Diamond cold welding: types and their characteristics

Glues, which are called “cold welding”, are well known and used both in Russia and around the world. One of the representatives of the compositions of this type is cold welding "Diamond". Due to the positive reviews about its quality, glue has gained popularity and is often used in construction and finishing works.

Properties

Glue "Diamond" is unique in its properties, its use does not create any special problems. A nice bonus is the adequate price of the product. The range of applications is quite extensive - the tool can be used for a variety of jobs: from repairing water pipes to gluing car parts.

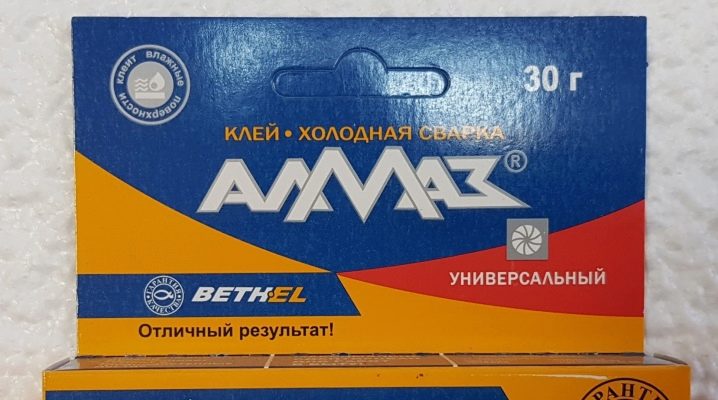

The adhesive is packaged in plastic cylinders and pre-wrapped in cellophane.It is white, but inside it has a gray core, which initially does not mix with the base.

The white base is sufficiently adhesive and may partially remain on the hands when working. This is bad for the basic properties of the composition. To correct the situation, before using the glue you need to wet your hands in cold water.

Cold welding of this brand is packaged in cylinders of various sizes, which is convenient for consumers. To use, you need to prepare only the required amount of material, since its surplus will harden after some time, and it will be impossible to apply them. Therefore, it is recommended not to use the whole mixture at the same time, but in parts.

Before you mix the glue, you need to make sure it is soft. It is also convenient to cut. However, after the material is mixed, it becomes solid.

Composition

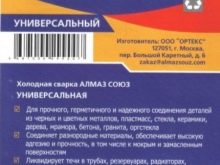

Diamond cold welding consists of a hardener and epoxy resin. To them are added two types of fillers - mineral and metal.

The main advantages of the material:

- due to its versatility, this adhesive can be used in a wide area of work;

- This type of cold welding does not create problems in use, the application does not require specific skills;

- work does not require any specific tools, you can handle with the help of available tools;

- packing in packaging of different volume makes the purchase of welding convenient for the consumer;

- is in a low price category;

- welding is easy to store, it is quite unpretentious and does not require specific conditions.

The main disadvantages of the material:

- when the composition dries or is already dry, it is easy enough to break because of its fragility;

- it is used mostly in everyday life, as it does not withstand serious loads and mechanical stress;

- If lumps appear inside the composition during application, this will adversely affect the quality of the product;

- material may adhere to a dry surface;

- relatively short lifespan, especially with adverse effects.

Where applicable

In cases where objects cannot be glued together with other compounds, it is recommended to use “Almaz” cold welding. In the case when a broken piece of ceramic is badly damaged or a small part is lost, glue can be used to restore it. A figure is molded out of it, or the hole is filled with material, and after solidification, the area becomes dense, and the parts are securely fastened.

This mixture can glue not only homogeneous materials, but also various in its texture. To do this, it is necessary to thoroughly clean the surfaces from dirt and dust and then degrease them.

The only caveat is that the recovered items will not withstand serious loads and strong mechanical stress. Cold welding “Diamond Universal” with a volume of 58 g at normal temperatures is used, it is recommended to exclude their strong drops.

Kinds

Cold welding "Diamond" may vary in volume and composition. In composition, it is divided into several types.

All-purpose adhesive "Union" it can be applied in works of a different orientation. The type of surface does not matter; it is used with both homogeneous and dissimilar materials.

When repairing furniture and woodworking, cold welding is used for woodworking. It helps to eliminate delamination, as well as connects the coatings themselves.

In car repairs, a special type of glue is also used. With it you can glue the details of a small size, get rid of the chips on the body of the machine. Also used for thread restoration.

When working with metal objects, it is recommended to use “Almaz” cold welding, in which there is a steel filler. Can combine non-ferrous metal and other types of metal.

Glue for plumbing - moisture and heat resistant. When using it, tightness is achieved. It is applied during the work with pipes and other sanitary connections.

Key points at work

The maximum working temperature when using cold welding "Diamond" is +145 degrees. The composition hardens over a period of about 20 minutes, but it takes about a day for it to fully solidify. Apply glue is recommended at +5 degrees.

Before using the composition must prepare the surface. It must be cleaned of dust and dirt and then degreased.

The composition itself must be used in the correct proportions. The volume of the outer part should be equal to the volume of the core. Glue mixes up to a soft uniform consistence, after that it is possible to work with it.

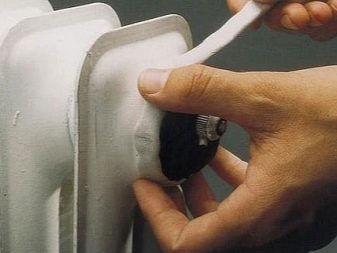

If the surfaces treated with the composition are wet, when applying the adhesive, it should be smoothed for better adhesion to the material. After that for 20 minutes it is necessary to impose a plait.If you want to speed up the drying process, you can use a regular hairdryer. When heated, the composition hardens much faster.

The room in which the work is carried out, it is necessary to ventilate. Use of gloves will not be out of place.

Instructions for use

The use of the composition should be carried out according to the instructions, in compliance with all requirements, then the work performed will please a long period of time. Summarizing, we can distinguish several stages of work with cold welding "Diamond".

It is necessary to begin the process with surface preparation. It is cleaned of dust and other contaminants and thoroughly degreased.

After that, the glue is kneaded. It is necessary to pay special attention to an equal volume of external and internal parts of the composition. Since the glue dries quickly enough, it is best to use a small amount of work.

The glue is thoroughly mixed and kneaded. It should become soft and resemble plasticine in consistency. After that, the necessary figures are molded out of it, or the composition is applied to one of the glued surfaces.

Complete drying of cold welding "Diamond" is approximately one day.After that, the processed item is completely ready for use.

About testing cold welding "Diamond" see below.