Enamel on metal: choice and application

For painting metal surfaces can use a variety of compositions. But not all of them are equivalent. It is important to choose the most productive in a particular case design solutions. We understand the specifics of the choice of enamel for metal.

Special features

Enamel on metal has one key task: it is to protect the surface from corrosion processes. A similar measure is needed for those items that will be constantly in the open air or exposed to the destructive action of water. At the same time, it is impossible not to mention aesthetics, because coloring compositions for metal products are able to give them an elegant appearance. If the choice of enamel is far from correct, the technology is not followed, the coating looks bad.

The selection of coloring compositions should be based on their chemical nature and intended purpose. Not every coating can be applied to a specific surface. Most paints, for example, are not suitable for galvanized objects, because they have too little adhesion.

The optimal type of dyes, as a rule, is 3 in 1, when, in addition to pigment, there is also a primer for metal and a rust converter. The overall lifespan of such varieties is much longer than that of plain enamel.

Types and characteristics

Enamels and other paint and varnish compositions for metal are represented by three main types:

- oily;

- alkyd;

- acrylic.

Two-component mixtures, dyeing combinations based on polyurethane and other similar improvements are rather classified in the industrial category. They are resistant to corrosive processes and aggressive environments. To use such mixtures, despite their high anticorrosive characteristics, is impractical in domestic conditions: the work is costly and not sufficiently effective.The oil type is cheaper and can be purchased at almost any paint shop.

The problem is that such enamels can not be called quick-drying. Under the action of sunlight, they quickly fade, losing their visual appeal. The effectiveness of protecting metal from rust also leaves much to be desired. Oil painting products are not resistant to heat. For boilers, radiators they can not be used, it is dangerous.

On anticorrosive activity alkyd enamels are better. Buy them now is not difficult. Increased resistance to negative atmospheric effects and temperature changes allows the use of such mixtures when conducting outdoor work. The best choice of the vast majority of practitioners recognizes acrylic paints, which are based on clean water. They are completely safe for the health of painters, do not have an unpleasant smell.

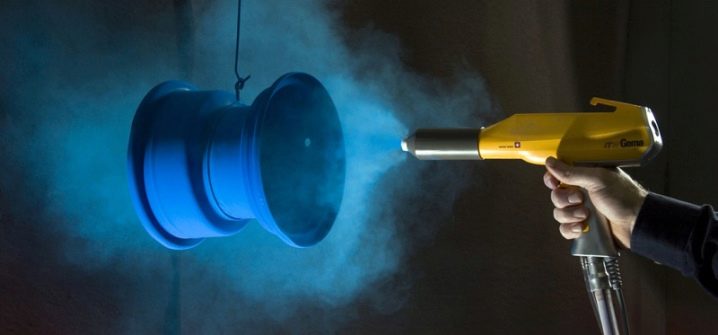

In terms of resistance to strong heat and the negative effects of the external environment, a combination based on acrylic is no worse than alkyd analogues. This allows you to increase the period during which metal objects retain external attractiveness.Quick drying will appeal to professionals and ordinary buyers. Powder coating of metal with all its virtues can not be made at home. The need for a special chamber depreciates the high technical qualities of such a coating and its durability.

Chemical resistant paint is resistant to caustic substances, it must be technologically advanced and practical, does not create problems when applied. Heat-resistant and fire-resistant enamels have nothing in common, they are mutually exclusive concepts. In the first case, the surface should remain unchanged under the action of strong heating, and in the second, on the contrary, it must swell and cover the base from the effects of the flame. In addition to the basic pigment, the two-component mixture has epoxy, corrosion inhibiting substances, and polyurethane. Typical polyester enamel in most cases creates a glossy finish on pre-primed surfaces.

In addition to these varieties, it is customary to distinguish such species:

- dielectric;

- polymeric;

- oil and petrol resistant;

- weatherproof

Their main characteristics are clear from the names themselves.The consumption rate per 1 m2, depending on the chemical composition, the conditions of application and the type of metal being processed, can be 1 kg per 8–10 square meters for interior work and 10–14 square meters. m with external. We are talking about quality compounds that serve for a long time.

Color spectrum

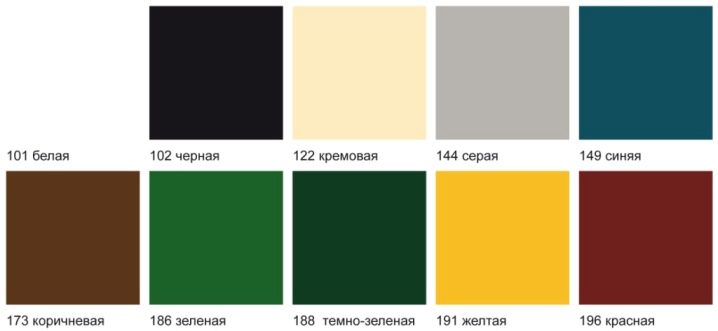

The palette of enamels for metal includes a variety of shades (glossy, semi-gloss, matte). More often buyers are interested in white and yellow tones. It is advisable to paint radiators and other heating parts in white. Yellowish tone looks elegant and noble in almost any conditions, it perfectly covers rust.

The color of artistic enamel is determined by the color of the metal oxide used in production. For example, iron and chromium compounds help create a red tint. Black enamel is obtained by the introduction of oxides of manganese or iridium. The critical stage of technology is considered the firing stage. If you ignore them, the color will be different.

Application area

When carrying out external work, as well as internal, it is required to carefully prepare the surface. Neglect of this requirement may lead to the rapid appearance of rust stains and loss of attractiveness of the appearance of the coating.The color of wood is more complicated than the application of the coloring composition on the surface of metal products: it is porous and absorbs paintwork readily. These coatings are very different in their properties and features.

When choosing a coloring mixture, you need to pay attention to the conditions of its use. For example, those coatings that can be used for painting indoors are completely unsuitable for metal tiles.

Manufacturers

Often, the choice of a particular manufacturer puts an ordinary buyer at a standstill. We note several companies whose products are in demand today. Russian company "Tex»Manufactures high-quality enamel for painting metal structures. Among other companies worth paying attention to the range of companies "Tikkurila", "Hammerite", "Commander". Regardless of the brand you need to study the actual characteristics.

In the next video, see a review of 3-in-1 metal enamel düfa Hammerlack.