Floor Enamels: Classification and Choice Features

The flooring plays a huge role in the interior of the housing, but over time it can lose its original appeal. To update the floors and give them a new life, there are many ways, the most popular of which is painting with enamel. Today, the construction market is represented by a huge assortment of paints, which differ among themselves not only in price, but also in characteristics.

Special features

Enamel, which is used for painting floors, is a suspension consisting of colloxylin, alkyd resin and organic solvents. It is suitable for indoor use and perfectly paints any surface.

The features of the floor enamel include the following points:

- high resistance to temperature changes: withstands temperatures from -12 to +60 С;

- protection from moisture;

- the possibility of polishing and grinding;

- ease of use: the paint dries quickly, is applied in a uniform layer and gives the surface a matte or semi-matte texture;

- a huge selection of colors;

- available transportation.

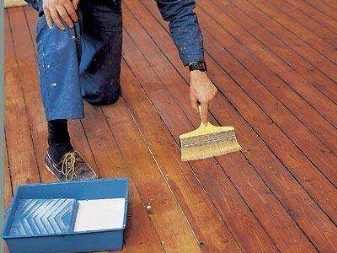

To improve the properties of enamel, the floors before painting must be thoroughly cleaned of dirt., remove scale and dust. If you plan to paint on wooden surfaces, they are pre-polished, primed and dried. In addition, work can be performed only in a well-ventilated area - this will help avoid the accumulation of harmful odor and speed up the drying process.

Kinds

Enamel is made from a variety of fillers, which are combined with colored pigments and varnishes.

Depending on the components that make up the paint, there are mixtures of water and organic base.

In addition, the enamel may differ in structure: it is divided into a primer, hammer, acrylic, nitro enamel, polyurethane and alkyd. For painting flooring most often choose the following types of enamels:

Alkyd

Alkyd It is made from pentaphthalic and alkyd varnishes with the addition of antiseptic and marble chips. This enamel is dissolved by “white spirit”. The coloring agent has high technical characteristics, which include elasticity, water resistance and durability. Alkyd mixtures are also not afraid of temperature fluctuations, they retain their original color for a long time, therefore they are ideal for finishing floors in various rooms.

Polyurethane

Polyurethane. This dye contains many additives and has good adhesion. It can withstand not only low temperature, but also mechanical stress.

Polyurethane enamel, as a rule, is used for painting concrete floors, as well as coatings in garages and warehouses.

Semi-gloss paint is extremely popular. - it protects the floors from abrasion and exposure to chemicals.

Acrylic

Acrylic. It is an odorless universal blend that forms an elastic layer on the surface of the coating, keeping the treated surface from damage.

PF-266 quick-drying enamels deserve special attention - they do not fade in the sun, are moisture resistant and are easily applied to the floor with a brush.

This paint is produced in a different color palette. For flooring in apartments and houses recommended golden-brown enamel PF-226. She originally emphasizes the natural beauty of wood and fills the interior of rooms with a cozy atmosphere.

Manufacturers

Today, the construction market is represented by a chic range of floor enamel, with each manufacturer trying to make its products as high as possible and affordable. Well proven VGT paintwhich is designed for both internal and external works.

It perfectly paints the flooring of wood and concrete, gives them a beautiful texture and shine.

In addition, this type of finishing material is characterized by high resistance to light, water and precipitation.

Positive feedback received and enamel production Lacra. Due to its universal properties and durable adhesion to the surface, paint is widely used in flooring.

It is easy to apply on the base, resistant to water and chemical solutions, does not require additional solvents.

In order to paint a cement, concrete or wooden floor with high quality, it must first be thoroughly cleaned, degreased and covered with an acrylic primer. Finishing can be applied only on dry coatings.

Special attention also deserves enamel production “Prestige” and “Tex”. It is usually chosen for painting wooden floors. Enamel beautifully decorates wood, gives it an unusual texture and relief. In addition, this paint is produced in many shades and dries quickly.

How to choose?

Enamel is considered an ideal coloring agent for flooring, as it allows you to update their appearance and provide the foundation with protection from negative effects and mechanical damage. But in order for the floor to look beautiful at the end of painting, it is important to choose the appropriate type of enamel, which depends on the type of surface.

For a wooden floor most often choose enamels on an acrylic, oil and alkyd basis. The surface of the tree needs good preparation. To do this, it is leveled and covered with a protective primer.

At observance of all technologies of painting such enamels perfectly preserve the structure of natural material and originally transform the interior of a room without requiring large financial expenditures.

The floors of the boards are often painted with oil enamel, as it is inexpensive and well impregnates the array.However, such a composition dries out for a long time and has a sharp odor, so the colorful work should be done in a ventilated room. For rooms in which there is a large crowd of people, it is recommended to choose polyurethane paint, as the floors need protection from scuffing, scratches and damage.

Such enamel does not require renewal for 5 years.

As for acrylic dyes, they do not give the tree a glossy shine and prevent the formation of mold and fungus. This type of enamel is very popular because it has a chic color spectrum and is characterized by high quality. Most often, acrylic blends are used to paint coatings in supermarkets, shopping malls and stores.

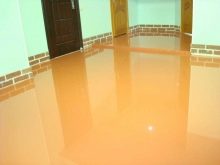

Sometimes in living areas there are concrete floors. They are considered durable, but in order to extend their service life, additional protection against abrasion and moisture is needed. In addition, concrete may crack and be subject to mechanical damage.

To avoid this, the masters recommend for the painting of concrete to acquire epoxy and acrylic enamel.

At the same time, acrylic dye prevails over the epoxy variant, since after its finishing the floor becomes brilliant and beautiful.

Concrete coatings need to be painted in two layers, so this fact needs to be foreseen when purchasing enamel and purchasing it with a small margin. A good dye for concrete will also be an epoxy mixture, as it can withstand temperature changes. However, this material is produced in a small assortment of colors.

What and how to paint a wooden floor, see the following video.