How to choose a bracket for the sink?

The interior of the bathroom provides for the availability of sanitary equipment with an optimal position in space. Depending on this, each shell model involves a specific method of attachment. Among the latter, brackets are gaining popularity, with the help of which it is easy to hang a sink on a wall.

Special features

Fastening with brackets connects the sink with the wall surface. Products securely hold the design, despite the heavy weight. Depending on this, the brackets differ in many characteristics: form, method of attachment, structure and materials of manufacture.Also, the consumer can choose an individual design suitable for home interior.

The mounting system can be installed on any surface:

- brick;

- drywall;

- wooden;

- concrete.

Due to the high technical characteristics of the brackets are resistant to mechanical damage. Products are designed to hold any mass and shape.

Even stone sinks will be securely fastened to the wall.

When fixing the shell using the suspension system, some nuances should be taken into account.

- It is advisable not to install heavy sinks on “soft” walls. The base in the bathroom should be reliable and thick. For example, plasterboard walls are not suitable for the installation of large sinks because they require additional anchors of at least 40 mm in length.

- Materials for the manufacture of brackets give a certain rigidity. In accordance with this parameter is determined by the weight of the supporting structure. Brackets with a width of 240 mm or 260 mm are not able to withstand ceramic washbasins, for which fixings of 32 cm are necessary. Metal products withstand brackets of 300 mm, 320 mm and 360 mm.

- When buying brackets you should consider their design. In some cases, the shape and size of the attachment does not correspond to the place of adhesion to the plumbing.

Installation can be easily carried out on its own. This feature increases the demand for brackets in the building materials market. However, in addition to the advantages, the details have serious disadvantages.

For example, an inclined sink will have to be dismantled and then reinstalled. Also, the brackets are not adjustable.

In addition, durable parts strongly “hit the wallet”, without having budgetary analogues with the same technical characteristics.

Mounts

The suspended structure has become an everyday accessory in the bathroom. Over a long period of operation of the sinks, many types of brackets have been created, which differ in structure, parameters and maximum allowable weight.

Depending on the features of operation and technical characteristics of the brackets are divided into the following types:

- specialized;

- standard;

- designer

The latter are distinguished by the highest price in the market due to the factthat in most cases they are given an individual decorative form for the design of a particular bathroom. They are made to order.

Regarding the type of production material there are several types of fasteners.

- Steel brackets. Fastenings of this look are made by a welded method. The result is a single design, having the form of the letter "G" or "T". Low cost options are made of shaped tubes. Such brackets have a simple structure and a short period of operation.

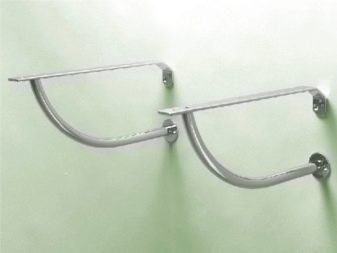

- By the type of profiled steel frame, it is possible to make a grasping bracket, which is then attached to the wall. A sink is installed on the arc-shaped base. This category of brackets is the most durable. The platform is securely fastened to the wall, eliminating the possibility of displacement or damage to the sink.

- There are brackets made of cast iron cast method. They have an elongated solid base, which is based on a sturdy platform, forming a monolithic structure. Cast iron bracket resembles the letter "T".

- For installation of sinks with non-standard parameters, metal brackets are used: sector,rectangular and arc-shaped. Some designs are equipped with sliding type nodes.

- The material for the manufacture can also serve as chrome. Such brackets in most cases have a persistent matte color.

The nuances of choice

Fixing the sink on the wall is not complete without brackets. To ensure long-term and convenient operation is possible if you have the appropriate knowledge about them.

Details are divided into standard and specialized. The latter are made together with a decorative sink, which is why they do not have to be selected separately in the construction market.

Specialized brackets may have a florid shape that fits the washbasin style. The ceramic anti-corrosive agent takes over the anti-corrosion protection function. In most cases, nickel and anodized coating is used.

Standard fasteners are made from cast iron and steel intended for welding. Materials for the production of a protective layer of coloring matter.

When choosing brackets of a standard type, it is necessary to take into account technical specifications and recommendations from the manufacturer.At a certain shell weight, an annotation should indicate a weight greater than its mass.

Do not forget that in some cases, people rely on the sink. And this is a few extra pounds, increasing the load on the attachment.

Therefore, when choosing fasteners for the sink, you should acquire structures that are able to withstand a load greater than the expected weight.

For example, in the case of purchasing a shell weighing 70 kg, you should buy fasteners designed for a weight of 90 kg.

Installation Tips

Abstract installation of shells with special mounting systems is quite simple. Following the instructions, the apartment owner can easily install the washbasin in the suspended position.

From the tools you will need:

- perforator;

- measuring tape;

- hammer;

- marker.

The drill for the perforator is selected depending on the dowels with plastic cores that fit the brackets. To mount the fasteners as smoothly as possible, you will need a water level and a pencil to create marks.

For the work should proceed from some of the recommendations.

- If the wall is not strong enough, it is recommended to reinforce it with cement mortar before starting work, otherwise the mount may fall under the weight of the sink.

- At the first stage, 85 cm are measured from the floor. Due to this, the sink will be located at a level of up to 90 cm. In a family with small people, these parameters are reduced.

- Also measure the distance between the mounting holes on the side of the sink that will be attached to the wall. Using a pencil and water level, make appropriate marks on the wall. Also before drilling it is necessary to make sure that the acquired brackets fit the specific model of the sink.

- Holes in the wall should be similar to the diameter of the plastic cores dowels.

When drilling it is necessary to keep the punch in a clearly horizontal position. In the case of moving from side to side, the hole will be too wide.

Then the brackets will not be able to securely hold the sink. For a more dense attachment, you can make a mark on a drill punch with a marker for 1.25 of the length of the plastic core.

In case of installation of brackets on plasterboard walls, wooden chopik should be used, replacing the plastic nozzle from the dowels. Their diameter must exceed the diameter of the hole.

To learn how to make your own brackets for washing, see the video below.