Volma hard putty: advantages and disadvantages

The Russian company Volma, which was founded in 1943, is a well-known manufacturer of building materials. Many years of experience, excellent quality and reliability are the indisputable advantages of all brand products. A special place is occupied by putty, serving as an excellent alternative to drywall sheets.

Special features

Volma putty is a high-quality material used to create a perfectly flat surface. It is made on the basis of gypsum or cement mixture, which is characterized by good viscosity.

Gypsum filler is dry. and is designed to align the walls manually.It also consists of other components, including chemical and mineral additives. The use of these additives is responsible for increased reliability, adhesion and excellent moisture retention. These characteristics provide fast and convenient work with material.

Due to fast drying, Volma putty allows leveling walls quickly and easily. It is often used for decorative interior decoration or used for outdoor work.

Benefits

Volma is a popular manufacturer, as the quality of its products is worth it. The company offers a wide range, including several types of mixtures.

All putty brand has the following advantages:

- Environmentally friendly product. Building material can be used to align the walls in different rooms, including a children's room. In its composition there are no harmful components.

- The mixture is air and plastic. Working with putty brings one pleasure, since the alignment is very quick and easy.

- The putty gives the surface a beautiful appearance.There is no need to additionally use the finishing mixture.

- After using the building material shrinkage is not carried out.

- The material is characterized by the ability to thermoregulate.

- To even the wall, it is enough to apply only one layer, which usually does not exceed a thickness of more than six centimeters.

- The material is characterized by the ability to thermoregulate.

- The mixture is durable, it also quickly hardens, which has a positive effect on the durability of the coating.

- The material can be used on various surfaces.

- The inexpensive price for dry mixes and the long shelf life allows them not only to select a budget option, but also to use the remnants of the mix in the future.

disadvantages

The Volma putty has some drawbacks that should be considered when working with it:

- In rooms with high humidity, you should not use a plaster mix for walls, since it does not have water-repellent properties. It should not be purchased for leveling surfaces in the bathroom or in the kitchen.

- Putty does not respond to sudden changes in temperature conditions.

- Gypsum mixes are unsuitable for outdoor work, as they very quickly absorb moisture, which results in flaking.

- Sanding walls should be done until they are completely dry, because after complete hardening the wall becomes very strong and unsuitable for grinding.

- The putty is presented in powder form, so before using it it is worth diluting with water. The prepared mixture should be used within 20–40 minutes, after which it will harden, and repeated dilution with water will only spoil the solution.

Species

The Volma company offers a wide choice of putties to create a perfectly smooth base, both indoors and outdoors. It offers two main varieties: plaster and cement. The first option is suitable solely for interior work, but the cement putty is the best solution for working outdoors.

Aquastandard

This version of the putty is cement, and additionally it consists of polymer and mineral additives. This type is characterized by moisture resistance, it does not shrink.

The mix "Akvastandart" is presented in gray color. It can be used at air temperatures from 5 to 30 degrees Celsius. When applying the mixture, the layer should not exceed the range from 3 to 8 mm The prepared solution should be used within two hours. High-quality drying is carried out in a day or 36 hours.

Mixture "Aquastandard" was developed specifically for leveling the base, which will later be painted or used for applying plaster. This variety is often used to eliminate cracks, grooves and gouges, but the allowable layer is only 6 mm. It can be used for internal and external work, as well as at low temperatures and high humidity.

Cement putty "Aquastandart" can be applied on different types of bases: foam and aerated concrete, cinder concrete, expanded clay concrete. It can be used to work with cement-sand or cement-lime surface.

The finish

The putty "Finish" is represented by a dry mixture. It is made on the basis of a gypsum binder component with the addition of modified additives and mineral fillers.This type is characterized by increased resistance to cracking.

Specifications:

- Work with the material can be performed at air temperature from 5 to 30 degrees Celsius.

- The drying of the coating takes about 5–7 hours at a temperature of 20 degrees Celsius.

- When applying the putty on the walls, the layer should be about 3 mm, and not exceed 5 mm.

- The prepared solution can be used for one hour.

Finishing putty is used for final finishing. Then you can paint the wall, glue the wallpaper or decorate it in another way. Plaster "Finish" is recommended to be applied on the prepared, previously dried basis. Experts advise using a primer before applying the putty.

The seam

This type of material is based on a gypsum binder component. It comes in the form of a dry solution that must be diluted with water before use. The composition of the filler "seam" includes mineral and chemical fillers of excellent quality. Increased adhesion of the material allows even to retain water.It is ideal for leveling work.

Main characteristics:

- When working with a mixture of air temperature should be in the range of 5 to 30 degrees Celsius.

- The base dries completely after 24 hours.

- When applying putty worth making a layer of no more than 3 mm.

- After dilution, the material can be used for the entire 40 minutes.

- The putty bag has a weight of 25 kg.

Putty "Seam" is ideal for sealing seams and flaws. Its peculiarity lies in the fact that it is able to cope with irregularities up to 5 mm deep. It can be applied to surfaces of various kinds.

Standard

This type of putty is represented by a dry mixture made from astringent gypsum, modifying additives and mineral fillers. The advantage of the material is increased adhesion and resistance to cracking. It can be used as a starting point when leveling.

"Standard" is designed for basic alignment of walls and ceilings. It is recommended to be used exclusively for interior work in dry rooms. The material will allow you to create a reliable and smooth base ready for painting,sticking wallpaper or other decorative decoration.

When working with standard putty, consider its technical characteristics:

- At an air temperature of 20 degrees, the material dries completely after a day.

- The prepared solution becomes unusable 2 hours after creation.

- The material should be applied in thin layers up to about 3 mm, the maximum thickness is 8 mm.

Polyphine

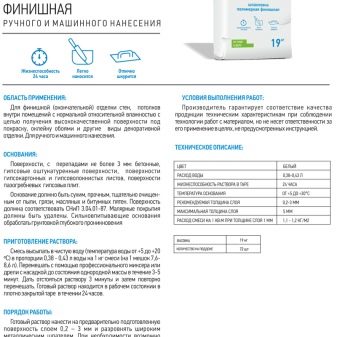

This putty is polymeric and opaque, ideal for creating a topcoat. It is characterized by high whiteness and superplasticity. Compared with other polymer putty brand, this type acts as the most technologically advanced.

To prepare a solution for one kilogram of dry mix, you must take up to 400 ml of water. The prepared solution in the container can be stored for 72 hours. When applying the mixture on the basis of the layer thickness should be up to 3 mm, while the maximum allowable thickness is only 5 mm.

"Polyphin" is designed for finishing various surfaces, but the work should be done exclusively indoors, as well as at normal humidity.You should not purchase this option for finishing the bathroom or kitchen.

"Polyphin" allows you to create a smooth and snow-white surface for wallpaper, paint or other decorative decoration. He skins great. Ready solution is available for use in containers for 24 hours.

Putty "Polyphin" is designed to work in dry areas. When applied, the air temperature should be between 5 and 30 degrees, and the humidity should not exceed 80 percent. It is preferable to use stainless steel tools when working with the mixture. Before applying the putty, it is necessary to make a priming, and at the same time the roller must be squeezed very well to avoid soaking the putty after applying it on such a wall.

Polymyx

One of the new products of Volma is a putty called Polymyx, designed to create the maximum snow-white finish alignment of the bases for further decorative design. This material can be used for both manual and machine application. The filler attracts attention with plasticity, which has a positive effect on the ease of application.

Reviews

The Volma putty is in high demand and has a well-deserved reputation. Not only consumers, but even construction professionals prefer Volma products, as they are of high quality and relatively low price.

The manufacturer allows the alignment of surfaces using its products independently. Each package provides a detailed description of the work with the putty. If you follow the described recommendations, then the result will pleasantly surprise you.

All mixtures of Volma are soft and uniform, which has a positive effect on the application process.

The putty dries quickly enough, while securely fixed with a base. Indisputable advantages of materials is reliability and durability. The company follows the quality and also seeks to provide the best product at an affordable price.

In the next video you will find instructions on the use of putty "VOLMA-Polyfin."