Choosing a countertop under the sink for the bathroom

Presently in bathrooms the set of design decisions is embodied. The room for hygienic procedures has become a sophisticated place with maximum functionality and amenities. For even more comfortable use of bathrooms, it is necessary to choose a high-quality countertop under the sink.

Special features

Instead, the cabinets under the sink or the usual shelves today is set to a horizontal surface that can be used as a large table. It can accommodate all the necessary accessories for their own hygiene. A sink and a faucet are harmoniously built into the surface. A washing machine, a laundry basket and practical drawers for towels or other things are quietly placed under the table top.

When choosing, you must first pay attention to the room in which the table top is installed. The constant influence of steam, water, high humidity and temperature changes creates specific requirements for the materials from which it should be made. Therefore, when choosing a tabletop, one must take into account not only the decorative and aesthetic parameters, but also the features for caring for it, as well as the functional properties of the product.

In addition, it must be remembered that the working surface of the countertop with a washbasin during continuous operation will be exposed to various cleaning and detergents.

Kinds

The countertop in the bathroom is also a separate element of the interior. They differ from each other in their configuration, size and dimensions, the materials from which they are made, as well as the method of fastening. Sometimes several sinks can be placed on the same tabletop. They can be angular, multi-level and with various interior bends.

An important nuance when mounting worktops is the fastening of the structure.

According to the method of fastening tabletops are divided into three types.

- Overhead.Mounted on the floor using supports or legs, like a table or nightstand.

- Suspended. Suspended to the wall with special strong brackets.

- Semi-suspended. One side is suspended to the wall as in the suspended mounting option, and the second is mounted on the floor, as in the surface mounting option.

According to the design tabletops are also divided into three types.

- Solid - this is the tabletop, which with the sink are one. This tabletop is not collapsible.

- With built-in sink. In the countertop is cut a hole to the size of the embedded shell.

- With counter basin. On top of the countertop mounted invoice sink, which can be easily replaced if necessary.

You can mount a round sink or in the form of a bowl.

Materials

Today, manufacturers of bathroom furniture use a variety of high-tech equipment and the latest technology, so they can offer countertops made of various materials.

A natural stone

Suitable for those who are important quality and decent appearance. This tabletop looks very noble and expensive. It has considerable weight.It is also worth noting that the cut pattern of a stone on such a tabletop will never be repeated anywhere, since it is unique. Its main advantages are heat resistance, durability, wear resistance. This surface is almost impossible to damage, and if scratches are formed, they can be easily polished. The disadvantages of this material include a large weight of the product, high cost, difficulty in installation and processing.

Basically, for the manufacture of countertops using marble and granite. Much less - quartz, onyx and gabbro (frozen magma). The installation of such a tabletop, as a rule, costs one third of the cost of the product itself, and it is unlikely that you will be able to install such an item of interior yourself.

Fake diamond

It looks no worse than natural, while the choice of colors and various decorative solutions is much wider than that of natural stone. The design itself in comparison with the natural counterpart is slightly lighter in weight.

Divided into two types.

- Acrylic stone, which is the most common material in the production of countertops. Consists of acrylic resin, mineral chips and various colored pigments.The main advantages of this stone are maintainability, the ability to manufacture complex shapes, ease of care, the cost is much lower than natural stone, invisible joints. Disadvantages: low strength, stains from acids and paints, low heat resistance, difficulty in installation and processing.

- Quartz agglomerate. It consists of quartz, granite or marble chips, polyester resin and various additives and dyes. It is produced using high pressure, which gives the material excellent strength. This stone should highlight the following advantages: durability, heat resistance, ease of maintenance. Disadvantages: not repaired, complexity in installation and processing, large weight, high cost compared to acrylic stone, there is no possibility of making complex structures.

Natural wood

Countertops under the sink for bathrooms are made of three types of wood: oak, larch, teak. Manufacturers also offer countertops, glued together from pieces of various tree species and soaked with moisture-resistant liquids. In any case, these surfaces need to be covered with more than one layer of special varnish.

The advantages of wood: ease of installation and processing, the possibility of making complex shapes. Disadvantages: low strength, dubious durability.

Glass

The glass worktop is versatile, since glass, especially transparent, will fit almost any interior.

There are also:

- Frosted glass countertops - they are most popular because they do not cast shadows, cover the contents under the tabletop and there are almost no scratches on them;

- optical glass worktops - equipped with LED lighting, which creates a beautiful lighting effect around;

- products from colored glass with patterns and unique appearance - they are created from several layers, each of which can be of a different color, with beautiful drawings, and also have 3D effects;

- tinted - made of special thermally tempered glass or tinted with a film on the inner side of the surface;

- mirror - extremely rarely used because of the fact that any defects and even insignificant drops of water and fingerprints are perfectly visible on the surface.

Despite its fragile appearance,glass countertops are strong enough and not so easy to break. The advantages of glass tabletops: ease of maintenance, heat resistance, durability, low cost. Disadvantages: brittleness during installation, processing and operation.

MDF and chipboard

Many are skeptical of countertops made from these materials, to put it mildly. But because of their low cost and ease of installation, they are popular. Panels for tabletops of this type are made from wood scraps and sawdust. To a chipboard add the toxic gluing structure. MDF is produced using high pressure. At the moment of strong compression, a substance that is the adhesive base is released from the crushed wood. The plates are covered with a special moisture-resistant film, which provides ample opportunities in the choice of colors and various patterns.

Advantages: low weight, easy installation and processing, easy maintenance, low cost, fast production time. Disadvantages: short service life, low strength.

Drywall

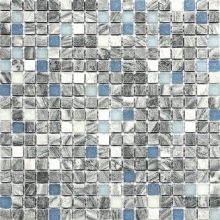

This method of manufacture is used in the decoration of the working surface of the countertop tile or mosaic.To do this, use a galvanized profile, so as not to rust, and moisture-resistant drywall. This technology allows you to make any form of table top. After it is ready, ceramic tiles or mosaics are laid on it.

Caring for such a countertop is the same as for ceramic tiles. Advantages: versatility, durability, easy care. Disadvantages: complex installation and disassembly.

Plastic

Plastic tops are light and durable, have different colors and shades, as well as low cost. Advantages: plasticity, durability, easy care. Disadvantages: low strength, low temperature resistance.

Dimensions

The parameters and dimensions of the countertops under the sink for the bathroom depend on the following indicators:

- the size of the room itself in which the installation is planned;

- value, for example, the width and shape of the shell (or sinks, if there is more than one);

- the way it / their installation;

- material from which the table top will be made.

Glass tops have more graceful and thin forms. Models from a natural and artificial stone, from gypsum cardboard and a natural tree will be more massive and bulky.Countertops made of MDF and chipboard will have average dimensions, something between glass and stone products.

Manufacturers Overview

To date, there are many manufacturers of countertops under the sink for the bathroom, so choose a decent sample will not be difficult. The main thing is to decide on the choice of material from which the surface will be made, to discuss the timing, size and cost.

You need to pay attention to the fact that products made of natural stone are made to order for a long time, and if you are offered a short production time, you should think. You can also get acquainted with the assortment of ready-made proposals from large stores that sell goods for repair and interior.

Among the manufacturers can be identified:

- Vitra. This is a company from Turkey, which in 2011 took a risk and offered cooperation to the designer from Russia - Dima Loginov. Designer countertops made of ceramics of his authorship is very popular. Over the seven years of cooperation, several collections have been created.

- Ceramica Bardelli. This is a newcomer to the production of sink tops.This company recently began to attract to the development of their own collections of both eminent and unknown designers. Ceramica Bardelli manufactures products based on sketches by the famous Piero Fornasetti, professional Luca Scacchetti, innovator Torda Buntier, Joe Ponty and others.

- Pamesa The company is engaged in production under the logo of the Spanish designer Agatha Ruiz de la Prada. A distinctive feature of this brand is expressive, dazzling, poisonous colors.

How to choose?

Countertop sinks - this is a fairly new solution in the interior of bathrooms. The advantages of these countertops are that instead of various cabinets and shelves you now have at your disposal a whole table on which you can store many accessories. Under the table top you can put a washing machine and any design with drawers.

The operation of this countertop is significantly different from the operation of the kitchen. In the kitchen more aggressive factors, for example, mechanical or high temperature effects. The bathroom does not usually cut vegetables, do not discourage meat and do not put hot pans on the surface.The main factors of negative impact here are high humidity and constant contact with water and various detergents.

The most durable and durable stone. A quality product will last for decades. When choosing this material, you need to take into account its large weight, high cost and quite a long production process.

The artificial stone practically does not concede natural in durability and durability, at the same time having lower cost. It also attracts a huge selection of color and graphic solutions for countertops made from this material.

Choosing an artificial stone you should know that on an acrylic stone, if the tabletop consists of several parts, you can remove all the seams and joints, giving the surface a monolith appearance. But on the quartz agglomerate, which is produced only in the form of tiles of a certain size, it will not work.

The best option can be a glass countertop. With their average cost, you can get an aesthetic appearance of the bathroom and good strength and durability of the product. This design will harmoniously fit into the bathroom of any size.This type of products is made of tempered glass or laminated plexiglass. When it is broken, tempered glass crumbles into small cubes with edges that are hard to cut, and when plexiglass is laminated, it becomes cracked when damaged, but it does not crumble into pieces due to the film between the layers of glass.

Even in emergency cases, glass products are practically safe for humans.

The tabletop under the sink for a bathroom of plasterboard - the choice of people who know how to make a beautiful interior with their own hands or want to realize their design project, but manufacturers of standard countertops are not taken for it. Also, with the help of this design it is possible to beat various disadvantages of the room.

The cost of the construction itself is relatively low, the final price will depend on the tile or mosaic chosen for the final finish, and the size of the product.

A wooden countertop will fill the bathroom with warmth emanating from natural wood, and the elegance with which a wooden product fits into the design of tile and metal is incomparable to anything else. But when choosing such a tabletop you should not forget thatthat this material requires careful maintenance, and the tree itself in comparison with other materials for tabletops is quite soft, susceptible to deformation and moisture absorption.

It is desirable that good ventilation is installed in the room with a product of this kind and moisture does not accumulate.

The worktop of MDF or particleboard today is not only one of the budget options, but also the most short-lived product for bathrooms. Despite the fact that manufacturers declare moisture-proof materials used in the manufacture of tabletops, practice shows that the service life of such products is much lower than that of all others.

Choosing a chipboard tabletop, you need to remember that the composition of which the tabletop is made can be toxic. The fact is that the adhesive used in the production of panels emits formaldehyde, which is dangerous to human health. Therefore, pay attention to the index E specified in the documentation for the product. If it is zero or one, then this material can be used at home.

Plastic table top is the most budget option and has a corresponding appearance.Choosing plastic you need to remember that it can be toxic.

How to make yourself?

Not all types of countertops can be made independently. The surface of any stone and glass requires processing on special equipment and the application of certain skills and knowledge. To date, the countertop under the bathroom sink can be independently made of wood and drywall.

In the manufacture of wood tops we need a wooden plate to the size of the tabletop, moisture resistant impregnation for wooden coatings, sealant for seams, tools. To begin with, we remove all the dimensions in the place where the tabletop will be installed, think over the method of attachment. From a wooden blank with an electric jigsaw cut the tabletop, using the dimensions and shapes, taken in advance in the bathroom.

After that, in the resulting tabletop, we make a hole for the siphon, if the shell is invoice, or cut a hole for the sink, if it is embedded. A hole is also made for the tap in its diameter if it is to be mounted on the tabletop, and not on the wall. If the tabletop will have two or more sinks, then cut holes for all the elements.At the same time, it is necessary to make in advance all the necessary holes for fastening the table top to the wall and / or floor, depending on its design.

When the shape of the table top is ready and all the necessary holes are made, proceed to the processing of the edges. For this we need sandpaper and a special machine. After processing, the entire surface of the worktop must be smooth and even. After finishing the edges and holes, proceed to the coating of the wood and all its ends with a moisture-resistant composition in accordance with the instructions on the package. The next stage is varnishing, also according to the manufacturer's instructions. Moisture-resistant composition and varnish is desirable to apply in several layers.

Do not forget about the ends, edges and holes. There, too, you need to process everything qualitatively. After complete drying of the deposited products, the tabletop is ready for assembly. In this case, all the joints adjacent to the table top, the walls of the sink and faucet, must be treated with sealant. This will eliminate the ingress and stagnation of moisture in hard to reach places.

The technology of self-manufacturing countertops made of MDF or chipboard practically does not differ from the version with wood.Do not need varnish, moisture-resistant composition and sandpaper processing. But if in the project of the table top there are rounded corners, then after cutting, the ends of such corners will need to be glued with a special film. Independently it will not work.

That is why the complex configuration of the MDF or chipboard tabletop with all the holes and bends in accordance with the project is better to immediately order the manufacturer of such products.

Making the tabletop out of drywall is a more complicated process, but it also gives you more opportunities to make curved, rounded, and other unusual forms of construction. We will need moisture resistant drywall. It is sold in ready-made sheets. Their number is calculated from the size of the conceived tabletop and multiplied by two, since the base is made in two layers.

We also need a profile, always galvanized. It will be used in all the supporting structures of the conceived tabletop, and already drywall will be attached to it. Accordingly, the amount of profile depends on the size and configuration of the project. If bends are designed on the surface of the product, then it is best to purchase flexible drywall for arches.You will also need metal screws, glue for gluing plasterboard sheets, tile glue, tile or mosaic, moisture-proof sealant, joint sealant.

If a curved product design is planned, then only a mosaic will be suitable as a facing.

When everything is ready for work, then proceed to the manufacture of the product. Having defined the height at which the table top will be located, draw a horizontal line and fasten the cut profile to the wall. If the structure has several levels in height, then fasten profiles to the wall in accordance with the intended structure. After that, also from profiles we collect the frame of our future table. This type of tabletop can not be suspended, so do not forget to make supports. When the frame is assembled, we sheathe it with sheets of drywall.

It should be noted that the drywall itself will not last for a long time under the constant influence of moisture, so the more high-quality and airtight the tile or mosaic will be laid, the longer the assembled construction will last. A tile or mosaic not only creates a beautiful appearance, but also protects the table from moisture.

After the frame is sheathed with plasterboard and all the necessary holes are cut, we begin the lining with tiles or mosaics. The technology of laying tiles is the same as for walls and floors. When the tile or mosaic is laid, and all seams are treated with sealant, we mount the sink, tap and siphon, connect all communications.

How to make a tabletop under the sink of drywall, see the following video.

Installation Tips

When installing the structure under the sink in the bathroom, it is necessary to take into account its weight and method of attachment. Suspended structures represent the greatest danger, so you need to pay attention not only to the fastening of the tabletop, but also to the strength of the wall to which they will be attached. The mounting bracket itself must be made of steel with an angular or square profile.

If the tabletop is heavy, then the bracket must be diagonal reinforcement. This bracket has the form of a triangle. You can also use brackets in the form of squares or rectangles. The bottom crossbar of such an arm can be used as an additional hanger for towels and similar things.

If the construction is laid on and installed on supports or legs, then it must additionally be attached to the wall, which will exclude its shifts in different directions.

All joints and places of moisture accumulation must necessarily be treated with a moisture-resistant polyurethane sealant. In the manufacture and installation of drywall worktops do not forget to leave the possibility of access to pipes and cranes for the implementation of their maintenance, repair or replacement. Otherwise, in the event of an emergency, you will have to destroy the fruits of your labor, and then spend time and money on restoration.

You need to properly produce fasteners design, so that it will serve you for many years. You can embed it from the bottom or stick it on top. Do not forget to carefully seal the gap.

Beautiful design ideas

- A design from a natural tic. Effectively and harmoniously fits into the interior of the bathroom, creating a pleasant contrast and giving warm colors to the atmosphere of the room.

- The construction of natural stone evokes a feeling of luxury and speaks of good taste. Natural colors and soothing tones add statism.This is the only instance in the world, because there are no identical stones in nature.

- Construction of drywall. Great solution for a small bathroom. The product is compact and neatly fit into the space of the room, giving it additional functionality.