently, there are three leading brands whose products are considered the most popular and common:

- Penoplex;

- Technoplex;

- Ursa.

Let us consider in detail what characteristics and properties the XPS has of these manufacturers.

Expanded polystyrene "Penoplex" - is a popular domestic product that is found in many stores and is in great demand. Such materials are used for civil and industrial construction. Let's get acquainted with the main characteristics of polystyrene foam of this company.

- The thickness of EPS "Penoples" can be - 2, 3, 4, 5, 6, 7, 8, 10, 12, 15 cm.

- Sheet dimensions are - 60 x 120 cm, 60 x 240 cm.

- The level of thermal conductivity is 0.03-0.032 W / m C.

- Compressive strength is 0.2–0.5 MPa.

- The level of water absorption does not exceed 0.4%.

- The material combustibility class is G4.

Ursa is a large international company with representative offices in Russia. At the moment, this manufacturer produces three types of extruded polystyrene foam. Materials "Ursa" have the following specifications.

- The thickness of the materials is 3, 4, 5, 6, 8 and 10 cm.

- The length and width of all sheets of EPPS is the same and is 60 x 125 cm (other sizes are also on sale, for example, 50 x 600 x 1250 mm).

- The thermal conductivity level of EPPS sheets is 0.032–0.034 W / m C.

- Compressive strength is from 0.25 to 0.5 MPa.

- The material absorbs moisture by 0.5%.

- Flammability class G4.

"Technoplex" produces polystyrene sheets with the following parameters.

- Their thickness can be 3, 4, 5, 10 cm.

- All sheets have standard dimensions - 60 x 120 or 58 x 118 cm.

- They are characterized by a high coefficient of thermal conductivity.

- Materials from Technoflex are 0.2% worse at absorbing moisture than raw materials from Penoplex.

The products of these brands are in great demand in our country and meet all state standards.High-quality polystyrene foam of these companies is in demand due to the excellent performance characteristics, long service life and simple installation.

Of course, this is not all the major manufacturers whose products are popular today. For example, today KTplex, Ecotherm, Onda, TechnoNikol (a popular product - XPS) and many others are no less in demand.

If you want to buy really high-quality polystyrene foam, then you should contact a trusted company store. Do not look for too cheap materials - EPPS is already an affordable heat insulator.

Where does it apply?

Extruded polystyrene foam is used in various fields due to its positive qualities and performance characteristics.

- This material is very useful in private construction. With its help, both internal and external insulation of floors of houses is produced. In addition, they can insulate roofs, communications lines and even basements. Often this material is addressed in the course of waterproofing works.

- EPPS is a popular material in state industrial construction.It is ideally suited for high-quality thermal insulation of various buildings, underground premises, as well as various trunk lines.

- Useful polystyrene and when laying highways or large runways.

- Used EPPS with the release of refrigerators and refrigerators.

- Extruded polystyrene foam is a wonderful material, which is often used in the construction of buildings of economic direction. These include large vegetable stores, farms, greenhouses of various sizes, as well as greenhouses.

For whatever this popular material is used, its main focus will be the insulation of wall ceilings, foundations and roofs.

Insulation technology

Extruded polystyrene foam is very popular not only because of its excellent performance, but also its long service life, as well as easy installation / disassembly. You can install it on various bases with your own hands, without turning to teams of specialists.

The main thing is to stick to a simple technology of work, and then the result will not disappoint you!

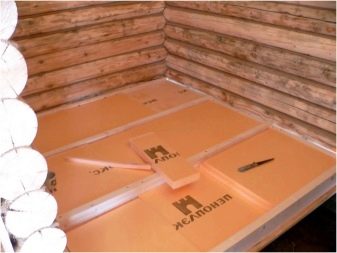

Paul

Many people choose to warm the floor in the house with expanded polystyrene.The method of its installation largely depends on the material of the base, and on its type, and on the immediate requirements that are imposed on it.

On the ground

Epps are often laid on the ground floor, located on the ground floor, when it is planned to install laminate, parquet, ceramics or linoleum on such a base. Expanded polystyrene is perfect for the future arrangement of a spectacular self-leveling floor.

To insulate such a floor, you need to properly prepare the foundation. It should be strong enough.

In addition, the floor should not shrink in the future. To do this, the ground level must be 50–60 cm below the design level of the surface of the future floor covering. You should also take into account the fact that the base must be completely dry and rammed.

When the foundation is prepared, the first layer of dry rubble is laid on it (gravel can be used instead of rubble). The height of such a coating should be about 30–40 cm. This layer should also be properly leveled and compacted.

Then over the rubble you need to lay out a layer of granite sifting or Mediterranean sand. The height of this layer should not exceed 10 cm.From above it needs to be leveled. To control the process, you should use the building level.

In rooms where there will be no high mechanical loads, foam polystyrene plates can be laid directly on the sand base. In this case, it is recommended to buy materials that have connecting grooves located on the edges. As for the joints of the plates, they are recommended to pre-glue the special metallized adhesive tape.

The thickness of EPS sheets can be from 3 to 10 cm - it all depends on the living conditions and the level of insulation of the foundation of the house.

When you lay a substrate on the floor, its surface should be covered with waterproofing material. Next, you need to make a reinforced cement-sand screed. Always check the flatness of the surfaces. It is possible to proceed to laying the floor slab only after the complete drying of the screed.

If styling of polystyrene is planned in a room where the floor will be subjected to severe mechanical loads, then before installing the insulation boards, you must install a concrete screed (sand and gravel pads and waterproofing).Plates Epps can be laid on the base only after its absolute drying.

On concrete

If you are going to warm the concrete floor, then you need to make sure that its surface is flat - without drops. Any cracks and cracks also need to get rid of.

If the concrete base is the overlap of the basement or basement, the insulation is recommended to be laid over the waterproofing film.

Styrofoam, though not afraid of moisture and moisture, but these components can penetrate to the junction of the plates, so the excess waterproofing in this case just will not be superfluous.

If irregularities are present on a concrete base, then you first need to get rid of them, as well as seal all cracks and cracks. Make a leveling sand-cement screed. When the latter is dry, it is necessary to lay the EPS on it, and already on this layer - waterproofing. It is recommended to install heat-insulating plates on a special glue intended for ceramic tiles. On top of the waterproofing make a coupler.

Insulation with expanded polystyrene can be floors in an apartment on the balcony or on the loggia.All work should be performed on the same principle as the above. However, it should be borne in mind that it is only possible to proceed to a similar arrangement of the floor in the unglaced area if the temperature is kept there not lower than 5 degrees.

As for the glazed area, you can start work on it even if the temperature in this place is below 5 degrees. However, then you need to additionally insulate the area being repaired, so that the screed has dried to the end and you can lay foam polystyrene plates on it.

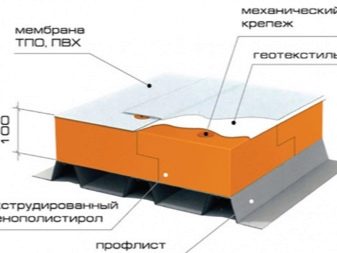

Roofs

High-quality insulation is necessary not only the floor, but also the roof. In this case, it is also permissible to use extruded polystyrene foam. In this case, his plate must be properly decomposed under the roofing material.

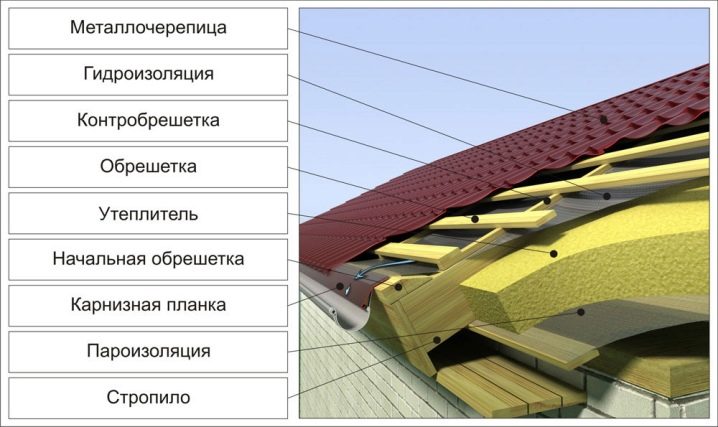

Consider what should be the order of arrangement of all the constituent elements (we look from the inside - outside):

- first comes a decorative coating (the roof itself);

- then follows the internal lathing designed to support the insulation and ventilation material on itself;

- vapor barrier film;

- insulation;

- waterproofing film;

- external lathing required for additional ventilation and installation of roofing;

- roofing.

Many home masters at the same time neglect the installation of steam and waterproofing films. This is a big mistake, since these components will protect from moisture and moisture not only the heat-insulating layer, but also the roof construction made of wood.

Also, insulation of the roof of the EPS can be made already on the finished structure. Consider what you need to do:

- install waterproofing material on rafters;

- then fix the insulation on special hangers;

- close the insulation vapor barrier coating;

- nail the lattice with nails to the rafters (this frame construction will retain all insulation and also play the role of a ventilation area);

- Finally, install the trim material.

In this case, you need to take into account one drawback - when installing polystyrene foam on an already finished roof, you will scrape a certain amount of usable area. In the case of leakage, such a construction will have to be changed to a new one.

Foundation

By means of expanded polystyrene it is possible to warm also the base.To do this, too, should adhere to a certain technology. We will get acquainted with all the necessary stages of such work.

- First you need to correctly prepare the foundation. It is possible to insulate such structures both under construction and ready-made buildings. Make sure that the foundation is completely dug out and cleaned of dust, grease, construction waste and other defects.

- If there are remnants of the old waterproofing on the foundation, then you also need to get rid of them.

- Keep in mind that such a basis can be insulated both outside and inside, however, external insulation is considered more effective.

- Pick the right styrofoam. For the foundation, it is recommended to buy materials whose density is 35 kg / cu. m. Flammability class in this case is not so important.

- Do waterproofing the foundation. In this way, you can prevent materials from becoming wet during the onset of groundwater.

- Waterproofing can be installed under the insulation in any way. The only exception is the isolation of the base with the help of a special bitumen fill - EPS in contact with solvents can suffer greatly and even collapse.

- Next, you will need to attach polystyrene to the foundation (its underground component). At the same time the warming plates are fixed on a special glue designed specifically for expanded polystyrene.

- The adhesive mixture should be applied around the perimeter of the plate and in its center with several stripes. Then you need to wait about 1 minute and press the polystyrene foam to the base. Wait a couple of minutes and proceed to the installation of the next part.

- It is recommended to mount the plates using a level so that there is no distortion at the joints.

- If you need a thicker insulation, then polystyrene foam is allowed to install not in one, but in two layers. In this case, the plates must be glued in such a way that the second layer necessarily covers the joints remaining between the tiles of the first layer. If, however, after the installation of the gap on the material remained, they must be closed with a conventional mounting foam.

- Next you need to protect the insulation itself. To protect the expanded polystyrene from mechanical damage and the attack of rodents, it is recommended to add this material on top with a reinforcing mesh or special shields. These components need to be fixed around the perimeter of the foundation with the use of dowel-nails.

On top of the mesh, the foundation can be covered with a cement mixture with the addition of special waterproofing ingredients.

- If the house is on wet ground, it is necessary to provide high-quality drainage. It is installed along the entire perimeter of the foundation and placed in a valley or a special well.

- Next you need to make insulation basement. This part of the foundation also needs additional warming. Now the previously prepared surface, protected from the penetration of dampness and moisture, is ready for laying EPSs. They should be mounted on the same adhesive composition.

- After a couple of days, the foam polystyrene plates are recommended to be additionally fixed on the base with a special fastener (for this, dowel-nails with wide caps are suitable).

- After these works, you can go directly to the insulation of the soil (this process is described above).

Walls inside

Insulation of walls with expanded polystyrene from the inside implies the observance of a certain technology. Consider the stages of such work.

- First you need to prepare the grounds. It is necessary to thoroughly clean the surface of the floors.Be sure to remove the old coating, especially if it is paints. Otherwise, the solvents in their composition will destroy the structure of the insulation.

- Next you need to align the surface of the walls. If the floors are made of brick, then they need to be plastered, and if it is made of concrete, then you can do without plaster. To fine-tune the base, you must first put an acrylic primer using a paint roller.

- After that, the layer will dry for 12-14 hours. Repair any defects on the walls with a putty. Then apply another layer of soil. Thus, you complete the preparation of wall ceilings.

- Now you can proceed to the installation of polystyrene plates. To do this, you can use a special adhesive. It may be dry or already prepared.

- It is permissible to apply the glue with a brush, or you can use a roller by swiping them along the surface of the walls.

- In this case it is recommended to install the plates from the bottom. For a start, they need to carve out in size - for this they can be applied to the still dry floors. Cutting polystyrene is better with a hot string or notched jigsaw.

- The first row of slabs should be installed all over the wall.After that, you can install the next row.

In this case, the plates need to be shifted relative to the lower elements so that the joint between the first-row sheets falls on the middle part of the upper plate.

- Let the glue dry thoroughly. It may take 34–42 hours.

- It is recommended to additionally fix the installed insulation using dowels. In this case, the walls must be drilled right through the EppS. Then in the resulting holes need to hammer dowels. Heat-insulating material should be attached with screws. Large sheets can be installed in 6 locations.

- Now you should go to the sealing of the seams. If their dimensions exceed 30 mm, then they can glue the remaining trim polystyrene foam.

- At the end of all work joints need to be treated with foam. Make sure that it does not contain toluene - this component corrodes the plastic.

Excess mortar should be quickly removed with a knife, then the seams must be treated with adhesive mortar.

- Now you need to apply a reinforcing layer (for example, a fiberglass mesh).

- Put on top of protective coatings, as well as vapor and waterproofing.

- At the end, cover the walls with a finishing coat, such as plaster.

Facade

Many people turn to the insulation of EPS facades of houses. This work should be done as follows.

- At first, the walls outside are scrupulously cleaned of everything superfluous, as well as the former finishing materials, especially if it is paint.

- If the overlap have irregularities, then you must get rid of them. This also applies to various damage, such as cracks or crevices.

- Now you need to apply glue to the polystyrene plates (no need to apply too thick a layer), and then you need to press these parts tightly to the bases and additionally attach them using dowels.

- Attach polystyrene plates to all facade surfaces.

- After that, sheathed foundations need to be thoroughly polished.

- Install the reinforcing mesh on the entire area of the installed insulation. Drown it in a sticky solution.

- Next, be sure to wait until the surface covered with plaster is completely dry. Until then, no work can begin.

- After complete drying, the substrate must be coated with a high-quality primer.

- Only now it is permissible to go directly to the decoration of the facade. For such bases, it is recommended to purchase only high-quality and high-strength coatings that are not afraid of temperature changes and precipitation.

Warming of the facade is recommended only in the warm season. During such periods, the humidity of the air is significantly reduced, so the adhesive and cement compositions adhere much better, and dry out - very quickly.

Review of some heaters (foam, extruded polystyrene foam and PIR), see the following video.