Features and use of MDF panels for furniture

Today, MDF (fine fraction) is used not only for wall cladding, but also for the production of furniture. This material is popular because of its durability, thermal and moisture resistance, the possibility of choosing almost any texture and favorite color. Manufacturers offer MDF in the form of sheets, panels or facades in ready-made furniture sets. This article discusses the features and nuances of the use of MDF for furniture.

Distinctive features

MDF consists of two panels with sawdust pressed between them. The material is more durable and environmentally friendly than chipboard, the production of which uses synthetic resin.

The advantages of MDF are:

- scratch and chip resistance;

- high strength, wear and moisture resistance;

- MDF is easy to clean and does not require the use of special cleaning products;

- the possibility of manufacturing figured front doors and drawing a pattern on them by milling;

- furniture made of MDF looks very similar to solid wood furniture;

- subject to the technology of lacquering, you can get the effect of cladding glass;

- Such material fits into almost any interior, it imitates almost all types of natural materials and comes in many different colors.

For all its merits, MDF panels have several significant drawbacks:

- production time is at least three weeks;

- there is no possibility to “fit” the size of the finished product;

- high price (when compared with the cost of chipboard);

- Painted material is difficult to maintain, and laminated is not resistant to high temperatures and moisture.

Types and forms

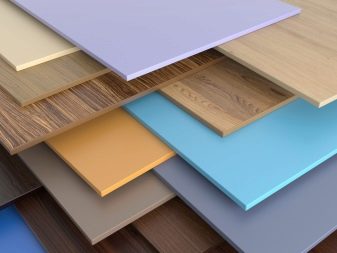

MDF can be divided into several types depending on the method of surface treatment. Ground on one or two sides of the plate is well suited for putty and paint. They are most often used in the decoration of walls and ceilings.Panels with a thickness of more than 12 mm can also be used for flooring, they are used instead of laminate.

Laminated (with PVC film) on one or two sides of the plate are used both in the production of furniture and in the creation of wall panels. Even a worktop or furniture in the bathroom can be made from such material if it is pretreated with hydrophobic additives.

PVC film It is made from synthetic polyvinyl chloride, which becomes plastic when heated. Under the influence of vacuum, the heated film is pressed tightly to the facade workpiece, and when it cools down, the resulting relief is preserved.

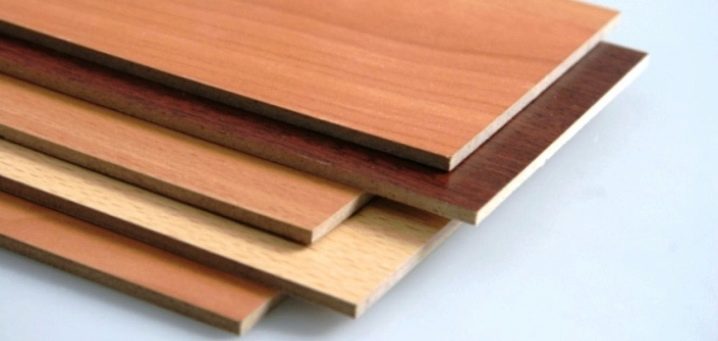

Veneered slabs - these are the plates pasted over with thin sawn wood (veneer). Such plates are very similar to an array of valuable wood, and therefore their price is quite high.

Another type of MDF, which is mainly used in furniture production, is plastic coated panels. They do not fade under the sun and are easily cleaned with any cleaning agent, which is especially important for kitchen furniture. Plastic panels allow you to make curved contours and rounded shapes.

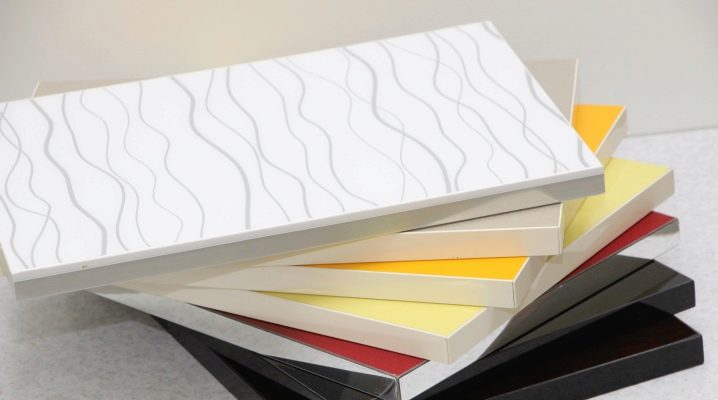

3D panels - a novelty on the building materials market. Processing of such facades is carried out not only along the contour, but also into the depth of the surface. With the help of milling on the front surface of the facades, various patterns “under the tree”, “under the waves”, “under the sand dunes” are created. The second option for obtaining the 3D effect is multiple staining of MDF, which is then laminated or covered with veneer.

The form of MDF can be divided into three types:

- Rack tiles - panels 15–32.5 cm wide and 240–270 cm long. Light stripes of material, similar to long laminate boards.

- Tiled - square panels with sizes from 30x30 to 95x95 cm, similar to a large ceramic tile.

- Sheet - moisture-proof panels with a height of 2800, 2440, 2344 and 2070 mm, width - 1220, 1035 and 695 mm. Remind the surface of the wall, lined with small and medium tiles.

Manufacturing process

To clearly understand what constitutes a ready-made panel of the fine fraction, it is necessary to have an idea about the process of its production. At the first stage, the necessary raw materials are harvested: the logs are cleared of bark and crushed with special equipment into chips. Then the chips are sorted, washed from various debris (in the form of sand or small stones) and heated by steam.

In the second stage, the chips are crushed in a refiner until lignin is released - a binder that allows the wood fibers to form a single material. For better bonding, various resins can be added. Then you can remove the air from the resulting mass and send it to the molding.

In the third and fourth stages, the mass is rolled out and pressed several times - until the air is completely removed. Then it is cut into finished plates and cooled. Then polishing, and also adjustment of thickness and various defects is carried out. So it turns out the usual polished MDF, which in the future it will be possible to apply paint, veneer. It can also be laminated.

Facade

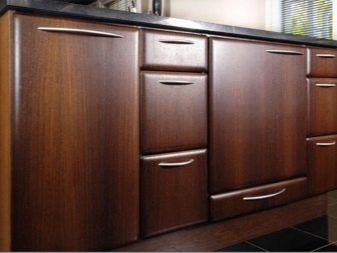

The most common option is to use MDF only for the facade of furniture, and all other parts of cabinets, shelves and pedestals are made from cheaper chipboard. MDF is valued for its ease of processing, aesthetic appearance and the ability to assemble and disassemble a product several times without compromising the strength of its joints.

The production of this material has its own characteristics and consists of several stages.

- Sawing of MDF board according to the specified dimensions is carried out in special format-cutting machines equipped with circular saws.The panels are fed backwards at high speed so that the ends do not leave traces of teeth from a circular saw. To increase the speed of work in the production of identical parts, several plates are stacked on top of each other and fed to the saw in a stack. Several MDF panels are folded and glued together to obtain the required thickness of the product.

- Bringing the facade or table top to the final exact dimensions by milling at the corners, along the edge and surface. A 2–3 mm radius cutter cuts the corners of the workpieces to remove sharp elements and defects that not only spoil the appearance of the products, but also can lead to injuries. A chamfer is removed along the edges in order to also remove the edge sharpness. Alternating the cutters of the required radius, they process the very edge. With the help of milling the surface is prepared for painting and polishing - or perform various patterns on the workpieces of the facade. After milling, all surfaces of the resulting product are carefully polished.

- Lamination (lamination) of a facade is the process of coating the treated MDF surface with a special facing film or paper (using membrane-vacuum pressingequipment). Special glue is applied to the surface of the blank, paper or film is cut off. Facades are laid on paper and placed under a silicone membrane, which squeezes the excess glue from under the coating. After the glue has completely dried, the excess paper or film is carefully trimmed.

- Preparation for transportation or storage. It is necessary to pack all MDF parts separately, wrapping them in plastic wrap so that no dust or moisture gets on the facade. Then several items are packed in corrugated cardboard to avoid mechanical damage.

To store products you need horizontally laid on wooden shelves or pallets (in a dry room, with a temperature of at least 0 and no more than 35 degrees).

To avoid deflection on large parts, packages should not hang down from the shelf or stand at the end at an angle to the floor. Transportation is carried out with the help of containers or a car with a closed body. The corners should be additionally wrapped with cardboard to avoid damage when moving.

Operation and care

Facades made of MDF are installed indoors (with air humidity up to 80%).Placing near stoves or stoves is undesirable, as high temperatures can damage the PVC film. It is advisable not to expose facades to contact with sharp objects, to avoid shocks and friction.

To care for furniture with a MDF facade, a soft cloth or sponge is used. and liquid detergents that do not include powder, chlorine or solvent. If there are grease stains on the façade, you can remove them with a drop of vinegar added to an ordinary cleaning agent. With proper operation, wet cleaning is required 1-2 times a year, not more often, and the rest of the time, facades can be wiped with a dry lint-free cloth.

Work with facades is carried out exclusively on smooth surfaces to eliminate the appearance of scratches. The protective polyethylene film from the facades is removed only after the final installation of the furniture.

Examples in the interior

Classical kitchen from MDF under an array of nuts. The work surface and table top are made in white to visually highlight the space. On a white surface, less visible dust, as well as water droplets.

Modern kitchen design with the use of 3D effect on the facade of MDF.The upper part of the headset, made in a light color, is connected to the dark lower part with the help of the same relief on the doors of the cabinets.

Bright kitchen MDF with plastic frames on the doors. This frame not only looks good on the headset, but also protects the edges of MDF from deformation under the influence of water, heat and other factors.

To learn how to make furniture from MDF panels, see the following video.