How to insulate a metal garage: ways and recommendations

An ordinary metal garage can perform many useful functions. For the winter, a car enthusiast leaves his car in it, someone else stores provisions here, and someone equips the space for a special workshop. All this is possible to do under the condition that the garage should be insulated.

The optimum temperature for such a room is at least -5 ° C. At lower values, condensation begins to form on the surface of the car, which causes rust. It will be impossible to work in boxing because of the cold, and it will be inexpedient to store vegetables, they will simply start to rot in the first thaw. In order to keep the room warm, it is necessary to properly select and install insulation.

Heaters

The use of traditional building materials for the garage of metal can significantly increase the temperature in the room.

For these purposes, use:

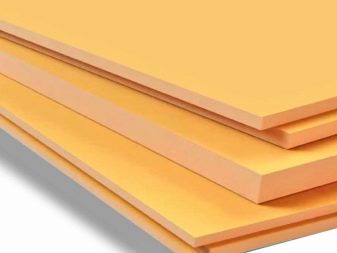

- Styrofoam. This material belongs to the most common type of insulation. It is convenient to work with polyfoam, it costs cheap;

- Penoizol. This is the liquid form of the same foam. Penoizol has fire resistance and excellent water resistance. The durability of such insulation - 40 years;

- Basalt wool. This soft and inexpensive insulation is also called mineral wool. Minvaty often insulate garages. And this material is by popularity among the leaders.

- Polyurethane foam. The durability of this building material is 50 years;

The above-mentioned types practically do not differ in quality, the reasonable price determines the demand for all these products.

Having decided on the type of insulation for arranging insulation from inside the box, you can proceed to the preparatory stage.

Necessary tools and building materials

Insulation of the garage is better to do in the summer or spring. Sometimes the situation forces to work in cold weather, at low temperatures.In this case, it is necessary to warm the garage reliably quickly.

In advance, you need to prepare the tools to make productive use of the allotted time:

- electric drill;

- building level;

- steel profile;

- welding machine;

- shuropovert;

- self-tapping screws;

- furniture stapler with brackets;

- roulette;

- bars of wood to install cross-batten;

- scissors for working with metal;

- protective gloves, special mask.

Training

Being engaged in the inner lining of metal, in the first place should take care of corrosion. If there is rust on the surface of the walls, it should be removed with a special metal brush. If necessary, carry out patching repairs of individual sections. After which the surface is treated with an anti-corrosion solution.

To ensure optimal indoor conditions, you must also create a ventilation system. It will be needed for circulation: the system will remove the exhaust air, replacing it with fresh air. Otherwise, accumulated heavy vapors and gases can cause condensation. Condensation, on the other hand, negatively affects the condition of the supporting structure of the garage, car and stored products.

After applying the anti-corrosion solution to its complete drying, it usually takes several days. After starting to engage in weatherization of the box from the inside. Such work can be done by hand. According to the rules for a start, they insulate the walls, then the roof, the gate, and only then, if necessary, reinforce the protection of the floor.

Wall insulation

Consider the procedure for insulation using the example of such a material as basalt wool.

This type of material has decent characteristics:

- durability;

- preservation of qualities even at high humidity;

- low thermal conductivity;

- resistance to moldiness;

- convenience of working with insulation;

- environmental friendliness;

- fire resistance

The sequence of covering the walls of the garage with mineral insulation:

- First you need to determine the location of the crates. The amount of material spent will depend on the quadrature of the surface being trimmed. Steel profile is great for frame construction. The use of wood in this case can lead to rapid destruction by moisture. In addition, the wooden structure can be deformed when wet.

- Start building vertical guides. The gap between the structures should be about 1-2 cm, that is, less than the width of the insulation itself. So the material will completely finish and will occupy space completely. To reinforce the system, transverse horizontally across every meter is set, wooden beams can be used here.

- Already mounted crate begin to enclose the membrane, you can use another type of waterproofing material. The appeared joints should be glued with scotch tape, the film is fixed on the brackets, for this you can use a stapler.

- Lay the insulation you need inside the resulting crates. Begin laying the bottom. In this case, the cleft should not remain.

- On the insulation impose vapor barrier material, you can use plastic wrap or roofing material.

- At the end sheathe crate. The lining is made with a non-combustible material, for example, they use drywall or steel siding.

It should be borne in mind that when boxing sheathing space in the room is narrowed. Accordingly, it is better to choose not very voluminous insulation.

Sheathing the garage with foam plastic, should be considered a feature of the material. Such insulation will not expand like cotton, respectively, the gap between the guides is better to do a little less, for example by 1-2 cm. It is better to create a crate with separate blocks, the dimensions of each of them should exactly repeat the dimensions of the foam sheets. If there are defects on the walls, then it is better to level the surface before weatherization. It is recommended to use the L-shaped profile. Sheets of insulation are mounted on glue

Roof insulation

Usually the roof or ceiling of the garage is presented in the form of a lean-to design. This design of the roof is considered a budget and a simple option. The basis for it are rafters, based on the mauerlat.

At the stage of its construction

Now we will continue the work. Mauerlat bars are laid on top of the walls of the box, fastening anchor bolts. To insulate the ceiling of the iron garage is better at the stage of its construction. In this case, the work will take less time and effort.

The rafter system is collected from wooden beams. The cross section of each bar is 15x15 cm. The rafters are installed at a uniformly uniform distance, the gap reaches 60 cm.The main guideline in this case is the width of the insulation plates, according to the standard, this size reaches 61 cm. The maximum insulation elements are dense between the rafters and you can lay them in the presence of a stock.

The next step will be the arrangement of the vapor barrier layer. For this you can buy special membranes perfectly suitable for these purposes. They are attached to the rafters with clips, buttons. Existing joints are taped. Inside the vapor barrier sheathe selected material. Here you can use hardboard or wall paneling. This is an individual solution for each garage owner.

The casing is mounted very carefully, it is necessary to monitor the tightness of the vapor barrier. Damage or defects that appear during operation should be immediately repaired. To do this, you can use a sealant or adhesive tape.

Insulation fits between the rafters. It is better to choose such work for such work. Usually, it is considered sufficient to use a heater with a thickness of 15 cm. The heat-insulating layer can be increased if necessary.

Then spend the standard technology for the arrangement of the roof. First, the crate is made.The order of installation depends on the characteristics of the used roofing. After waterproofing is applied to the crate and the work is completed by laying the finishing material.

Insulation after the construction of the garage

The construction of the ceiling insulation, carried out after the construction of the garage, is slightly different from the process of warming the roof during the construction of the box. In this case, the thermal insulation is placed between the rafters, a vapor barrier film is laid on top, and in the end the structure is sheathed with any suitable material.

Certain inconveniences may occur in the process of mounting insulation boards. To eliminate the inconvenience, the insulation is simply enough to fix, in order to avoid material falling before the start of the finishing plating. It is necessary to fasten strips of waterproofing, vapor barrier material to the slings so that they prevent the insulation from falling.

It is considered inconvenient to work with hard materials, therefore, it is better to sheathe the garage ceiling with foam plastic. At the same time, there should be no openings on the roof surface outside and inside. If the holes in the ceiling are still there, they must be eliminated by welding.The foam at the time of insulation have between paroizoliruyuschem and waterproofing material.

Entrance panel

With the ingress of cold air through the cracks located in the entrance gate of the garage, there is no benefit from the insulation of the internal walls. To solve this problem will help laying hard insulation such as foam polystyrene. To start insulate the gate, and then the front door.

Sequencing:

- The metal surface of the gate is treated with protective mastic. Such material as polystyrene foam is not afraid of the negative effects of moisture. That's just opening the door, snow or raindrops can sometimes penetrate the crevice, being between insulation and sheet metal. This can not be allowed.

- Around the perimeter of the garage door secure crate profile.

- Next, fix the layers of polystyrene on a special glue. It is better to apply penofol made of foil to sheets of insulation.

- Next is the crate of wooden bars necessary for the subsequent installation of the cladding. The gap between the cladding material (drywall, wall paneling or other) should be maintained within 30 mm.Such space is necessary to create an air gap.

- After fixing the lining on the crate, the same work is carried out with the door.

Floor insulation

In rare cases, there is a need for warming the garage floor. For example, if there are large cracks or a basement in the floor of the box. In this case, the foam is considered the best for warming the floor, on top of it you can lay a material that will prevent the destruction of insulation while moving people.

You must do the following:

- To level a surface of a floor, having smeared existing putty and cracks with putty.

- Apply a double coat of primer to the concrete floor.

- Prepare and install the crate of the steel profile.

- Lay a layer of waterproofing.

- Apply glue to waterproofing material, lay foam sheets with a clip to the surface.

- Make a floor screed with a special mortar. To increase the strength of the coating add the extradited granules.

All the works described above will help to create and maintain a normal microclimate inside the garage for a long time. By the way, even a person with no experience can insulate a garage. Such work is on the shoulder beginner.The result will be a warming room, inside which a car, food or other valuable items will be safe.

How to insulate the garage, see below in the video.