How to choose a film on the window?

The modern market offers the buyer a lot of opportunities to create comfortable living conditions. One of them is the film on the windows. This material has its own characteristics and classification. Their knowledge will allow to pick up the film correctly, if the need arises.

Special features

The film on the window is a special material based on polymers. In most cases, it has an adhesive backing that provides a high level of adhesion to the glass surface. Depending on the variety, such a coating is capable of reflecting and absorbing up to 90% of solar radiation. In this case, the material can contribute to obtaining an optimal indoor climate. It protects the room from solar radiation.

The main component in the production of the film is polyester. It is a non-toxic and refractory material that helps to increase the strength and elastic characteristics of the film coating. Due to the elasticity of the film is not torn when attached to the base.

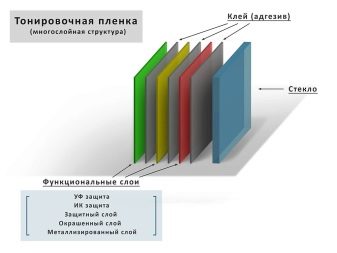

The structure of the material is such that it retains heat when necessary. The range of solar energy has a different impact on the human body. For this reason, the types of film are different. They transmit different rays and in different volumes, delaying the harmful radiation. Even a multi-layer composite structure is capable of transmitting visible light, while delaying, for example, UV or infrared rays.

Usually the film consists of several thin layers. Due to this, the amount of solar energy from the outside practically does not lose optical visibility. However, a slight distortion of the light level is still there. Depending on the modification, the coating may have a colored layer, covered with a laminating film on top. The upper metallized fine layer slows down the burnout of the material under the action of the sun.

Other types are made on the basis of a metallized polyethylene terephthalate with a coating. They are able to reflect microwave radiation.In addition to balancing the optimum indoor temperature, such coatings help protect furniture against burnout when it hits the sun's rays. This is a unique and low-cost alternative to tinted windows, a functional material with decorative features.

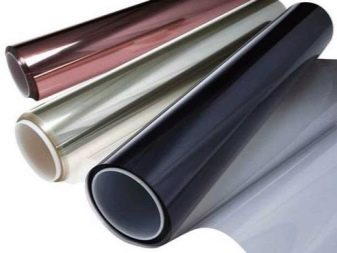

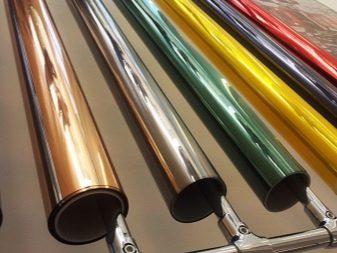

Each layer of several microns, in addition to metallic spraying, may have a ceramic coating. In the production process, it is applied by spattering. Some types of film may have expensive pollen in the form of gold or nickel. The material is different from the usual self-adhesive film and is designed specifically for glasses. These are products of roll type, differing in size and density.

A separate type is liquid film for windows. This material is in 1, 5 l buckets to temporarily protect various surfaces from damage, abrasion, and stubborn dirt generated during repairs. This coating is economical - 1 l covers an average of 6 square meters. m square. After application and drying, such a film fits snugly to the base and becomes durable. It can be washed, used for pasting inside the building and outside.

Kinds

The modern market of film coatings for windows offers the customer a wide range of similar products. Among traditional options, a picky customer can buy coverage with a special effect. For example, a film may be:

- athermal;

- reflecting;

- anti-vandal;

- booking;

- perforated;

- architectural;

- heat saving;

- heat reflective;

- stained glass;

- combined.

In this case, the film may be opaque opaque or glossy traditional. To date, it is presented for windows in several varieties. Coatings can be variants of film protection for glass sheets of glass packs or have several functions.

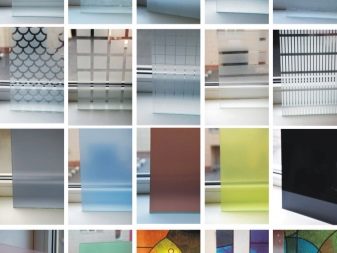

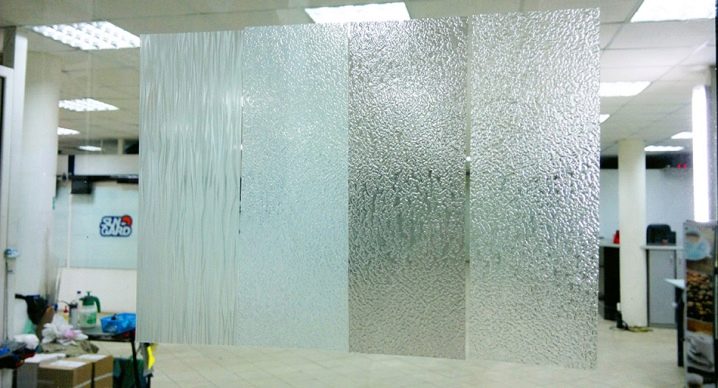

In addition to the functional orientation, the film may be purely decorative. This coating is called stained glass. This is a self-adhesive decorative film with a transparent base and pattern. Its purpose is the partial decoration of windows, as well as the design of glass interior doors. In fact, it is a colorful coating that closes the glass, decorating it. The themes of such films are often geometric shapes, lines, flower motifs.Less often, it imitates the translucent texture of stone, silk textiles.

In some cases, it performs the function of curtains and is presented more as a decorative element indicating that it belongs to a particular style. Stained glass film can have a simple pattern, covering only the lower part of the windows. It is used more often on windows, the frame of which consists of 6-12 small glasses. The film is filled with fragments flush, and the lines of the overall pattern may not coincide.

Sometimes the coating simulates a frosted glass with a transparent pattern. In other cases, the print depicts window openings divided into many small windows. This film is used in different rooms of the dwelling, including glass curtains in the bathroom and bay windows. It does not interfere with the opening of windows, is able to imitate a different pattern, carved on glass up to the skin of python.

Products with a functional bias are divided into several varieties. These include sunscreen and energy-saving coatings. Each type has its own categories. Products differ in type of fastening. Some options are fixed on the inside of the home, others should be fixed from the street.The former are often distinguished by a wide color scheme, the latter are characterized by a reinforced coating of the upper layer, which protects the surface from negative environmental factors.

Sometimes the film is stuck on the glass during its production. In addition, any type of film coating is certified. It indicates its compliance with sanitary and epidemiological standards. Interior and exterior coverings differ in characteristics and resistance to external factors. These are products that are safe for human health and do not emit toxic substances and are not susceptible to the emergence and spread of microorganisms.

Sunscreen

Included in this category are sunscreens to reduce the luminous flux that enters a room through glass. Depending on the variety, they may have one-sided visibility of the glass sheet after mounting the film. Coatings are designed in such a way that it is not visible from the street what is happening in the room. Even outlines will not be visible, the room will not be fully visible. However, being inside the room will see everything that happens outside.

Foil

The budget type is foil film materials based on polyethylene in rolls. Such coatings are used in heat, fixing to the glass from the inside. Unlike most varieties, they do not have a sticky backing. Fixation is carried out by means of adhesive tape.

After the decline of heat they are removed. There is no tight attachment, and to see through them is problematic.

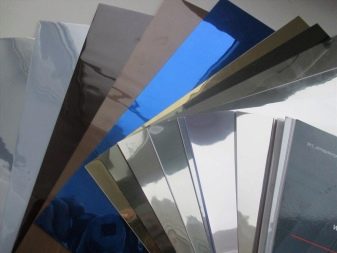

SLR

An alternative to them are mirror counterparts with tinted. They are used for plastic windows. The quality and performance of such a film is quite high. It is characterized by durability and durability. With proper labeling on the glass, it will last for several years.

Due to aluminum and tin oxide in the composition of the layers, the roll film reflects outwards visible light as well as infrared radiation. In comparison with the budget analogue, it is distinguished by aesthetic appeal. Architectural variety protects the glass from mechanical damage. It provides for pasting outside. At the same time, the reflective light of its ability is no less than the classical analogue.

Tinting

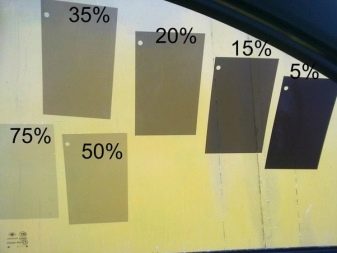

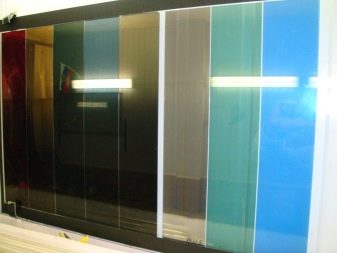

The main difference between such varieties and mirror counterparts is the fact that instead of reflecting visible light and infrared radiation, they absorb them. However, the effectiveness of films in this category depends on the degree of toning. The film can be dense or completely transparent: the coefficient of efficiency varies from 15 to 60%. In this case, the film is different in appearance: the smaller the tinting, the brighter and brighter it conveys the image of what is happening.

The disadvantage of tint coatings is cutting off most of the visible light flux. Especially this factor negatively manifests itself in cloudy and rainy weather, making the room dull and gloomy.

The lack of illumination of the space inside the house (apartment) can provoke depression. Therefore, the use of such a film must be approached thoroughly. For example, it is undesirable to glue it if the windows overlook the north or west side.

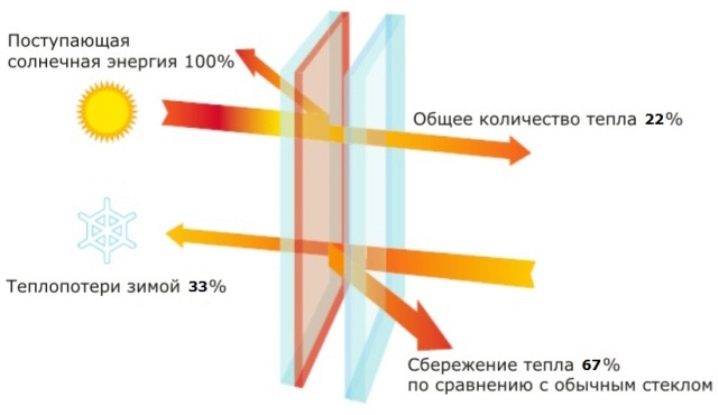

Thermal insulation

The principle of operation of such a film is different from sun protection counterparts. All covers of the line are aimed at minimizing the heat loss of a particular room.In fact, they can be called an alternative to energy-saving double-glazed windows. Their purchase will save the budget, and installation will cost less to replace the glazing. Such coatings do not change the quality indicators under the influence of temperature changes.

The reflection of a fairly high percentage of rays occurs inside. The level of inhibition of daylight does not exceed 30%. This is a thin laminate characterized by transparency. To increase the heat-reflecting and energy-saving properties in the production of such a film, alloys of silver, chromium, and nickel are used. Energy-saving film can be combined with a protective function of preserving glass.

Advantages and disadvantages

The demand for films for windows is due to its merits, among which are the following:

- It is universal. It can be used for residential and non-residential building windows.

- The coating is capable of filtering solar radiation without diminishing visibility.

- It is durable. When buying quality material, it will decorate the surface of windows for at least 5-7 years.

- The material is quite thin. It does not weigh down the weight of glass, even if you use multi-layered varieties for stickers.

- Wide range of.The market of such materials presents a wide range of products for every taste.

- Practicality and aesthetics. Such coatings look stylish, beautiful and attractive.

- Availability. Window film can always be found on sale in specialized stores or on the websites of official suppliers.

Such products are manufactured by many brands. In the market you can find varieties of domestic and foreign manufacturers. Coatings are produced on modern equipment, taking into account new technologies. This allows us to achieve high practical and operational characteristics. By absorbing the energy of the sun and absorbing light, the film is capable of eliminating sun glare.

By and large, all varieties can be called defensive. Even if the glass is accidentally broken, the adhesive layer of the film is so sticky that it will not allow fragments to scatter. At the same time he will soften the blow. Additional advantages are the unlimited possibilities of using film coatings in different areas of stylistics. They can decorate houses or apartments in classic, modern, ethnic, vintage and trendy design directions.

With a lot of useful functions, the film coating for glasses has drawbacks. For example, the main one is the impossibility of adjustments. In addition, the buyer does not always have the ability to check the uniformity of spraying. In rolls, it is not visible how good the seller offers.

In addition, this film is not suitable for use in greenhouses and greenhouses. This slows down the growth processes of plants. The same effect is observed in the apartment. If there are live plants on the windowsill, their growth will slow down due to the film. From lack of light, they will become weak, prone to disease.

The desired effect of the film is possible only in the case of proper installation. If the amateur is engaged in the sticker, the quality of the coverage and the required capacity cannot be discussed. In this case, the effectiveness of the coating will be significantly reduced. In addition, it is worth considering that cheap varieties of domestically produced films, according to customer reviews, partially melt in the sun, sticking tightly into glass.

The difference in color, which may be accompanied by discrepancies in color in different rolls, is also important.This is true when it is planned to cover all the windows of a private house or a two-story cottage.

To avoid this, the buyer must choose a film from one series. With its shortage, you have to abandon the material you like in favor of another.

What is needed?

Using the film allows you to solve several problems. In addition to improving the comfort of households, such coatings are a kind of glass booking. They enhance the glass, affect the transmission, absorption and reflex properties of glass. Due to the film pasted on the surface of the glass, it becomes more durable and resistant to mechanical damage.

If suddenly for some reason the glass breaks, it will not break into a pile of small fragments. Regardless of the location and proximity of furniture, it will remain on the film and will not cause harm. Do not suffer households, do not have to go through several times with a vacuum cleaner, collecting microscopic glass. At the same time the broken glass will not damage the furniture standing next to it.

In some varieties, the film can become a kind of conditioner.This factor is especially important for the modern person and families with children. Film coatings for windows are used in private apartments, common areas, hotels, and entertainment facilities. Due to their capabilities, such coatings are recommended for use in regions with high levels of radiation and high solar activity.

In addition, the use of film allows you to change the approach to the design of windows. This will especially appeal to those who prefer non-standard stylistic solutions in creating an interior composition. If you choose a beautiful pattern and texture, you can use window film instead of curtains. Decorative coatings can be transparent, painted, tinted, translucent and matte.

Their choice depends on the purpose of the film and its decorative possibilities. For example, most matte film materials are used to conceal a view with a simultaneous decorative function. They are used in bathrooms, toilets, interior doors, offices. Often, decorative varieties are the highlight of the design of the facade of the veranda, bay window, closed gazebo.

How to choose?

The choice of film for windows is not as complicated as it may seem at first glance. However, not every coating on the store counter worthy of purchase. It is necessary to take into account the purpose of the material: its throughput properties depend on it. The film is different, its light transmission ability ranges from 5 to 50%.

In fact, the first thing worth paying attention to is the price. Negative customer comments are associated with the acquisition of the film "know his name." This is a low-quality fake, which is issued for goods with special properties. During operation with it there are more problems than good. When a suspiciously low price is worth considering the quality of coverage. The cost of the film ranges from 280 to 500 rubles per 1 meter.

It is worth paying attention to the desired effect, which is a priority for the buyer.

- If you need to reduce the intensity of the light flux and the level of radiation, you should buy a sunscreen film.

- If the requirements remain the same, but I want to hide the internal space from prying eyes, it is better to look at the mirror coating with one-sided visibility.

- When, in addition to functionality, it is important to have graphics with imitation of stained glass, it is advisable to buy a decorative variety.

- To decorate the facade from the street, take the film marked "architectural."

- If the purpose of the purchase is to protect the glass from breaking, it is better to search the range of anti-vandal coating.

- When you want to hold the heat indoors, choose energy-saving film.

Before you give preference to any of the options, it is worth scrolling about it reviews of buyers and master installers. It is better to look at information on several forums dedicated to the finishing of windows. This will provide reliable information about the product quality of a particular brand, durability and film adhesion. The choice of color, which is selected based on the level of transparency, also matters.

For example, green, bronze and violet make up 15%. Varieties of gold, gray, blue, warm bronze tones range from 15 to 35%. Smoky shade is 20, and silver reaches 50%. The higher the percentage, the more transparent the coating.

Hue is selected in such a way that it looks harmoniously against the general background of the interior or exterior.

How to buy quality?

In order not to doubt the quality of the film, you need to take into account several nuances.To get started is to look at the range of the store. After selecting the film is to make sure that the brand really produces such a film. If desired, you can check with the manufacturer whether the seller is his official supplier. Further technology is as follows:

- in the store they ask for a certificate of quality and compliance with the established regulations;

- consider packaging, relating it to the one presented on the manufacturer's website;

- clarify the degree of transparency;

- select the desired effect;

- choose the desired shade and texture.

It is worth paying attention to the packaging. A quality product has no tears, torn edges or a yellowish background.. This indicates a low quality and obvious fake. Any change to the logo on the label also indicates falsification. As a rule, such films have poor-quality and non-uniform sputtering. In addition, quality goods are not sold on sale at a discount. This is nothing more than a tricky move on the sale of unmarketable goods.

It is worth paying attention to such a moment when on the shelf one of the materials is present in small quantity. This is not a sign of quality and demand.So the buyer is forced to buy something that is not in demand.

It is possible to distinguish a heat-shielding covering by means of a usual lighter. This will allow you to understand how the material corresponds to the withered effect. When you bring a cigarette lighter to the coated glass, you can see:

- 4 reflections of the flame (2 closer and 2 near);

- 1,2,4 flame reflections will have a natural tone;

- The 3 reflection (farthest) will shine a pinkish-red light. It is a reflection of red and indicates the energy-saving effect of the coating.

How to paste?

Pasting of a glass cloth with a film depends on a type of a covering.

Liquid

If it is a liquid form, a surface is prepared before applying the finished material. It should not be dust, dirt and grease. All this is removed, the glass should be clean washed without staining. After the surface is dry, apply a film mass.

To do this, use velor roller and a clean container. Having lowered the roller in capacity with weight, it is impregnated with solution completely. Then gently squeeze out, so that the film is uniform. Liquid film is applied in a double layer on the frame and seals.In addition to the roller, airless spray can be used for application.

You must first carry out a test spray.

Roll

Pasting the film in rolls is simple, but requires consideration of some of the nuances. Their knowledge will allow fixing on a professional level without air bubbles and coating deformation. If you ignore the accuracy of the glass surface will show all the defects of the work. It is worthwhile to dwell on the fixing of such a film, since it is precisely it that is bought more often, but they do not know the simple rules of application.

Tools and Training

In the process of fixing it will be difficult to find the right tool. so before pasting you need to prepare:

- roulette wheel;

- line of steel length 50x100 cm;

- a steel blade with a retractable blade;

- rubber spatulas up to 7 and 15 cm wide;

- construction knife;

- pure water spray;

- thin medical needle;

- non-woven rags;

- suede for polishing glasses.

In addition, it is desirable to prepare a substrate for cutting the film. When inventory is prepared, inspect the base under pasting. Glass must be intact. Any cracks, twists, scratches will be visible (especially with a transparent film).If there is paint residue on the glass, fat, insect excrement, it is removed with the use of surfactants (surfactants). Can be used:

- household soap solution;

- window cleaner;

- baby shampoo;

- washing powder.

Cleansing is done with a window scrubber. Dry cleaning is not allowed. This will cause cloudy spots and microscopic scratches. To add shine to the glass surface, you can add a little ammonia to the detergent.

Be sure to degrease the base. To do this, you can use acetone or gasoline for lighters. The procedure is performed for 10-15 minutes before the start of pasting.

Technology works

When all the accessories and material are ready, proceed to pasting. Surface have back up. This is a substrate with applied markup, which contributes to a more accurate fit of the film to the desired shape.

Stages of work:

- the film is placed on a flat surface, straightened and pressed down at the corners with a load (books can be used);

- using the tape measure the required size of the canvas;

- on the back side with the markup plan the desired size of the part;

- using scissors or a construction knife, cut out the necessary fabric with a small allowance;

- begin to glue on top: first, the cloth is applied to the desired place, then the upper corners of the substrate are folded over and fastened.

You can not remove the entire layer of the substrate. The maximum it can be removed no more than 3-5 cm in width. The final result will depend on how accurately the canvas is applied at the beginning. Re-glue the film does not work, so everything should be perfect right away. If it is stripped, the glue will remain on the glass, which will lead to the need to replace the film and clean the glass sheet.

To work was of high quality, gluing is performed with a rubber trowel. It will eliminate the formation of air bubbles. Due to smoothing and pressing down to the base, the coating will have high adhesion. Partial removal of the protective layer from the back side will prevent dust or fine debris from falling on the sticky layer. If a bubble has formed, it is pierced with a needle.

The remaining allowances are trimmed after the main sheet of the film is already fixed.For maximum accuracy, it is best to use a construction or stationery knife with a retractable blade.

The blade must not have chipping, otherwise it may tear the film. It can ruin all the work. It is held at an angle of 15-20 degrees relative to the plane of the glass and tightly pressed to the edge of the bead.

How to remove?

If you need to replace the film, you have to remove the old coating. This is due to darkening, turbidity, the formation of scratches on the surface during operation. You can not just hook and peel it, as in some cases it will break apart and make further removal difficult. Usually high-quality coating is easy to remove. To do this, pick up a corner and pull the film, removing from the glass.

As a rule, a sticky layer remains after removal. It is removed using a soap solution. If the coating is firmly stuck to the glass sheet, it will have to be heated with a hair dryer. The heating procedure will reduce adhesion, the coating will be easier to remove. Remnants of the adhesive layer can be removed from the base with Cosmofen 10 or Fenosol.

The use of water in the space between the film and glass is not always effective.If you remove the film is difficult, you can use the drug "HG Sticker Remover." In this case, the edge of the film is folded over and the surface is treated with the agent. After removing the film with this drug, you can remove the residual stickiness.

Care

During the operation of the film coating, dust is deposited on the surface, contamination appears. However, the film can not be cleaned by household chemicals. The use of hard sponges or coarse rags is unacceptable. Dust is easy to remove soft suede for polishing. It will not leave stains and will not damage the film.

If the contamination cannot be removed with a dry soft cloth, you can use a regular soap solution, gently scrubbing the contamination with a soft sponge or microfiber cloth.

Do not pour water on the surface and soak it. The use of a vacuum cleaner and a glass scrubber is unacceptable. Do not rub the solution inside: cleaning should be soft and superficial.

Tips

In addition to the choice with an emphasis on functionality, we must not forget about the conformity of the coverage of the concept of the chosen style. In other words, it is necessary that the film be practical and successfully fit into the interior or exterior. It does not matter the type of building.Both the apartment and the private house are equally in need of harmonious design creation.

The quality of fixation of the film depends on several nuances:

- optimal temperature range varies within +5 + 40 degrees;

- humidity can vary from 20 to 80%;

- if the room is dry, water can be sprayed;

- when cutting the workpiece give an allowance for the length and width of 5-10 cm;

- it is better to pick up the film without docking;

- For the substrate of the film when cutting, you can use a fiberboard.

The film sticks and magnetizes in the process. On the surface and under it can get dust particles or small debris. To prevent this from affecting the quality of pasting, it is necessary to treat the coating with an antistatic for clothing or car dealerships (without a silicone additive). Do not wipe the garbage with a damp cloth.

When performing cuttings, masters recommend breaking off retractable blades to maintain their sharpness. Glass is a hard and durable material. If you do not change the blade, it will become blunt and may cause tearing of the film.

If during the work you have to pierce the film to remove the air bubble, you should immediately trim this area with a rubber spatula.If the air pocket is large, it is smoothed from the edges to the puncture site.

Learn more about how to choose the film on the window, you will learn from the following video.