How to glue glass wallpaper?

Today, the construction market offers a variety of finishing materials. Most often, wallpaper is used to clean up wall surfaces. Of the many options presented, the most progressive and environmentally friendly finishing material is glass wall covering, used to decorate not only the walls, but also the ceiling.

Special features

Before you decide on the choice of glass, you first need to understand the composition of this material and its features.

What is it - glass fiber? In the title itself is the answer to this question. The composition of this finishing material contains the same components that are used for the production of glass. Quartz sand, limestone and dolomite mineral are the basis of this finishingmaterial.

During processing, these components are mixed and subjected to heating to a temperature of 1200C. The resulting mass of melting has a liquid consistency, from which it creates the future basis of wallpaper, consisting of thin and light threads. It is from them that the fiber is woven with the help of special machines.

Glass cloth wallpapers are environmentally friendly materials.therefore, they can be glued in any premises. Their fire safety and high service life (10-30 years) makes them an incredibly popular finishing material today.

In addition, the surface of glass fiber can be used for painting without damaging the structure, which is incredibly convenient if you suddenly wanted to change the interior without global changes.

Due to the incredible strength, the color of the surface can change at least 5, and for some brands even 20 times (it depends on the quality of the material itself).

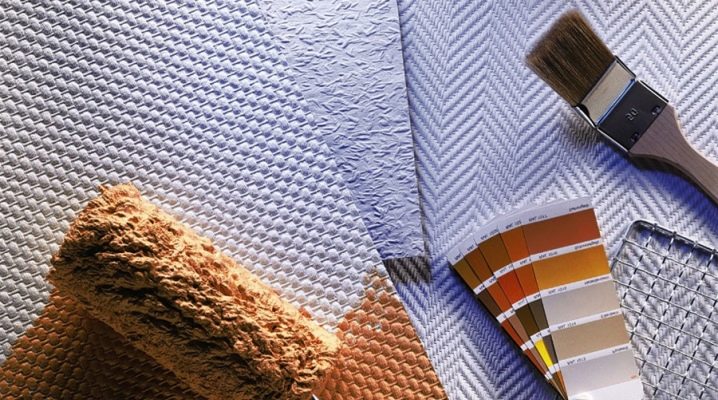

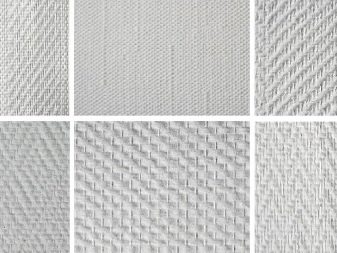

Due to the special production technology, wallpapers are produced with different textures that affect the purpose of the material.

- Wallpapers with a smooth coating perform auxiliary functions: sealing the surface before lining with other finishing materials, hiding the flaws of walls and ceilings, leveling the base before final finishing.

- Wallpaper with a relief structure designed for the main interior decoration.

The thickness of the yarns and variations of the weave affect the final pattern of the wallpaper. Simple drawings in the form of rhombuses, Christmas trees, matting and checkerboard cells are created on ordinary machines. For complex, textured patterns using specialized equipment - jacquard looms.

How to calculate the flow?

Before you buy this finishing material, you must calculate the required amount of wallpaper.

The production form of glass wall is a roll. In order to correctly calculate the flow, it is necessary to know the width and length of the roll, as well as the area of the glued surface. Today, manufacturers produce a variety of rolls in width and length. The most common width in glass wall covering is 1 m, less often there are specimens 0.5 m wide and 2 m wide. The web rolled into a roll can have a length of both 25 m and 50 m.

To calculate the amount of consumables for pasting walls, you first need to measure the perimeter of the room, eliminating the width of the window and door in order to save. But there is an opinion that it is better to include these values in the expense for the stock.

To calculate the required number of webs, it is necessary to divide the perimeter by the width of the roll; the result is rounded, as a rule, in a larger direction.

Then you need to find out by how many panels the roll is divided. For this calculation, you need to know the height of the ceiling, to which you need to add 5-10 cm for convenience. We divide the length of the canvas in a roll by the height with a small additive and get the desired number of webs.

In addition to calculating the required number of cullets, you need to know their density per 1 m2. Manufacturers produce products with different indicators, as a rule, high-quality specimens have a density of at least 100 g per 1 m2, but there are more dense products, where the figure reaches 200 g per 1 m2.

This value affects the purpose of glass fiber. For pasting ceiling surfaces, most often less dense specimens are selected. For wallpapers intended for painting, the density value affects the change in color: the lower it is, the fewer times it will be possible to repaint the surface.

How to prepare different surfaces?

Any repair work does not take place without surface preparation, and pasting walls or the ceiling is no exception.Preparatory work is always carried out taking into account the peculiarities of the base, but regardless of the origin of the material, there is a single rule - this is the dismantling of old coatings that hang poorly on the wall or ceiling.

- If you need to remove the paper wallpaperthey are moistened with water and removed from the surface with a spatula.

- The choice of paint removal method depends on its type. There is enough water and a sponge to remove water-based paint; it is easily washed off. And to clean the oil, acrylic or alkyd paint is somewhat more difficult, you have to use either sandpaper, or, with a small surface area, clean it with abrasive electric tools. But there is also an easier way of cleaning, which is a great time saver, is the use of special washes. It is not necessary to remove the entire layer of paint, if it is well adhered, it is enough to give the surface a rough appearance, which ensures good adhesion of the glass tile in the future.

- For surfaces treated with whitewash, the course of the preparatory work can be carried out in two directions. If lime keeps well on the ceiling, it is applied in one layer and does not leave marks when rubbed, then complete removal of the coating is not required.But most often the whitewashed surface has a thick layer of lime and frostbitten areas, so the coating will have to be removed with a spatula and water with a sponge.

- Ceramic tiled surface will have to completely clean out. It is not recommended to glue this type of wallpaper on the tile. Although theoretically this is possible, there is a high probability that glass wall paper can peel off from such a surface, especially at high humidity of the room. For good adhesion of wallpaper to the surface of the tile must be repulsed.

- Any ground surface, whether walls or ceiling, PWhen mold is detected, it must be specially treated.. For this stage of work, various fungicidal compositions are used, which can be selected at any hardware store.

The direction of the preparatory work for pasting wallpaper depends on the type of surface. Ceilings and walls can be made of different materials: concrete, brick, drywall, OSB plate, plywood. If you wish, you can even glue the wallpaper with the stove, properly preparing the surface, because any of their appearance can withstand considerable heat without losing its functions.

- For concrete and plastered surfaces no special preparatory work is required, it’s just enough to level the distortions with the help of a putty and prime it.

- Plywood and drywall will have to prepare for wallpapering. This is especially true of the joints between the sheets and protruding caps screws. Gypsum plasterboard surface necessarily putty, otherwise there is a risk when changing wallpaper to tear them along with the base material. Then a primer is made.

- For slabs OSB preparatory activities are also required. The joints between the plates are leveled using the serpyanka, and then putty. For better adhesion of wallpaper with OSB slabs, primer and putty are produced if there are large chips. The final stage of the preparation of this material is finishing priming.

How to determine the front side?

Fiberglass wallpaper, as well as other types of coatings, have a front and back side. In ordinary wallpaper, the front side is on top, and in glass wallpaper, the opposite is true: the top of the roll is on the wrong side, and the front side is hidden inside.

In order not to get confused with the sides when cutting cloths, manufacturers mark the wrong side with a line. The color line is blue or gray.

What is primed?

Priming surfaces is the final stage of preparatory work. Do not neglect it, because the quality of the produced primer will ensure reliable adhesion of the glass wall to the surface.

Ideally, if the putty and primer are purchased the same brand, their compositions, as a rule, are perfectly combined with each other.

As a primer, you can use different tools, the benefit today, manufacturers produce special formulations that are selected based on the location of the preparatory work. When wallpapering, suitable compositions are suitable for internal use.

PVA glue is also suitable for priming the surface, the main thing is to properly dilute it. The optimal proportion is 1:10. The priming process must be performed twice. First, apply the first layer of primer, after which you need to wait a certain time to completely dry the surface and apply the second layer.

Glueing process

Step-by-step instructions for gluing glass wall coverings do not differ much from the lining of ordinary types, but there is one significant difference: the glue is applied not to the wrong side of the canvas, as in ordinary wallpaper, but to the surface to be glued.

The adhesive composition should be distributed over the surface of the walls or ceiling evenly, otherwise in places with an insufficient amount of glue small swellings may form, and if there is an excess amount, dents will appear.

- The process of gluing itself begins with the cutting of cloths. required length. It is necessary to work with them carefully, using gloves to protect the skin of the hands, as the canvas is slightly pricked. After painting, this effect disappears.

- The first canvas to glue as smooth as possible, using a plumb for this purpose. In order not to form air spaces under the canvases, the smoothing should be carried out from the central part to the edges of the canvas using a spatula or other suitable means. The excess parts of the blade are cut off with a stationery knife and a ruler (spatula).

- Paste the second and subsequent canvases will be easier.if the first sheet lay strictly vertically (for the wall). It is necessary to arrange the subsequent bands end-to-end while combining the pattern. It is worth remembering that it is impossible to smooth the joints with a roller, there is a risk of damaging the pattern. In the corners, glueing the sheets is a little more difficult than in a straight line, but if you follow certain rules, you can easily cope with this task.

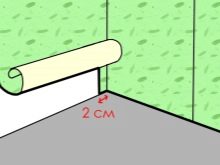

- Tape the inside corner must be neatly, the canvas from one wall to another leads no more than 2 cm, and the excess is cut. The next canvas overlaps. But you can retreat and 4 cm, stick the next strip in the same way and, stepping back 2 cm, cut off the excess.

- To finish the outer corner of the canvas you need to start on the other side by 8-10 cm. The next strip is glued to the surface with an overlap in compliance with the pattern. The gap should be no more than 3 cm. Surplus from both strips are cut off, and the joint under the canvases is coated with an adhesive.

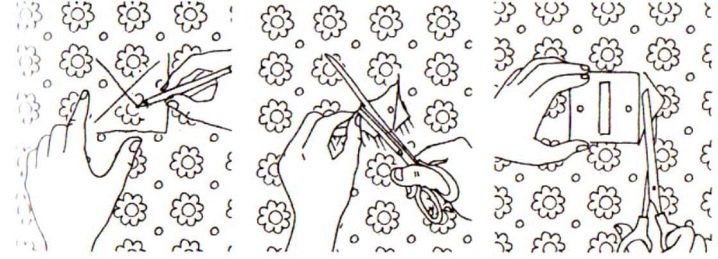

- In order to glue places with located switches and sockets, Regardless of the room in which the repair is going, it is necessary to take precautions: turn off the power supply for the duration of the work and remove the external parts of these devices. Wallpapering these places should be like this: the canvas is cut with a cross, its surplus is removed, the edges of the surface are coated and the strip itself is pressed tightly.

Dry wallpaper about two days. For high-quality drying of fabrics, it is necessary to maintain an optimum temperature (18-24 ° C) and humidity (70-75%).

Painting

For painting the surface with this finishing material are best suited compositions with a base on the water, it is water-based and water-dispersion paints.In addition, you can buy paints, specially designed for glass fiber.

- Before applying the first layer, it is necessary to prepare the surface, namely - apply a primer. As a primer, you can use the composition prepared for painting, but you will need to dilute 1: 1. This approach will help reduce the consumption of the main dye and prepare the surface for the main coloring as well as possible.

- Apply the first layer only after the wallpaper has completely dried. The second layer of the composition is applied after 15-20 hours, it is exactly the time required for the coating to dry.

- For an even application of the layer, it is most convenient to use a roller with a long handle.

Beautiful examples in the interior

Glass fiber for a number of reasons belong to the unique finishing materials. They look equally great in any room and on any surface.

Their resistance to temperature and humidity changes allows you to use this finishing material in the bathroom. Partial or complete decoration of the walls of the toilet looks no less attractive than tiling. Glass fiber is not far behind the tile and in practicality: they can be washed, and if desired, repainted at all.

Pasting the ceiling or walls in a living room makes it easy to choose furniture of different styles, because the embossed pattern on the surface of the wallpaper is concise, and you can choose the color for any interior.

Not every material is suitable for pasting window slopes, and glass cloth wallpaper is not only very practical, but also an element of decor that has a special impact on the interior of the room as a whole.

For more information about glass fiber, see the video below.