Bed base

The bed is one of the most important pieces of furniture in any home. Such an item should be of the highest quality and comfortable. These characteristics are largely dependent on the frame and bed base.

What is and why?

The convenience of a berth directly depends on a mattress that is correctly chosen. It is placed on the base of the bed. This element plays an important role in the design of furniture, it is necessary for a healthy sleep and good rest.

A quality base of suitable size can prolong the life of the mattress. In addition, this component of the bed helps to evenly distribute the load on the bed. It contributes to the excellent orthopedic effect.

Some varieties of bases provide a high breathability of the mattress.These options are more expensive, but with their help there is high-quality and natural ventilation of the air.

Modern manufacturers produce not only ordinary, but also reinforced bases, designed for use by users with high weight.

Without such parts, the bed can be flushed under various loads, which will lead to the loss of its attractive appearance and deterioration of convenience.

Kinds

There are several varieties of bases. Each option is designed for a specific operation and has a set of characteristics.

Solid

Solid bases (in other words - flat) are beds, consisting of planed boards, cheap plywood or regular sheets of chipboard. As a rule, such parts in the manufacturing process undergo various treatments with special protective and decorative compositions. Such bases are attached to the bed frame.

Solid bases are heavier. They do not allow the mattress to fully reveal the anatomical abilities.

Another disadvantage of such structures is poor ventilation. For this reason, they serve a short time and quickly fail.

Hard baseless base today is no longer very popular. This is a foundation shield. Furniture with such a component is inexpensive, and it is suitable for a variety of types of mattresses.

Most often, beds with hard solid bases are chosen by people who have certain problems with the spine, in which it is necessary to sleep and rest only on a flat and not very soft surface.

Orthopedic

Has a frame made of wood (natural or artificial) or iron lattice anatomical base. Such options can be equipped with a popular lifting mechanism. This could be a sofa bed with a folding bed.

As a rule, such products stand on legs and have lamellae made of wood, which are attached to the base with the help of special lat holder.

Orthopedic designs are among the most popular and sought after. They are distinguished by remarkable air circulation, which makes the beds more hygienic and comfortable.

Lamellae in such models are straight and curved - depending on the shape of the furniture.

Orthopedic mattresses with such bases serve much longer and do not lose theirpositive qualities.

Orthopedic options are usually flexible. Lamellae in them are narrow and wide.

Models with wide slats are ideal for placing mattresses with a dependent spring unit called “bonnel” or for soft springless options.

Large width slats are inexpensive. However, after a long use of such grounds, creaking may occur, especially if the mortise method was used during the installation of the base.

Narrow slats are designed for the use of mattresses with a high density of springs and high-quality soft products. Most often the bases with thin slats are available in more expensive furniture.

Orthopedic bases also occur transforming. Such options are often supplemented by electrical wire. These systems can be controlled using buttons built into furniture or a remote control. The position of the bed is chosen by its owner. You can, for example, lift the headboard.

Adjustable

Regulated bed bases are in great demand today. They have adjustable lamellae, the stiffness of which can be changed with the help of special regulators (or cursors).

Such elements can affect the degree of elasticity of the bed and adjust it for themselves.

In the areas of the base where additional adjustment of stiffness is necessary, double-layer armor is installed with additional cursors attached to each pair.

Collapsible

The folding bases are convenient and simple in operation.

The main advantage of bedroom furniture with such a component is its mobility. The folding base can be easily moved to a new place and even transported a considerable distance in the car. Often, owners of country houses and country houses turn to such options. Such models are also equipped with lamellae and have an excellent orthopedic effect.

Not separable

At the present time, many firms offer customers high-quality soaring beds. Such interesting furniture creates an amazing effect, as if it flies above the floor surface. As a rule, such products have non-separable static bases. Often, this bedroom furniture is complemented by beautiful lighting in the lower part.

Frameless

Not very expensive frameless base.As a rule, such products are flexible and are most often found in small single beds. In another way they are called liners. Such constructions are laid out along longitudinal bars, which are located in the inner part of the bed and are fixed with the help of ordinary screws.

Bed bases vary not only in hardness, but also in shape.. Classic are rectangular designs. There are pieces of furniture that have a rounded, oval or curved base. Common are models with linen drawers at the bottom, as well as concise options without a headboard.

Materials

Today, many consumers prefer furniture equipped with a wooden base. The choice of such elements is due to their durability and environmental friendliness.

- Quality and reliable parts are made from natural wood. Most often in the manufacture of such products used birch, pine, oak, beech or alder. Sleeping furniture with a base of natural wood is expensive, but its performance characteristics fully justify the price.

- The cheaper are the basics plywood, MDF or chipboard. They are less durable, durable and reliable than natural options. LDSP is completely dangerous to health. Such material is created from wood chips and other waste wood production.

All components are bonded to each other using harmful formaldehyde resins, which under certain conditions can release hazardous substances.

- Springy effect is different plastic constructions. Such systems are often supplemented by adjustable beds, control takes place using the remote control. The service life of such a design on average is 10-15 years. These products are durable and easy to use.

- The most durable are metal rack or solid. The service life of such systems may exceed 25 years. Such structures are inexpensive and have good orthopedic properties. Not the most reliable mesh options. Similar bases are equipped with both beds and folding sofas.

Mesh metal structures do not withstand heavy loads and over time sags.This leads to the loss of the attractive appearance of the furniture and its convenience.

Dimensions

The bed bases can have different sizes:

- for single models: 80 × 200, 90 × 190, 90 × 200, 90 × 210, 80 × 190 cm;

- for the semi-double: 120 × 200, 120 × 190, 120 × 160 cm;

- for the doubles: 140 × 200, 140 × 190, 140 × 200, 150 × 200, 158 × 205, 160 × 190, 160 × 200, 160 × 220, 180 × 200, 200 × 200, 220 × 200 cm.

For beds of non-standard sizes, the same non-standard bases are made. For example, it may be a model in which the width of a berth is 159 cm.

Which base is better to choose under the mattress?

From the base of the bed depends on the level of comfort of the bed. To date, the most high-quality and convenient are the rack construction with wooden lamellae, located at a certain distance from each other.

This foundation is orthopedic, so rest and sleep on it is a great pleasure.

More durable and reliable are the bases in which the slats are located at close distances from each other. Such structures are reinforced and easily withstand heavy loads. They are ideal for obese people whose weight reaches 100 kg or more.

More affordable are hard, straight reasons.Being on such a surface, the mattress will not be provided with high-quality and natural ventilation (as in the case of plastic structures), which will adversely affect its hygienic characteristics and shorten its service life.

Over time, the mattress can be deformed and washed out on a metal mesh base. It is not designed for long life and quickly loses its elasticity.

Rack metal structures are more reliable and durable. They have an excellent orthopedic effect.

How to insert lamellae?

Lamellae are attached to the base of the bed with a special tip holder. These items are made from polypropylene, plastic or rubber.

These holders are attached to furniture with a small bracket that is pre-attached to the frame.

Slats can be installed using special supports made of metal. Reiki are simply inserted into these parts.

In modern models of beds you can find frames with pre-prepared holes for mounting holders.

The choice of mounting for lamellae depends on the furniture body.

How to do it yourself?

Furniture base can be assembled by yourself. For this you need to stock up the following devices:

- bars;

- laminated and ground chipboard profiles;

- MDF profiles;

- shkantikami;

- confirmatist;

- eccentric tie;

- self-tapping screws;

- caps;

- special edges for furniture;

- PVA glue.

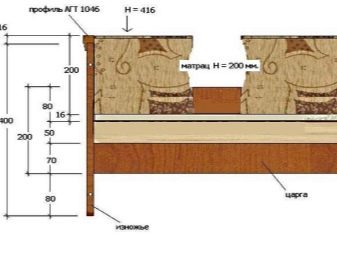

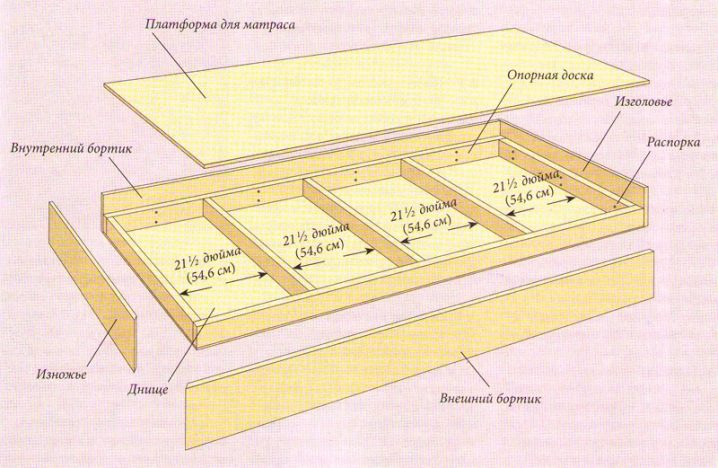

For the manufacture of supports for the mattress ideal for timber from pine with a cross section of 50 × 50 mm. Not to do also without laminated chipboard. Decorative items should be made of MDF.

The bar is useful for strengthening the base. It must perform the function of support and the basis of the whole structure. It is best to purchase a pair of bars with a length of 4.5 m. You do not need to expose wood for additional processing, since the bed base will not be located in a prominent place.

When buying a timber, it is necessary to pay attention to the conditions in which it was previously stored.

It is not recommended to buy material that was contained without additional canopies or gaskets. As a rule, such bars are distinguished by high humidity, an unpleasant color and often have various defects or deformations on their surface.

The head of the base must be made of MDF and chipboard. The texture of the part should be directed from top to bottom. The bottom edge of the headboard must be milled to make it look more neat. This element is attached to the main beam with holders and fixed racks on the side parts.

The main details of the base are the backs and backs.

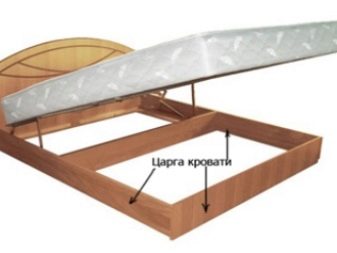

Tsargi are longitudinal parts located at the base of the bedroom furniture. They are made using the initial preparation of the assembly holes. After these actions you should fix the bars of the base with screws and glue.

After preparing all the necessary parts, you can proceed to the assembly of the bed. It is recommended to do this in the place where you plan to install the resulting product.

After that, you need to put the central timber together with the supports and install the support necessary for the mattress.

It is necessary to carry out the attachment of supports to the timber. To do this, you can use conventional screws. Before this, the bars should be attached to the holders, which at the very beginning should be attached to the backs.

After all the above actions, you can proceed to the final stage of manufacturing the bed base: installing the base for the mattress. This item can be made of laminated chipboard.It should consist of two halves, since such structures are much easier to assemble.

The bases are made much easier and faster from ordinary pallets. Similar pieces of furniture look very original in many interiors and are not bad alternatives to ordinary beds.

For the manufacture of such products is recommended to use more durable and durable euro pallets.

First you need to purchase 6-12 pallets and sand them carefully, since such materials often have notches and splinters on their surface. It is also recommended to carry out the processing of pallets with special antiseptic agents.

After that, the pallets must be put on the floor and fastened to each other using self-tapping screws.

Mattresses in such furniture are stacked on a simple and rigid basis. Some users add pre-purchased bases with lamellas to such home-made furniture.

Reviews

Modern buyers are trying to choose not only beautiful, spectacular, but also the most comfortable furniture for the bedroom.

Many people note the fragility of metal mesh bases.At first it is very convenient to sleep on them, but over time they are pressed through, and instead of them you have to buy other products.

Many buyers prefer robust wooden lamella designs. People note the excellent characteristics of such orthopedic grounds.

Many people with diseases of the spine are satisfied with the purchased beds with solid solid bases. However, do not rush to purchase such furniture. To begin with, it is recommended to consult with your doctor, as beds with similar basics can harm health.

If you want to buy a modern bed, then you should look at the adjustable models with electric. Buyers who decided on such an acquisition were satisfied, because the base in such products can be fixed in any convenient position. This plus attracts many.

Choosing a bed, read consumer reviews, get expert opinions. So you can compare several optimal options and choose a model that will suit even in small things. High-quality product will delight you as long as possible.

See the next video on how to make the base for a bed.