The subtleties of the sealing of drywall seams

When making repairs indoors, it is important to choose a suitable inexpensive material and use it properly. For the decoration of the walls of the master often use drywall. Unlike other materials, its installation does not take much time, while it can be of any shape.

People who have never engaged in repair work will be pleased with the fact that the installation of drywall is not as difficult as it seems at first glance: you can cope with it, even without experience. We understand the intricacies of the sealing of drywall seams.

Special features

When performing installation work on installing drywall seams will be in any case. Their width depends on many factors. It is even necessary to take into account how the gypsum plasterboard sheets will change under the influence of temperature. To seams were not visible, they must be sealed with putty.

If the work is performed incorrectly, after a certain period of time, small cracks may appear on the joints between the plasterboard. If you skip this step, the surface will be uneven, and the sheets will deteriorate in the future. They will be exposed to high humidity and pass the test of time. After sheets of drywall are covered with paint or other materials, stains or wallpaper may swell up near the seams.

What to fix?

To seal the holes between the sheets of drywall, you need to choose high-quality putty and tools with which it will be applied. First you need to choose a spatula. Choose the one that is easiest to work with. The choice depends on the master.

Both narrow and wide spatula are suitable for working with putty (the main thing is that its blade is flexible enough). This can be checked by simultaneously bending the blade and the handle. They should not break or crack.

In addition to the spatula in the work may be needed:

- paint brush;

- sandpaper;

- Sander;

- drill with a special nozzle "mixer" for the preparation of the mixture.

An important role is played by the choice of putty. It depends on what will be the further decoration of the walls. On the modern construction market there are many varieties of this material, among which you can buy cheap and expensive raw materials, which differ in purpose and quality.

If the walls are simply painted, you need to use a simple putty for the seams. It will be enough for the walls to be of high quality and attractive in appearance. If the walls are prepared for sticking with wallpaper, any starting or finishing mixture will do. It is not necessary that she was expensive.

You can take a simple plaster base from a quality manufacturer. The main component of this plaster is gypsum, allowing walls to breathe.

The only drawback of gypsum plaster is the fact that it quickly sets. Because of this, you have to work quickly, managing to apply a new layer.

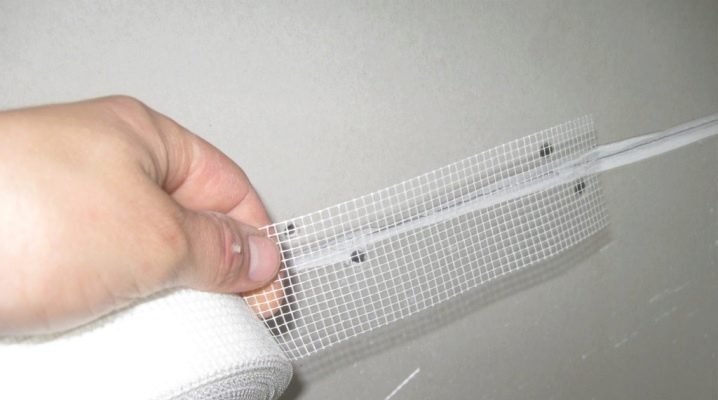

To work with seams, you may need paper tapes, serpyanka tape or reinforced mesh, with which it is easier to glue transverse, as well as longitudinal seams. A paper tape with a groove in the middle makes it easier to work with the inside corners of the seams..

In order not to form bubbles under the paper layer, it is necessary to purchase a special tape with micro-perforation. Serpyanka tape is often used for longitudinal seams.

It stretches well, but in terms of strength it cannot be compared with scotch tape. Although she has an advantage: it is easily glued. If the master made a mistake, it is easy to peel it off, leaving no visible marks on the surface.

For work, you must purchase a quality primer, which will strengthen the surface, and will not allow moisture to get into the connectors between the joints.

Process technology

The process of sealing plasterboard joints can be divided into several stages that even a novice master can handle. For inexperienced repairmen, it is important to remember to adhere to the rules. This is a particularly important point, since even minor violations can lead to poor results. Do not rush, it is important to do everything in stages.

Preparation of materials

No process can be completed without careful preparation. This also applies to seams.Initially, you need to know what should be the joints between the drywall sheets. The gap can be left small (approximately 1 - 2 mm). This is enough to ensure that the surface is not further deformed during shrinkage of the structure. With such an opportunity, only the seam will crack, and the sheets themselves will remain intact. On the face GKL, the gap needs to be made larger by expanding the distance between the sheets to 2 mm.

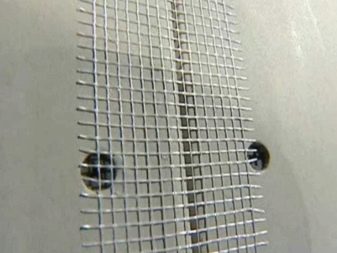

Next, you need to clean the surface of drywall from dust, cut off all the irregularities with a special knife. You can wipe the surface with a sponge or cleaning cloth. It will take a little time. Then will need to check the screw caps. This should be done in order to avoid staining when working with putty, when the spatula jumps on the self-tapping screw. To do this, you need to hold your hand on the attachment points. Screw caps should be screwed with a screwdriver or screwdriver.

Then you need to apply a layer of reinforcing primer. If it is a concentrate, it is necessary to dilute it with water in accordance with the proportions indicated on the package. It is enough to mix the prepared primer, after that it can immediately be smeared with seams. Apply it at a distance of not more than 15 cm from the joint.

The treated area is clearly visible on drywall, so the process is perfectly controlled.

Seam sealing

Having prepared all the surfaces, as well as having purchased the necessary materials and tools, you can begin to seal the slots. Previously, this process was very time consuming, it was necessary to apply a solution, embed a serpyanka tape in it. With the development of technology and the emergence of new building materials, the situation has changed for the better. Now serpyanka has a self-adhesive layer: this is already enough to significantly simplify the work.

The edge of the tape is easy to pick up and peel off. At this stage, you can not rush, so as not to spoil the whole work. It is necessary to slowly unscrew the tape layer, pressing it to the drywall joints or the opening between the sheet and the floor. Upon completion, it is enough to cut the ribbon with a special knife.

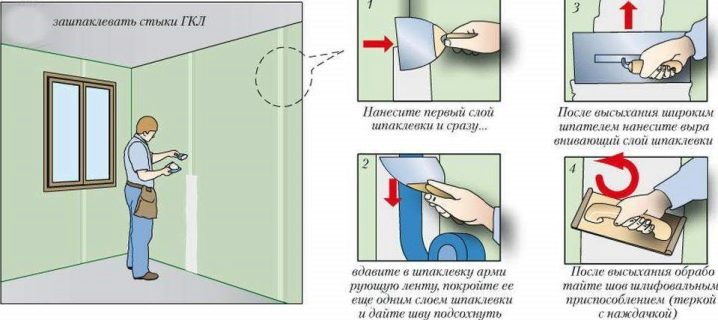

Upon completion of work with the tape, you must prepare the putty, using a drill with a special nozzle. The consistency of the solution should resemble thick sour cream. Next, using a spatula fill the entire space of the seams between the sheets GKL. Moving the spatula across the joint, you need to cover the seam, while pressing the solution into it. All this is repeated until all the sutures are filled. To align the plane of the joints with chamfer putty put a strip of 150 mm on each side.

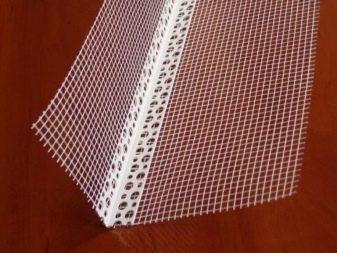

To strengthen the corners, you need to use a serpyak grid, whose width is 100 mm. This will avoid cracking in the most difficult areas. To work with corners does not take a lot of time, and the result was perfect, it is necessary to carry out work using an angular spatula. Cutting a piece of mesh of the desired length, you need to fold it in half and attach to the corner, then apply the solution on both sides and stretch it with a spatula. In this way, they close up the internal corners near the ceiling. For sealing external use metal corners, secured with screws.

When the surface is completely dry, it needs to be leveled using sandpaper. or special grinding machine. If irregularities are noticeable after grinding, a more thorough surface treatment is necessary, including leveling. This process is repeated until all problem areas are out of sight. Then drywall primer, using a special composition of deep penetration.

After the primer has dried, the plasterboard base can be considered ready for wallpapering or painting.

Tips

After examining all the stages of sealing seams, you can make them yourself. Do not rely solely on their own strength and do everything at random. Sealing the seams, you need to listen to the advice of experts. No matter how well all the work was done, problems may arise due to the high load on the walls or sudden changes in the weather. Worry about it is not worth it.

However, to prevent this from happening, you need to remember that when the temperature drops any material can be deformed. In the case of drywall, this leads to cracks. Therefore, you need as carefully as possible to fill the seams. Butt joints must necessarily have a chamfer: this will allow to better strengthen the structure of drywall.

Priming must be carried out using an acrylic mixture (mandatory for interior work), as the facade primer has many harmful substances. Its layer contains antifungal components. They save the walls from the appearance in the room of fungus or mold. It is recommended to use a compound with a greater penetration. This tool, on drying, forms a crystal lattice on the surface, due to which a subsequent layer of material applied to the drywall will adhere well to the base.

The choice of materials for the work should be treated responsibly. It depends on their quality how long the treated wall will stay. You can not buy material expired. In addition, it is important that the structure was of high quality and free of lumps. A bad foundation will not last long, you will have to re-carry out repairs.

Joints better handle perforated paper tape. She, too, must be of high quality. Barely noticeable on the basis of a micro-hole - this is exactly what prevents the tape from puffing up. Good tape prevents cracking.

Do not forget about the doorway or niche. To seal them, it is necessary to initially measure, and then cutting drywall. So there will be enough material for the entire scope of work, and the opening will be neat. It should be secured with self-tapping screws and filled with sound insulating material. After installation, you must put the perforated corners under the plaster and apply a serpyanka grid.Putty in this case is applied in two layers (each after drying the previous one).

Finally, it is worth recalling that plasterboard material for the bathroom must be moisture resistant. This will minimize the possible deformation.

Such drywall will withstand the temperature drop, as well as excessive humidity. The surface of drywall should additionally be treated with a quality primer (this will protect the material, it will last much longer). In addition, it is important to consider: it is impossible to seal the seams qualitatively if poor drywall is selected. His purchase should be carried out in a reputable store with a good reputation.

To learn how to properly seal the drywall seams, see below.