How to insulate the floor with expanded clay?

Heat in the house depends on the condition of the floors. Cold floor is able to absorb from 10 to 15 percent of heat energy produced by heating devices. Therefore, during the construction of this structural element should be thoroughly insulated.

An excellent type of insulation is expanded clay. If you do not know how to use it for this purpose, we recommend that you read this article.

A bit of history

The appearance of the clay is due to defective brick. At the beginning of the last century, red brick was produced industrially. When the duration of heat treatment increased or the temperature exceeded the permissible value, the brick turned out to be burned out, swell. Non-standard crushed and used as a filler for concrete.

If in our country they did not allow bricks to be unsuitable for construction, in America, porous clay plates were specially made.And they used them similarly with our marriage.

The thirties of the 20th century were marked by the fact that this technology was modernized. The Soviet engineer suggested making small porous fractions at once. Clay granules were heat treated in rotary kilns. A solid layer appeared on their surface. The granules had a low weight, as there were many air inclusions inside. So came clay.

Material Features

For household, claydite is simply indispensable. It is used in the design of the drainage system, they lay out garden paths, used in landscape design. But, first of all, this material is known as a first-class insulation.

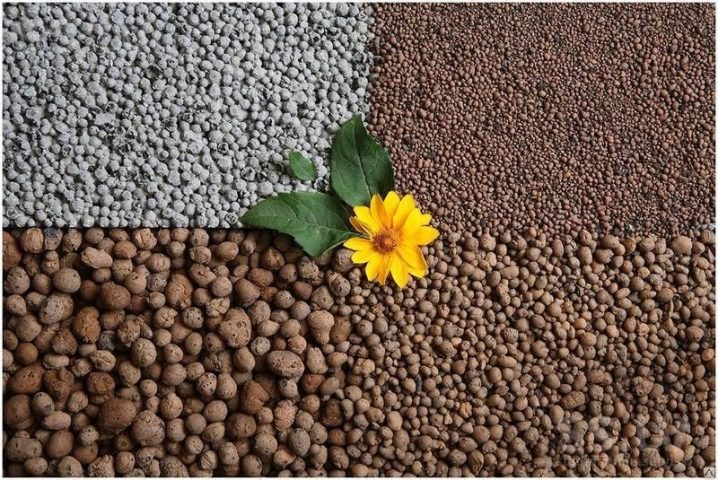

Porous granules, depending on the size, are divided into three groups:

- Small from 5 mm to 10 mm are the main components of blocks of expanded clay concrete. In construction works suitable for arranging floor screed.

- Mid-sized from 10 to 20 mm are used as insulation for floors and ceilings between floors in private homes.

- The largest from 20 mm to 40 mm go for floor insulation in basements and garages.

The shape and structure of the material has three varieties:

- Expanded clay gravel. The distinctive characteristic is porosity and rounded shape. The sizes of balls vary within 5 - 40 millimeters.

- Expanded clay sand. Particle size does not exceed 5 mm. Formed from gravel residue. Used as a filler for cement mortars and ultralight concrete.

- Crushed stone The dimensions are similar to gravel, but the particles are distinguished by the presence of angles, chips, hollows. It turns out when crushing overly coarse gravel. Goes to the filling of lightweight concrete.

Advantages and disadvantages

The granulated bulk material has many advantages. The main thing, perhaps, is the ratio of quality indicators and cost. Unfortunately, it was not without flaws. Therefore, you can hear the opinions of the pros and cons of its use.

Indisputable advantages of claydite:

- Good thermal insulation properties. Clay, which is used to make expanded clay, and is itself capable of retaining heat. After foaming, air-filled pores are formed in it, due to which the thermal conductivity is significantly reduced.

- Low weight. Despite the fact that during the warming of building structures, claydite is poured in a sufficiently thick layer, the load on the base of its weight is small.

- Easy to use.Work with the material does not require special skills and the use of special expensive equipment.

- Incombustible. Expanded clay is not burning. When heated, it does not emit toxins and unpleasant odors.

- Unsuitable for rodents and insects. Insulation will not collapse from the invasion of various living creatures.

- Resistance to heat and chemicals. Granules will not collapse during heat or cold, will not lose their insulating properties when interacting with household chemicals.

- Soundproofing. Along with the properties of insulation, expanded clay significantly reduces the penetration of noise.

- Environmental friendliness. Absolutely harmless to humans and pets.

- Durability. Expanded clay pillow under the rules of laying can serve a whole century!

In the absence or damage to the hard shell moisture penetrates into the granules. Raw clay is not suitable for use, and it dries for a very long time.To prevent moisture absorption by the insulation during installation, additional materials are used: waterproofing from below and vapor insulation over the insulator. Failure to follow the rules will lead to the penetration of moisture into the granules. Then the clay will get wet, its weight will increase, and it will drain in places. Useful properties will disappear.

Styling Features

There are three different ways to use granulated insulation.

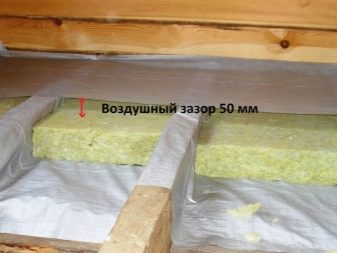

The dry method is preferred in wooden houses. Gravel is mixed with expanded clay sand and poured into the intervals between the lags. Thanks to particles of various sizes, the space is filled as closely as possible. Lack of gaps guarantees reliable warming. The dry method is the fastest. It is a force for people without experience, does not require large expenditures.

The wet method is a coupler of three components. Two parts of sand are mixed with one part of cement and three parts of expanded clay. The mixture is well mixed with water and the resulting solution is poured over the floor. The presence of porous balls in the screed provides floor insulation.

This technology is used in utility rooms: garages, workshops, sheds.The method is time consuming and more expensive than dry.

In the combined method, dry granules are only poured on top of the cement mortar. So get a flat solid surface. After drying, make a complete screed.

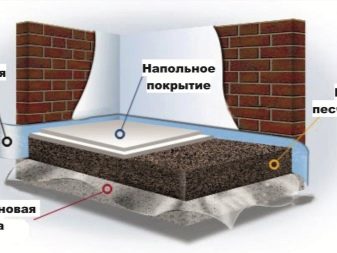

In order to insulate the foundation, floor, ceiling or ceiling with the help of expanded clay, similar technologies are used. At first the platform on which it is planned to fill expanded clay is leveled. Then waterproofing is laid, it can be plastic film or other rolled material that is not permeable to moisture. In order for the waterproofing coating to become solid, the joints are carefully glued with tape.

The thickness of the thermal insulation layer depends on the floor construction. The thicker the layer, the better the insulation and the more heat remains in the room. Sometimes the height of the backfill is limited by the size of the lag, sometimes it depends on the existing doorway, when an extra centimeter becomes a barrier to the door.

On large areas it is difficult to ensure uniform laying out of expanded clay. The problem is solved by installing wooden bars or lags. The lags are aligned with the level in the horizontal plane.Then waterproofing is laid. On it granules get enough sleep. The level is re-applied, but now for the correct distribution of the bulk product along the horizon. If the clay goes under the screed, the top layer is filled with cement mortar. In the case of a dry laying method, a vapor barrier, such as parchment, is laid on top.

In order to insulate the chimney, it is necessary to build a casing corresponding to the shape of the pipe. Bottom should be a dense non-combustible material, for example, asbestos-cement sheet. Expanded clay is loaded into the space between the chimney pipe. The upper part of the casing is closed with a lid made of the same material as himself.

Insulation technology

For all the similarity of laying bulk material, there are some distinctive features.

On the ground

The floor on the ground is appropriate in garages and basements. In the winter in such rooms it will not be too cold if to perform the corresponding works.

To warm the floor along the ground, remove the fertile layer, level the ground and compact it thoroughly. A layer of crushed stone and sand is poured on the packed area. Thus, additional surface alignment occurs.

From high-standing groundwater insulation waterproofing protects. It should be put on the prepared pillow. Then pour the clay and align so that the height over the entire area was the same. Fixing the top layer is performed by impregnation with cement mortar. Next comes a vapor barrier.

Warming up on the ground reinforced with a cement screed ends. If desired, a wooden floor can be put on it after it has completely dried.

By lag

Lags at warming with expanded clay serve double service. On the one hand, it is convenient to level the backfill on them, on the other - they serve as the basis for the subfloor.

The lagged granulated fraction is placed on concrete foundations. First, the working area is freed up to pure concrete. Any flaws are eliminated. Cracks are smeared with mortar, joints and corners are foamed if necessary. Lags are pre-treated with an antiseptic, and then they are secured to the base with corners. In this case, the upper edges of the wooden rails are displayed in one horizontal plane.

As a waterproofing, you can use:

- Ruberoid;

- Polyethylene;

- Polymer blends;

- Bituminous mastics;

- Hydrobarriers rubber.

To be processed and the concrete surface, and logs, and the walls around the perimeter of the room to a height slightly higher than the height of wooden parts. In the case of liquid mastic, concrete is primed for better adhesion. If the film is used, it is attached to the bars with a stapler. Insulation is filled in the sinuses so that there is no free space, and the height is the same everywhere. Expanded clay vapor barrier layer. Then set the draft floor, and on it and finish.

On the balcony

In fact, the balcony is a fenced protruding reinforced concrete slab. Standing on a concrete floor is uncomfortable even in summer. Often, apartment owners decide on the insulation of balconies. Light granules are better suited for this purpose than other heat insulators.

Leveling the base is not necessary. The main thing is that the new floor does not have slopes. To do this, on concrete, covered with insulation, install slats-beacons. Lighthouses can be attached to the slab with mortar or plaster. The distance between parallel slats must not exceed the length of the rule. The smaller the step between the beacons, the easier it is to do the work.

The height of the warm layer is equal to the beacons. The finished pillow is poured with cement.After hardening from above, they make a complete screed. Upon request, a wooden floor can be laid on the balcony and on the enclosed balcony over the screed.

In a wooden house

Expanded clay is widely used in the private sector. This is not surprising, since the material is so unpretentious that homeowners work with it on their own.

Expanded clay insulate the floors of the first floor and attic floors. Granular material is used for warming the floor in the steam room, in the outbuildings and residential premises. In the latter case, it is important to ensure that the dust generated by the friction of gravel does not penetrate the room.

A stone or concrete house is built on a foundation and has a basement or basement. In such buildings, floors are not always insulated. It is impossible to live in a frame house built on screw piles without thermal insulation. To ensure comfort in such a structure will have to work hard.

The funds saved on the construction of the foundation should be spent on a thorough floor insulation. As a waterproofing there should not be the simplest roofing material or polyethylene, but modern reliable building materials. An excellent protection against negative impact will be vapor-permeable moisture and wind insulation membranes. The remaining work is carried out similarly to other types of floors.Exactly the same work on floor insulation will require a light wooden timber house.

Reviews

Those who are not yet sure about the capabilities of expanded clay should read the reviews. Users use claydite as a floor heater in the garage. Thanks to this, not only it gets warmer inside, but the car remains in excellent condition longer.

Those who insulated with expanded clay on the floor in a residential building note that after that the heating costs were significantly reduced, even though the heated area could have increased.

The use of expanded clay to insulate cellars allows you to save the workpiece as long as possible, despite the fact that in the winter on the thermometer can be observed extremely low temperatures.

Successful examples and options

Wet laying of expanded clay greatly facilitates work on floors with large differences in height. At the same time granulated concrete filler significantly reduces the load on the treated surface.

The simultaneous use of granules of different sizes (large interspersed with small) contributes to the penetration of particles of insulation, even in hard-to-reach places.

In residential premises, when the floors are heated with expanded clay, a combined method is always used. Strengthening the top layer of cement milk prevents the penetration of the smallest particles of insulation in the air. Failure to comply with this requirement can lead to respiratory problems.

Expanded clay - a wonderful heat insulator. It is light and cheap, non-toxic and durable. These qualities can not be overlooked. Therefore, granulated insulation will be in demand and always needed.

For information on how to equip the floor of the loggia with expanded clay, see the following video.