Orthopedic bed base

The choice of bed should be taken very seriously. This piece of furniture performs one of the most important functions in any home. High-quality and comfortable model will contribute to a strong and healthy sleep, as well as good rest. The most comfortable and even healthier specimens are with orthopedic bases.

What is it and why?

Not so long ago, in our country, we learned that sleeping on beds with springs is unhealthy, and on a good old feather bed it is simply uncomfortable. After that there was a fashion to sleep on the boards. As a rule, rigid wooden structures were enclosed under the mattress. Many people used ordinary wood doors for this.

Strangely enough, such systems still had some orthopedic effect, but there was no question of a comfortable rest on such a bed. Also, they had not the most attractive appearance. Nowadays, very comfortable and high-quality orthopedic bases have been developed, so hard and outdated options can be abandoned.

Such designs are able to make as comfortable as possible even the usual inexpensive mattresses.

Today, there are several varieties of orthopedic bed bases.

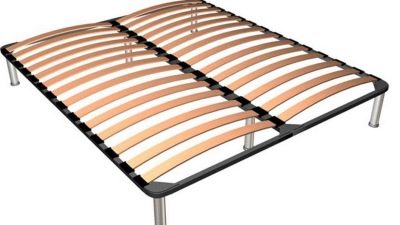

They differ from each other in design and performance, but they have one principle of operation. In all models there is an orthopedic grille. It is made of different materials and complemented by various functional elements.

From the foregoing, it can be concluded that orthopedic foundations primarily perform the important function of supporting sleeping furniture. The mattresses installed on similar designs, double the functions and useful properties.

Design

Orthopedic accessories are installed in the furniture box.As a rule, the frames of these elements are made of metal and are very durable. They can be full bed bases. To do this, the furniture must have legs of different heights.

The main task of the orthopedic base is the correct distribution of the load and the formation of the springy effect of the bed.

Designs may have different characteristics and differ from each other:

- Material rack.

- Indentation between the slats.

- The width of the rails.

- The strength and reliability of the frame, as well as the materials from which it is made.

- The length and width.

- The possibility of changing the degree of elasticity of the basis of the bed.

The latter function is carried out by electric drive or by raising the base.

Different products may have different base designs.

For example, for a model designed for one person (single bed), most often a special grid is provided in which there are 4-5 supports.

There are also designs in which there is no central leg. If the lattice does not have supports, then it is attached directly to the furniture frame with the help of tsarg. These parts are special frames.Slats are installed between the tsargs. It is worth paying attention to the shape of the rails. They should be slightly curved. Such design features are necessary for the load to be distributed evenly along the entire length of the base.

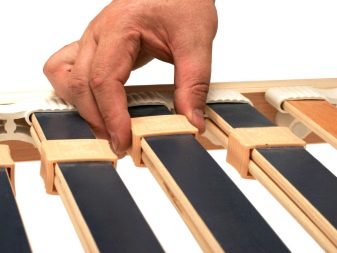

Each individual rail is installed in the holder, in which its ends will be slightly movable. As a rule, these parts are made of durable and flexible wood. They have a springy effect, necessary for orthopedic grounds.

For a more spacious double bed, it is necessary to select the base only after all measurements of the frame and the mattress. The design of such models is significantly different from single instances.

As a rule, in such products there are slats with the same length as in single beds. However, they are located a little differently: in 2 rows. In the lattice for double furniture there is a transverse crossbar. Slats must be attached to it and to the edges of the frame.

The main advantage of such models is that the basics in them can be adjusted at their discretion. In such structures, the possibility of changing the tension of the lamellae is provided.

For example, for people with high weight, high elasticity of the base is ideal, and for lightweight ones - medium or the smallest.

Often beds with orthopedic bases are complemented by lifting structures.

The presence of such parts is appropriate in the event that the base under the mattress is the basis of the lamellae. In this case, a folding mattress and a grid with lamellae will provide the most convenient access to the spacious open niche. It can be used as a roomy storage.

High-quality lamellae made from natural wood are durable. Designs with such elements can serve their owners for more than a decade. As a rule, in really high-quality and reliable bases, the slats change very easily and quickly. If we are talking about a low-quality product, then the replacement of the rails can cause problems.

These thought-out designs will not require special care. However, if you suspect that the system has been violated at some site, then it is worth conducting a thorough inspection. If the slats at the base are out of order, then new ones should be installed instead.

Kinds

Currently, the furniture market is replete with multifunctional and practical furniture, complemented by various mechanisms and thoughtful designs:

Orthopedic beds with a folding mechanism are widespread today. In such instances there is a comfortable base, which is not much different from the classical models. The only difference between folding beds and regular beds is a special mechanism for lifting.

There are several types of arrangements that are available in folding beds.

- The simplest are manual designs (hinged). Similar models differ in durability and wear resistance. They rarely fail. However, these options are not suitable for everyone, as it is rather difficult to arrange them. To raise the bed with such a mechanism, you have to hold the base and mattress on the weight, and these items are not the easiest.

The bed with the manual lifting mechanism is not recommended to be put in a children's bedroom. The child can not cope with such a model and get injured in the process of raising the bed.

- Spring mechanisms are not the most convenient in lifting. Especially often this problem is faced by people who complement the bed with a heavy mattress. In the process of lifting the base is delayed in the “hanging” state due to the resistance of the springs. Such a mechanism is simple and reliable.

The main disadvantage of spring beds is their fragility. Over time, the springs in such a mechanism stretch and lose elasticity. Solve this problem will only complete the replacement of these parts.

- The most modern and high-tech are lifting beds with gas shock absorbers. They unfold quickly and easily. The base and mattress in such models rise smoothly and noiselessly. Such a mechanism is designed for long and regular operation. It withstands heavy loads. Most often gas shock absorbers are present in spacious double beds and are under an orthopedic base with a heavy mattress.

- Recently, lifting mechanisms equipped with electric drives are gaining popularity. In such models, the base and the mattress are raised using the remote control.

Orthopedic lattices are collapsible and welded. Welded varieties are typically installed in entirely metal and wooden models. The device of similar structures in many respects repeats integral options. Collapsible bases are available with and without legs. However, this fact does not affect the functional characteristics of the furniture.

Durable and durable are metal bases.. Such options are less common than wooden foundations. In the production of such parts is used high-quality corrosion-resistant steel. Metallic bases can be painted and they are treated with special polymer coatings. The average service life of such reinforced bases is 25 years. They are inexpensive and do not lose rigidity over time.

Recently, adjustable orthopedic beds are in great demand.

There are 2 types of such structures:

- With regulation of lamella stiffness. Initially, the bending of the rails is designed for an average healthy person. But for people suffering from various diseases associated with the spine, the grounds with such details will not be enough.In a quality regulated basis, you can change the level of rigidity at once of all the lamellae or some of the rails located in a certain area.

- With adjustable position. Beds with a lifting mechanism most often have such an interesting and useful function. In this case, it is used a little differently than in classic models with roomy niches for storing bed linen.

Orthopedic base in such models is divided into segments. Their position relative to each other is easily changed in accordance with the desires of the user. The upper part can be raised for greater comfort of the bed. In such conditions, you can comfortably sit and drink a cup of coffee, read a book or watch TV in the evening.

Also in such beds the lower part changes. This feature is especially useful for people suffering from edema. It is not always worth putting a pillow under your feet for the night. In this position, the feet slightly raise, and the swelling really subsides, but a large load on the knee joints is provoked. You can solve this problem with an orthopedic base,in which the lower part is slightly raised at a slight angle.

A functional combination will cost a little more to the buyer. Such grounds combine all of the above properties. Such furniture can be easily customized.

Base dimensions

High-quality and comfortable bases for small single beds are available with a length and width of 80x190, 80x200, 90x190 and 90x200 cm. Typical bases for a double bed have dimensions of 160x190, 160x200 cm. But there are also larger options. For example, the bases for King Size and Queen Size beds have more impressive dimensions: 180x190, 180x200, 200x200, 200x220 cm.

At present, in many furniture stores there are foundations separate from the beds. The most popular are specimens with a length and width of 140x190, 140x200 cm. Such models are separate interior items, assembled from different elements. These designs are most often bought by people who are in constant traveling. For one and half beds, bases are made with the following parameters: 120x160, 120x190, 120x200 cm.

Materials

The materials from which orthopedic bases are made directly affect the quality of the finished product:

- The most durable and reliable are metal options. They do not deform, do not bend or begin to creak over time. They can be used every day. Metal bases can easily withstand heavy loads without loss of comfort characteristics.

The main disadvantage of such structures is their weight. Metal bases are quite heavy. Because of these elements, the sleeper adds significant weight and ceases to be mobile.

- However, metal options are less common than wooden substrates. It is recommended to choose high-quality and environmentally friendly products from solid wood. The most durable and wear-resistant structures are made of oak, beech or alder. Such constructions are expensive, but they serve for a very long time. They are difficult to break or damage.

- The bases from such inexpensive materials as MDF or a chipboard are less steady and reliable. Lamellae in these structures do not have high strength and durability. They are easy to break. If the slats in the base come into disrepair, they must be replaced with new ones.

Top Rated

Quality and comfortable orthopedic bases produces a large Russian factory "ComCore". In its assortment there are strong models for double, single and single beds, as well as modern designs with electric drive. All systems are equipped with solid metal frames and wooden battens.

The bases with patch and internal fastening of the latoflexes, as well as folding and folding models, are manufactured by the Glazov metalwork factory Forward-Furniture. All designs are available with different lengths and widths, so each buyer will be able to choose for themselves the option of suitable dimensions. Base frames from Forward-Furniture are welded all-metal. Attached to them are bentwood latoflexes with propylene holders.

Orthopedic bases from the Italian manufacturer Lineaflex are in great demand. They are inexpensive and are excellent representatives of the budget class. High-quality constructions are not afraid of temperature changes and atmospheric effects, as they are treated with a special powder.Lineaflex base frames are made of steel pipes, which makes them very strong and durable.

Various variants of the bases are let out by company Vegas. In the assortment of the company there are designs of various sizes: from single to royal copies. Vegas branded bases have eco-friendly birch wood slats and sturdy metal profiles.

Many consumers opt for popular and functional products from the Ormatek brand.. This well-known brand offers a variety of reasons to choose from customers: from orthopedic to solid. Orthopedic options have lifting mechanisms and special transformation systems. The basics from Ormatek can be chosen for any wallet.

How to choose?

Choosing a comfortable and high-quality orthopedic basis, you should consider the following parameters of the bed:

- First of all, it is necessary to take into account the type of mattress. If there is a spring block in it, then it is better to buy a support with a distance between the lamellas of 5 cm. In case you purchased a springless mattress, it is better to choose a base in which there are 3 cm between the slats.

- If you have not bought a mattress, then you should rely on one simple and universal rule: the more often the slats are located, the better. Such bases will withstand heavy loads and will last a very long time.

- The dimensions of the base and the mattress should match each other. An overly large mattress will crawl and hang out of bed. This can adversely affect the comfort characteristics of the bed.

- Experts recommend buying a bed with an orthopedic base, with which the mattress comes with it.

- Do not forget that a comfortable orthopedic base is absolutely not suitable for hard mattresses consisting of coconut coir. This material is not designed even for the slightest troughs.

- You should also decide on the material of the base. Here the choice is small: wood or metal. Most often, people buy bases with metal frames and wooden slats. It is recommended to choose models in which the slats are made of natural wood, as they are more durable.

- Buy orthopedic bases made by popular and well-known brands. Such models will delight you with high quality and long service life.

Recommendations for choosing the base for the bed and the lifting mechanism, you can learn from the video below.