Finishing plaster: purpose and types

In the process of construction or repair to create a smooth surface of the walls for painting or sticking with any type of wallpaper, it is desirable to use finishing plaster. This type of building material, in contrast to the materials used at the initial stage, is particularly fine-grained. It is this property that allows you to end up with an ideally flat surface, on which it will be quite easy to place any decorative facing materials later on.

Application area

All types of finishing putty, depending on the application, can be divided into two main types:

- for outdoor work;

- for interior work.

This division is indeed conditional, since in all types of finishing works, identical mixtures are used, the compositions of which differ only in the addition of improving components, which in most cases are necessary for carrying out exterior finishing works. For facade solutions, it is necessary to increase the frost resistance and hydrophobicity of the putty.

The main functional differences of finishing plasters can be designated as:

- creating an ideal surface for decorating walls for interior decoration;

- protection from wind and moisture, the functions of insulation and decorative finishing layer for exterior decoration of buildings.

For exterior facade work, you can use compositions based on cement or polymer-acrylic blends.

The final choice will depend on what the main requirements for the finishing solution will be presented in each case. So, for wall insulation it would be advisable to use a sand-cement mixture with the addition of special components that improve ductility, and to protect against moisture and wind the best option would be a polymer mixture with an acrylic base.

Types of mixtures

There are several types of finishing putty:

- Cement plaster. This type of building mixture can be of two types, namely: cement-sand or cement-lime mixture. These building solutions can be used in rooms with high humidity and places of high mechanical load. The main and extremely unpleasant disadvantage of cement-based putty is the appearance of cracks over time. Therefore, you should not use it as a basis for painting.

- Gypsum plaster. This type of finishing mix is an excellent option when working indoors, it, unlike cement plasters, is not subject to the formation of cracks and is also quite resistant to mechanical stress. The main disadvantage of this material is that it is not moisture-resistant, therefore it is absolutely impossible to use it in outdoor work, as well as in rooms with high humidity.

- Polymer plaster. This type of finishing mortar has unique properties that can cope with any tasks. With the help of various additives it is possible to adjust the parameters of the finishing mixture.The most popular of all types of polymer mixtures is acrylic plaster.

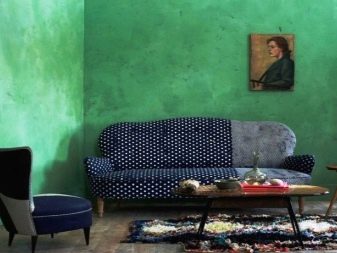

Decorative trim

Ordinary finishing plaster can be replaced with decorative putty, creating an unusually spectacular design of the walls in the room. There are types of decorative finishing plaster that can give a finished aesthetic appearance after application. Their use will allow you to create original textural effects with a variety of patterns.

The types of such putties include the following types:

- Structural mixture, which includes a variety of additional particles, for example, small pebbles, mica or quartz;

- Relief mixture It contains particles of marble chips, which, when dried, create the effect of broken glass, shimmering in the sun with all the colors of the rainbow. This type of finish is perfectly combined with other finishing materials;

- Textured putty - mortar with heterogeneous structure, containing in its composition a variety of additives. One of the most popular types of this type is the Bark Barker finishing putty;

- Terrasitic mixture - The basis of this type of finishing material is white cement with the addition of small particles of sand, mica, lime, glass and other additional components;

- Putty "Floki" - Matte finish coating of acrylic flakes of different sizes and shades, this type of finish requires additional coating with acrylic varnish.

Tips for choosing

The result of the finish will depend on the correct choice of finishing putty, its structure and consistency, as well as on strict adherence to the technological process - that is, ideally smooth surface of the walls, floor or ceiling.

For finishing work indoors, one of the best building structures is the finishing plaster "Pitfalls" on a plaster basis. This type of putty is perfect for leveling both concrete and brick walls, it can also be applied to drywall in rooms with a moderate level of humidity. Apart from the fact that the plaster castors “Prospectors” are ideal for removing cracks on any surfaces and pouring joints between concrete slabs, it is commonly used as a finishing material for walls.

The putty owes its extraordinary popularity to the excellent quality of the product, as well as the price available to the buyer with any budget level.

The putty, produced on the basis of gypsum, contains in its admixture a variety of modified additives and components, giving it a special plasticity.

The ready-made “miners” solution has many remarkable properties:

- the ready mixture is applied to the surface easily and evenly;

- the possibility of applying a layer of five to fifty millimeters in one pass;

- the ability to increase the thickness of the layer to eighty millimeters in some small areas;

- high elasticity of the material prevents the formation of cracks when the plaster dries;

- a good level of vapor permeability will ensure sufficient moisture penetration into the room with dry air. And in rooms with high humidity, building mixture, on the contrary, will delay excessive vapors, providing an optimally comfortable indoor microclimate throughout the entire time.

Finishing tools

To process the walls with a finishing putty, you need to stock up with the necessary tools that you will need in the process.

These include the following set:

- industrial mixer or ordinary construction drill with a special nozzle - this tool is necessary for thorough mixing of the dry mixture with water in certain proportions;

- plastic capacity, suitable in volume, for dilution of the desired amount of finishing putty;

- spatula of suitable size for direct application of the finished mixture to the surface. It is best to purchase a building kit consisting of spatulas of various sizes. It is convenient to work with large trowel on large open surfaces, but in hard-to-reach places you will certainly need a more miniature tool;

- wide brushes or rollers for priming the surface. This procedure is necessary to cover the walls with a protective layer. The primer further has a beneficial effect on strength and adhesion when working with any facing materials;

- emery paper and skinner are necessary for leveling irregularities, removing small particles of solidified mixture. When working with a finishing putty, it is desirable to use fine sandpaper;

- the construction level will be needed to test the surface for perfect evenness.

The process of applying the finishing putty, see the following video.