Penofol: what is it and what is it for?

For insulation of residential and non-residential buildings used a variety of building materials. Penofol is also used as a heater. Consider what this material is, what are its advantages and disadvantages.

What it is?

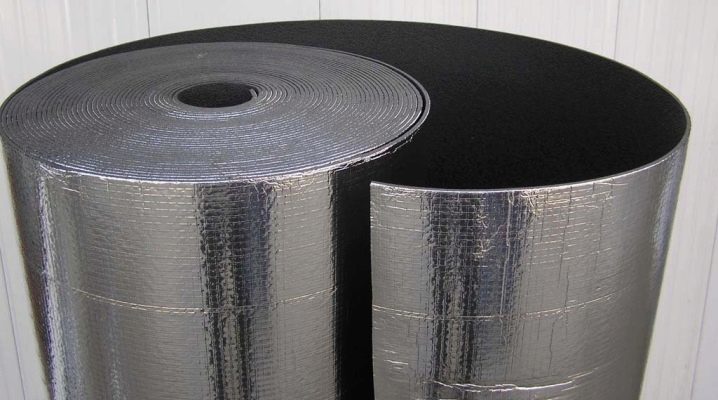

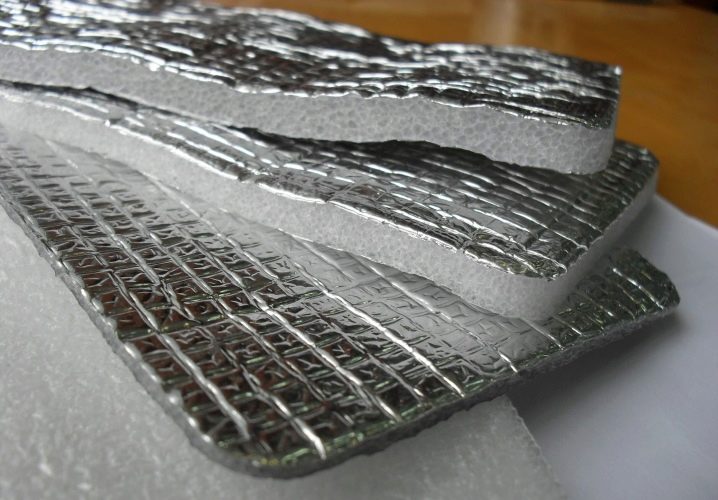

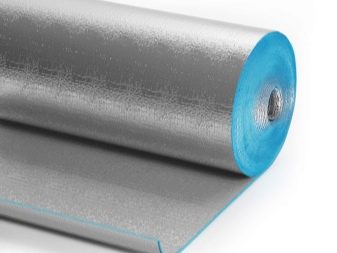

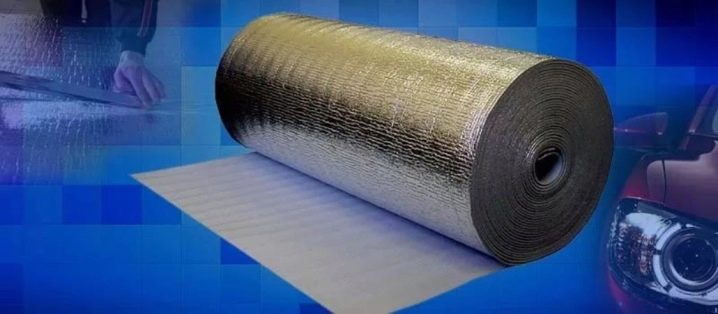

Penofol is a two-layer heat-insulating building material that can be made from one or 2 layers of foil deposited on a base layer of polyethylene foam. Depending on the type of product, the density and thickness of the foam may vary. Utilitarian and inexpensive insulation is in great demand among buyers, because it has high performance characteristics.

The foil layer, whose thickness is 20 microns, provides penofol excellent heat-reflecting qualities.

This insulation is used in everyday life and industry as the main insulating material or as an auxiliary insulating layer.

Penofol is used as the main insulating material in cases where it is necessary to insulate a room with normal heat loss and where there is a powerful source of heating (bath, sauna, floor heating system in a wooden house). Penofol is used as an additional heat-insulating building material when creating complex heat insulation in residential and industrial premises, and such rooms must be equipped with vapor barrier and waterproofing.

Advantages and disadvantages

The use of penofol has its advantages:

- The small thickness of the material allows you to create reliable insulation of the room.

- Installation of building materials does not require special skills and special tools. Working with such material is much easier than with other types of insulation.

- The material is environmentally friendly, which makes it possible to use it for food storage.

- Fireproof. This building material belongs to the class of fire-resistant materials.

- Convenience during transportation.The thickness of the product allows you to fold insulation in a roll that allows you to transport it in the luggage compartment of the car.

- Excellent sound insulation. Mounting penofol over the frame of building structures provides good isolation of extraneous sounds.

Penofol possesses not only positive qualities. There are also disadvantages of using this building material:

- Insulation has softness. Because of this, this product is not used for finishing plastered walls. With light pressure, the material flexes.

- To fix the insulation will require special adhesives. It is not recommended to nail it to the surface, because in this way penofol loses its thermal insulation qualities.

What material is better?

As you know, heat transfer from the product to the product is transferred. 3 ways:

- heated air;

- thermal conductivity of materials;

- radiation - the transfer of heat from one product to another occurs through the use of electromagnetic waves of the infrared spectrum.

Consider some differences penofola from other insulating materials.

Most heat-insulating building materials (mineral wool, izolon, penoplex, tepofol) prevent one of the types of heat transfer. A distinctive feature of the foiled material from other types of insulation is that it has a complex effect: polyethylene foam is an obstacle to convection, and thanks to aluminum foil, the thermal reflection index reaches 97%.

Penofol can be compared with only one group of heat-insulating materials - izolon. Comparing izolon and penofol, there is no significant difference in the quality and method of their use. To determine the winner, you need to look at the availability and price category of a building material. The only advantage of izolona is that the assortment is expanded with sheet building materials, whose thickness ranges from 15 to 50 mm.

Penofol is mounted with glue, and fixing of penoplex is carried out by means of fungi self-tapping screws. Also, foil insulation does not accumulate heat, but rather reflects it.

Minvata is mounted only on vertical slats. The price category of penofol is significantly lower than that of mineral wool.

Specifications

Consider the main technical characteristics of insulation, thanks to which it is in great demand among consumers:

- The temperature range for working with a warming product for all varieties of penofol varies from -60 to +100 degrees.

- The size of thermal shielding of the foiled layer ranges from 95-97 microns.

- The level of thermal conductivity of the material: type A-0.037-0.049 W / micron, type B-0.038-0.051 W / micron, type C-0.038-0.051 W / micron.

- Moisture saturation with full immersion in water for a day: type A-0.7%, type B-0.6%, type C-0.35%.

- Weight (kg / m3): type A-44, type B-54, type C-74.

- The coefficient of elasticity with a load of 2 Kpa, MPa: type A-0.27, type B-0.39, type C-0.26.

- Compression level at 2 Kpa: type A-0.09, type B-0.03, type c-0.09.

- The elasticity of all types of penofol does not exceed 0.001 mg / mchPa.

- Heat capacity of all types of building materials is 1.95 J / kg.

- Compressive strength level - 0.035 MPa.

- Flammability class: G1 according to GOST 30224-94 (slightly combustible).

- Flammability level: B1 according to GOST 30402-94 (flame-resistant).

- Sound absorbing properties - not less than 32 dB.

The range of penofol is represented by the following products:

- С-08 15000х600mm (packing volume 9 sq. M);

- C-10 15000x600x10 mm;

- C-03 30000x600 mm (18 sq. M);

- C-04 30000x600 mm (18m2);

- C-05 30000x600 mm (18 sq. M).

Kinds

There are 3 main types of penofol, depending on the production technology, dimensions and technical characteristics:

Type A

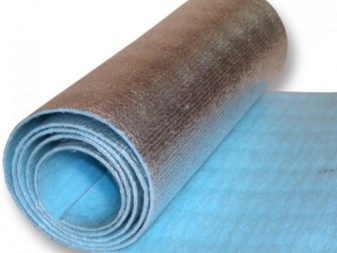

Polymer insulation material of different thickness, the foil is applied only on one side of the building material. This type of tile is popular in complex insulation of building structures, it can also be combined with some heaters: glass wool, mineral wool.

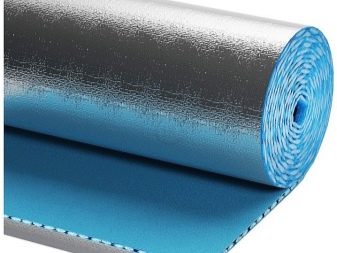

Type B

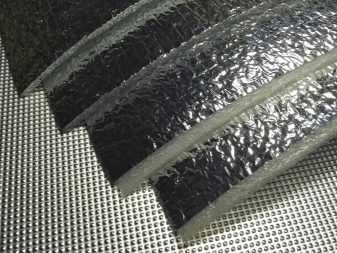

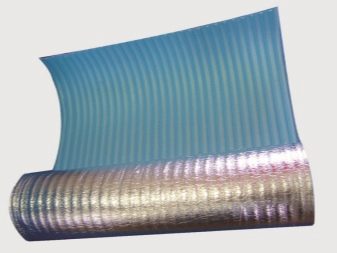

Insulation, covered with foil on both sides. Thanks to this design, the material has a maximum warming effect.

This type of insulation is used for thermal insulation of attic structures, waterproofing basements, floors and walls. The foiled material laid under the roof prevents heat from entering the room.

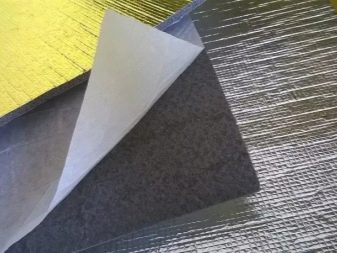

Type C

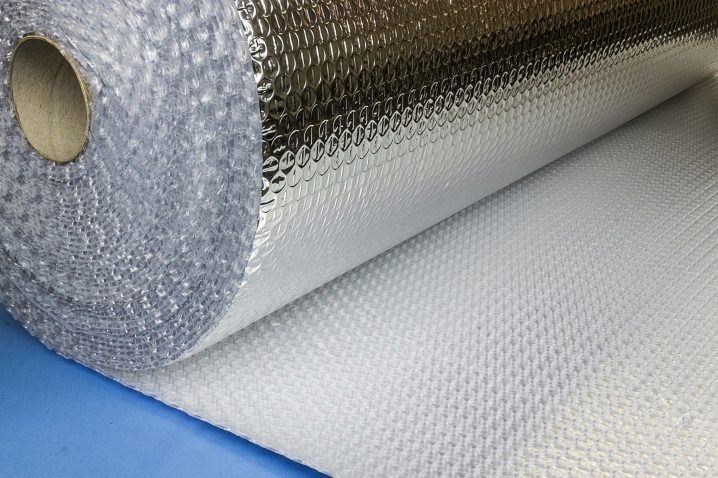

Self-adhesive penofol, which on one side is covered with foil, and on the other, a thin layer of adhesive coated film is applied to it. Depending on the dimensions of the product it is used on almost any surface, which saves time. Before starting work, this building material must be cut into strips of a certain size.

Normal penofol (types: A, B, C) has a base of white color, while in penofol 2000 it is blue.

There are several other types of penofol that are not in great demand among consumers.

Type R

One-sided insulation, which has a relief pattern on the foil side of the insulation. It is similar to penofol type A, but mainly used as a decorative element for interior decoration.

There is a penofol without foil coating, which does not have the appropriate type, but the builders call it a laminate substrate (linoleum).

This type of insulation has a low cost, and is mainly used for thermal insulation of floor special coating.

Insulation with a narrow direction:

- ALP - material laminated with polyethylene film. It has a high reflective performance. It is used for insulating incubators.

- NET - this type of insulation is similar to type B, it is produced in narrow roll sheets. Used for pipe insulation.

A novelty in the manufacture of polymeric insulating materials is perforated penofol. Such a building material is able to breathe, because it has a large number of micro-holes. Often used to isolate wooden structures.

Dimensions

Penofol is available in rolls of various lengths, the maximum value of which is 30 m. The width of the canvas varies from 0.6 to 1.2 meters. The thickness of the material depends on the type of penofola. Standardized material thickness: 2,3,4,5,8,10 mm. In rare cases, materials 40 mm thick are produced.

Foil material, whose thickness is 1 cm, has a high level of protection against noise and retains heat much better. Very popular insulation thickness of 5 mm, which has high technical characteristics.

Penofol is available in rolls. The standard length of a rolled sheet depends on the thickness of the building material and can be 5, 10, 15, 30, 50 m.

Application

Scope of use of a penofol extends not only to internal warming, but also external. Also, this type of insulation is used for the insulation of residential premises, civil and industrial production:

- country house or apartment in a high-rise building;

- roof;

- ceiling coverings;

- attic space and attic;

- basement and basement facilities.

- floor heating system (water, electric) and roof insulation;

- facades of buildings;

- water and air pipes;

- insulation of refrigeration facilities;

- ventilation system and air ducts.

Sometimes foiled material paste over the wall where the battery is located. This is done so that the heat is not absorbed by the wall, but goes inside the room.

Penofol is in great demand among motorists. With the help of such insulation, sound insulation and sound insulation of bodies of cars and trucks (KAMAZ cabin) are performed.

Three varieties of penofol are used for domestic needs: A, B, C. The scope of this material as a thermal insulation material is very extensive: walls, ceiling, floor, insulation of concrete surfaces, loggias, insulation of wooden and frame structures.

Do-it-yourself penofol mounting works can be done easily without the involvement of specialists, The main thing is to follow safety instructions.

On the floor

Before proceeding to fixing the insulation, it is necessary to prepare the foundation of the floor with a concrete screed. For this purpose, apply a liquid solution of cement, which is poured on the surface and leveled.

Experts do not recommend laying down the foil material immediately, but using foam plastic with a thickness of 7-15 centimeters.

The following actions are associated with the selected type of penofol:

- If you use penofol type A, then fixing glue is applied to the foam with a uniform layer, and then fix the penofol.

- If a type C foil material is used, then the application of glue is not performed. This type of material is already equipped with an adhesive solution on the back of the building material. To prevent the waterproofing adhesive from drying prematurely, it must be covered with polyethylene. Before you start, the plastic film is carefully removed, and then the foil material is decomposed into foam plastic.

The building material is laid in such a way that the foil overlaps the walls (about 5 cm), and the resulting joints are glued with aluminum insulating tape.

Laying insulation need foil side of the floor, ie, inside the premises. This will ensure reliable noise and vapor insulation of the material. Upon completion of laying, the protruding parts of the foil are carefully cut off by means of a mounting blade.

When installing a floor heating system, there are 2 basic types of installation: the use of a log or concrete screed. Lags are used in the event that a wooden floor will be mounted on top of the insulation. In this case, wooden logs are installed along the floor over the heating elements.

Horizontal mounting bars must be controlled by the construction level. Then over the log is mounted wooden coating. Thus, the foil material will heat up and release heat from below to the wood flooring.

The second variation is to mount the system under floor heating under the tile. In this case, the heating special elements are covered with reinforced mesh and poured concrete mix. For this type of installation, it is necessary to use ALP type penofol.

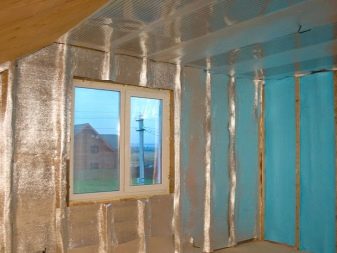

For walls

Foil-type material B is used for insulation of internal walls. Its installation is more complex than other types of penofol, but this insulation material is able to create the most effective thermal insulation of a room.

To improve sound and heat insulation between the wall and insulation make gaps for ventilation.Insulation with one-sided foiling easily glued to the wall or heavy insulation material (foam).

Material with a double-sided metal special coating is mounted as follows:

- Using dowels, you need to fix the bars on the concrete wall (thickness 1-2 cm).

- They are mounted on a layer of penofol type B with screws or mounting brackets.

- A plasterboard product is laid on top of the insulating building material, which is fixed to the rails with self-tapping screws. To leave gaps for ventilation, wooden blocks are installed on top of the insulation material, the thickness of which is similar to the previous rails. Then fix the drywall.

To avoid drafts, the junction of the foil product must be glued with a damper tape. Instead, you can use penofol, which is cut into strips of the required width.

For the ceiling

Thermal insulation of indoor ceilings begins with fixing a thin layer of foiled material on the base coat. Wooden slats are screwed onto the primary insulating layer, which are the framework for the main insulating building material.Above the rails, the main heat-insulating layer is fixed by means of a construction stapler or screws. If it is necessary to install a third layer of insulation, then its installation is carried out similarly to the previous variation.

To create conditions for decorating the building on the last layer of insulation installed drywall. We should not forget to process the joints of the material with silicone adhesive or building tape.

For balconies, loggias

After a careful study of the technology of thermal insulation of ceilings, walls and floors, the implementation of thermal insulation in such rooms as a balcony, will not cause difficulties. In this case, the material should be laid on the rafters, and the fastening should be carried out using staples. The main thing is that the insulation material for the balcony does not have much weight, otherwise an accident may occur.

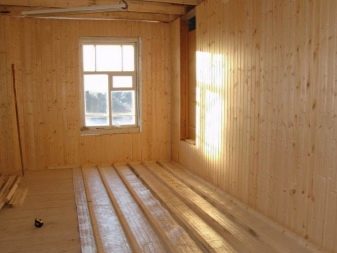

Use in a wooden room

The technology of mounting penofol is no different from other types of insulation. But it is necessary to take into account the fact that the fixation of penofol on wooden surfaces both outside and inside is carried out only in summer, and it is desirable that several hot days pass before starting work.

It is impossible to warm the building if the tree was saturated with moisture and swollen. After installing the insulating layer, the moisture will remain inside, which will lead to rotting of wooden materials.

What to stick?

Properly chosen adhesive solution for the foil material is not yet a guarantee of successful installation. For high-quality compounding of materials, it is necessary that the surface to be glued is carefully prepared. All defects, irregularities, various debris must be eliminated.

To improve adhesion materials from metal, concrete and wood can be treated with a special primer solution.

Concrete floors and walls are leveled, cracks are repaired, and metal products are treated with an anti-corrosion agent.

Adhesive for foiled insulation can be both specialized and universal. You can also use liquid nails, double-sided tape, a thin layer of foam. The choice of glue depends entirely on the purpose of the surface and its further use.

The adhesive must comply with the performance of the insulation material:

- permission to use indoors;

- the toxicity of the solution should be 0;

- high durability of adhesion;

- glue must withstand temperatures in the range of -60 to +100 degrees.

If insulation is performed outside, the adhesive must be resistant to water vapor and liquid.

In order for the penofol to be firmly glued to the surface, the adhesive must be applied to the side that does not have a foil layer. The adhesive solution is applied evenly, without gaps. The edges of the cloth are carefully coated with glue so that during operation the foil material does not peel off.

Before you start fixing penofol, you need to wait 5-60 seconds for the glue to dry slightly. This ensures a better grip. Penofol pressed to the surface, holding, with particular care to smooth.

If the insulation is glued pieces, then the joints are additionally glued.

Reviews

Insulating material Penofol is in great demand among consumers. Due to its high technical characteristics, it has positive reviews.

Due to the fact that the melting point of penofol is much higher than other heaters, this material is used to insulate walls, roofs, as well as insulate the floor from the inside in rooms made of logs (bath, sauna).As a result, high temperatures stay inside for 48 hours.

The use of foil material for thermal insulation of walls inside a brick house allows you to create effective thermal insulation of the room, while the loss of heat energy is not terrible.

The use of foil material for the exterior of the house allows not only to warm the room, but also to protect the building from the aggressive environment.

On how to insulate walls with penofol, see the following video.