Ceramic mosaic: a variety of choices

Interior decoration of the dwelling is a laborious, laborious and costly process. Its result depends on the correct choice of finishing materials and the quality of the cladding. Among the variety of options you can easily choose everything you need to create any interior. One of the most spectacular finishing materials is ceramic mosaic.

Distinctive characteristics

Ceramic mosaic is a popular material used for interior decoration of various rooms.

There are several main characteristics of products of this type:

- For the manufacture of mosaic tiles manufacturers use types of ceramics with different levels of moisture resistance. It is worth paying attention to when choosing products that will often come into contact with water.

- Also, the tile may have a different coefficient of wear resistance.When choosing a tiled material to create a floor covering you need to choose tiles with high resistance to abrasion. For interior walls fit tile made of any tile.

- For facing surfaces of open areas, mansards, one more important property of the material must be taken into account - resistance to low air temperatures.

- When choosing a mosaic for facing a floor covering, an important factor is slipperiness. In this case, preference should be given to a special matte or satinated tile. It should be noted that the use of modern grouting with anti-slip properties when facing the flooring minimizes this not very pleasant feature.

- There are many variants of mosaic designs on the market. It can be a monochromatic tile of various colors, items with patterns, translucent elements or glitter variants. The surface of a mosaic tile can be completely different: smooth, matte, glossy, embossed, with stains, patches and so on. When choosing a mosaic design, you should focus on the type of room and surface, personal taste and features of the interior.

- The small size of the mosaic tile allows you to make the lining not only a flat surface, but also curved. This is especially true of products on the grid.

Advantages and disadvantages

The high popularity of the mosaic is due the presence of a large number of positive characteristics of the material:

- This type of facing material is characterized by high strength, resistance to mechanical stress. Such coverage will delight you for more than one year, without losing its qualities and initial appearance.

- Facing is resistant to high humidity. Excellent technical characteristics allow the use of ceramic mosaics for facing bathrooms, saunas and other similar rooms.

- Ceramic mosaic is ideal for exterior decoration of stoves and fireplaces, as it perfectly withstands high temperatures.

- It is quite easy to care for such facing. Small dirt is removed with a regular wet sponge. When handling severe contaminants with chemicals, the material does not lose its original external data.

- Universal and practical mosaic is used for interior decoration of various premises.A variety of shades (green, blue, red and other colors) and textures in conjunction with the imagination of the master guarantee a modern, original coating of any surfaces. The tile can have a round, triangular, square or long elongated shape. It can be a ready-made composition on a soft basis or independent elements, opening wide opportunities for design.

- For the production of ceramic mosaic used environmentally friendly materials. Facing does not emit toxic substances, so it can be safely used even for the decoration of bedrooms and children's rooms.

However, it is worth noting some negative points:

- Some types of mosaic are of high cost (depending on the material and manufacturer).

- Facing the surface with a ceramic mosaic is a rather complicated and time-consuming process. This is due to the presence of numerous small elements that make up the final floor. It is necessary to possess certain knowledge, skills and experience. Before you start facing work, you need to carefully study the features of the laying process.If you have doubts in your abilities, it is better to seek help from specialists. The services of qualified surface cladding masters are quite expensive, but at the same time you will receive a quality result.

Styling methods

There are several ways to create a mosaic.

- Single color facingIt looks very good. For this method of finishing, you can use both regular smooth tiles and embossed products.

- "Mix" - option at which use a tile of several shades. These can be contrasting colors or similar shades harmoniously combined with each other. You can also use matte and glossy tiles at the same time.

- "Gradient" - very effective method of decoration. The tile keeps within so that color smoothly changed from one edge of a surface to another. You can use a tile of several close colors with the same surface. Matte and glossy tiles can not be combined here.

- Creating a specific image requires special skill, imagination, strength and patience of the master. In the process of such facing, real works of art are created.

Manufacturing features

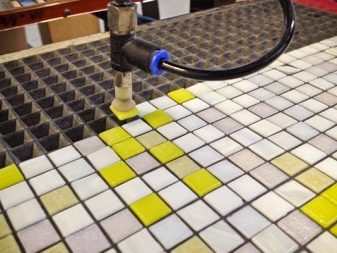

Production of ceramic mosaic is carried out in the same way as the manufacture of ceramic tiles. A distinctive feature is only the size of the finished products.

At the first stage of the mosaic production process, raw materials are prepared. All necessary components are crushed and mixed. Then the raw material is dried and pressed under a certain pressure in the molds. After this, the workpiece is again thoroughly dried. If the product needs to be burned only once, glaze is applied before firing. Then the workpiece is calcined in a furnace at a high temperature. The product of double roasting is processed at low temperatures.

Favorites among manufacturers of ceramic mosaic are Italian and Spanish companies.

It is also necessary to mention the manufacturers of Germany and Russia, which in recent years has enjoyed considerable popularity among consumers.

Piling

Required materials and tools

Laying a mosaic is a time consuming and complex process. The main requirement is the quality of the adhesive composition, because often the mosaic combines individual fragments of different shapes,and all elements are held on the surface only with glue.

The method of laying the mosaic depends entirely on its type:

- Art mosaic. This method of laying material allows the use of tiles of different shapes and bat ceramics. Parts are stacked one by one on strong glue. With this method of laying masters create beautiful artistic images and murals.

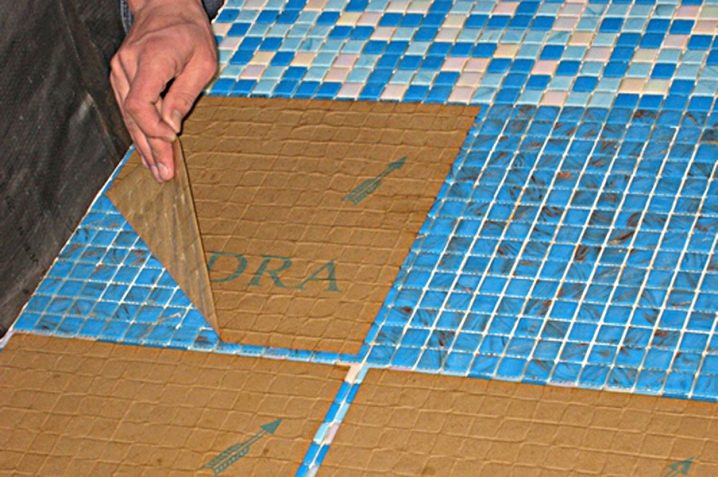

- Ready block on the polymer mesh. The master lays out the individual parts of the mosaic on a polymer grid and fixes them with glue, creating a fragment of the image. Then the resulting element is glued to the surface along with the grid.

- Block on paper. Mosaic fragments are collected and glued face down onto paper. Then the finished composition is fixed on the surface. Products made on paper are small and are mainly used for finishing surfaces with curved lines.

You can make a block on paper with your own hands. Glue must be used special, with certain technical characteristics. Skilled craftsmen use silicone, two-component polyurethane composition. Special grouting is also required for seams.It should not stand out from the background of the tile, so when choosing, you should pay attention to the color of the product. To do the job you need a minimum of tools - several different spatulas.

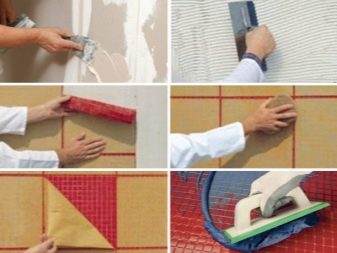

Surface preparation

When facing a surface with a ceramic mosaic, increased demands are placed not only on the quality of the adhesive, but also on the condition of the surface. It should be completely flat. Absolutely not welcome height differences, cracks and chips. At the same time, the surface should not be perfectly smooth either. For better adhesion with the tile, it should be rough. Therefore, after processing the grinder is necessary to use sandblasting. Then the surface is thoroughly cleaned from dirt and degreased. Only after that a layer of special primer is applied.

Installation of finished modules

After careful preparation of the surface it is necessary to apply the markup. Then you need to prepare a small amount of glue. It is not advisable to prepare a large portion of glue, as it dries quickly. The adhesive composition is applied to a small surface with a smooth trowel and leveled with a serrated tool.Then the finished module on the grid or on paper is pressed to the prepared surface and ironed with a rubber spatula. This is necessary to evenly distribute the adhesive under the module.

When working on cladding using ready-made modules, you need to remember and observe two important points:

- The finished unit, made on the grid, is laid on the glue so that the mesh base is hidden in the solution.

- A product made on paper is glued to the outside with a paper base.

In the process of facing you need to ensure that the seams between the modules coincide in width with gaps between the tiles.

This is necessary so that the finish looks homogeneous. After the installation of the modules, the surface is dried. After three days, the paper is removed with a clean, damp cloth. Remnants of glue from the surface are removed with a piece of cotton wool or a rag moistened in an alcohol solution. After that, the seams are treated with a special grout, using a rubber spatula. Excess grout from the mosaic is also removed with a clean, damp cloth or sponge. Then the mosaic is carefully polished.

Observing all the nuances of work, you can create a unique interior. And if you want to show all your imagination, you can create an original mosaic with your own hands, using battered ceramics. Stylish, elegant multi-colored or one-colored mosaic, made by yourself, will be an excellent budget option for facing any room.

How to properly lay mosaic on the grid, see in the video below.