Bellows water liner: what it is and why it is needed

Even 20-25 years ago, in order to connect a washing machine, the work of welders was required to build water supply. Appearing later, the flexible wiring significantly simplified the connection of various appliances and plumbing, but increased the risk of leakage. To date, appeared on sale bellows liner allows you to solve all these problems at once.

What it is?

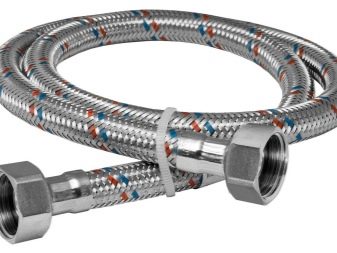

Bellows are made in the form of a stainless steel corrugated hose for supplying or discharging water. However, this type of eyeliner is used to supply not only water, but also gas. Compared to rubber hoses, the flexibility of the bellows hose is somewhat lower, although it is a stretch corrugation.These products are presented on the market in a variety of ways, differing in color, price, size and service life. In recent years, they have almost supplanted metal pipes and are used for sinks, showers, cisterns, washing machines, water heaters, air conditioners, and more.

Advantages and disadvantages

Each material and equipment has its own advantages and disadvantages. The strengths of the bellows are:

- high quality stainless material;

- eyeliner is not destroyed by water hammer;

- long service life due to the reliability of the design;

- not afraid of a sharp decrease in temperature;

- made of hygienic material and does not pose a threat to health;

- steel is not combustible;

- able to supply water up to 250 degrees Celsius.

Unfortunately, even such a universal material has its drawbacks:

- the flow of water inside the corrugated metal creates a perceptible noise, especially when several water consumers are turned on;

- The bellows is not as flexible as a rubber or rubber metal hose;

- high cost of liner

Increasing noise and vibration can be avoided by using larger hoses or with a plastic sleeve.

Characteristics and dimensions

The liner is made of steel with brand AISI304 in the form of corrugated pipes of various lengths with cap-shaped, seamed nuts at the ends. The wall thickness of such an eyeliner is 0.3 mm and more, depending on the manufacturer's documentation and production standards. During the production process, a steel pipe can be additionally processed by a vacuum-heat method inside a furnace with a temperature of from 1020 to 1100 degrees Celsius in order to give the metal such property as flexibility. Hexagon cap nuts (fittings) with a half-inch female thread are attached to the ends of the hose by flaring the edges without welding. The presence of such nuts eliminates twisting of the sleeve during installation. The pressure in the installed bellows is from 10 to 16 atmospheres and depends on the type and material of the gaskets used, which compress the connection.

The corrugation is covered with an additional polymeric material that protects the metal from corrosion and exposure to high temperatures, and also helps to avoid contact with the structures that conduct current.Corrugated with stainless steel or brass nuts guarantee the absence of cracks and corrosion in the joints and a service life of up to 30-35 years. The eyeliner is tested for the presence of microcracks with the help of helium, and for the symmetry of the coils with the help of metallographic examination. The fitting can indicate the country of manufacture or a specific factory, the type of hose, and even the date of its manufacture. The package may additionally include special pads for the connection and various documentation.

Sizes bellows liner can vary in a sufficiently large range, ranging from very small hoses and ending with meter tubes. Available in two types of bellows:

- with a fixed length (20 cm, 30 cm, 40 cm, 50 cm, 60 cm, 70 cm, and 80 cm);

- folding (for this type of liner indicates the range of values from minimum to maximum 140-250 mm, 200-350 mm).

The coupling diameters of the flare nuts can be 1⁄2, 3⁄4, 1 inch, 11/4, 11/2 and 2 inches with an allowable pressure ranging from 10 bar to 20 bar, depending on which gasket is used. The corrugated pipe is quite flexible and maintains permeability even with full bending, thereby ensuring uninterrupted operation of the entire system.Connections at the ends of the hose can be fastened with a nut-fitting, nut-nut or fitting-fitting system.

Materials

Materials for the manufacture of bellows liner differ depending on what substance will be carried out through the pipe.

Bellows for water

This liner is made of stainless steel AISI 316 brands, to which are welded nuts or fittings of more rigid steel AISI 304 or AISI 303. Copper, plastic, rubber or aluminum gasket fits into the pipe connection. Some manufacturers make choke or nut using carbon steel. However, the use of an eyeliner with steel of different grades is not recommended, since the corrosion of the material occurs faster at the welding point. In some cases, the manufacturer may solder the fittings with tin or even glue, which also reduces the strength and durability of the product.

Bellows for gas

This seamless corrugated pipe is also made of steel, but coated with PVC in various colors. Such a shell protects the flexible connection from aggressive media, prevents gas leakage and serves for additional electrical insulation.In case the eyeliner has passed the firing treatment, it can be stretched in length up to two times.

Purpose

Flexible bellows liner allows you to replace the pipeline section where it is impossible to install rigid structures. It is used to connect faucets and various plumbing equipment (for example, a washing machine, toilet and bath). The bellows is used to supply gas to heating systems, gas stoves and water heaters. With this connection, you can connect various climatic equipment and automatic fire extinguishing systems or compressors. Bellows liner is often used in large industrial enterprises to supply steam, petroleum products, chemical solutions, and even bulk solids.

When working with flexible types of liner it is necessary to follow certain recommendations. Do not allow a bend radius smaller than allowed in the documentation. Do not bend at the ends closer than the distance specified in the documentation. Do not twist the hoses, repeated bends and excessive stretching., as this may lead to breaks and cracks.One of the most important recommendations is not to overtighten the nuts when tightening, so as not to damage the gaskets and not to break the thread. Damaged liners are not repaired, but are completely replaced by new ones.

Manufacturers

Today, the bellows can be purchased from both domestic and foreign manufacturers. One of the main Russian manufacturers is the company. "Monolith"registered trademark "Monoflex". The quality of the products of this company is guaranteed by foreign technologies used in the production process. Also established products under brands "Aquatekhnika" and Flexilein.

Also, the budget option bellows company offers Zurflex from Belarus. At a reasonable price, the quality of the products of this brand can be compared with large European manufacturers, for example, a German company. Witzenmann. The traditional quality and reliability of products of this company, located in Germany, is represented not only in bellows wiring, but also in other types of various plumbing equipment.

One of the leading suppliers of water entries at the moment is Turkishcompany Ayvaz, the equipment of which practically has no competitors in technical parameters. Their wiring is reliable, durable, and has a well-thought-out design that excludes unnecessary items. On the flexible gas supply market, Italian companies are the undisputed leader. Emiflex and Idrosapiens. The bellows hoses of these companies in Russia are certified by Rostest and Gosgortekhnadzor. The service life of such connections is up to 15 years and above.

Often in the market under the logos of world brands you can buy a fake from China. There are two categories of Chinese equipment:

- products manufactured in China by the official order of European companies;

- wiring made by piracy.

In the first case, the digging customer transfers production to China to reduce costs due to cheap labor and materials. In the second case, the product quality leaves much to be desired, which can lead to leakage of water and gas. Also, do not exclude the presence in the product of various hazardous chemical and even radioactive compounds. The price, unfortunately, is not a guarantee of the quality of the product, therefore it is necessary to carefully examine all the goods and request photocopies of the necessary certificates.

Selection rules

In order to choose a quality bellows liner, you should consider many parameters:

- The liner should be suitable for temperature and pressure. If any type of dishwasher can be used, then for the boiler only a special hose with a mark for hot water. With what kind of water (hot or cold) the eyeliner is used, will show the color designation on the pipe or fittings: blue exclusively for cold water, red or two-color for cold and hot water.

- The bellows is chosen in such a way that its inlet nozzles are threaded directly with the connected machines and equipment, without various adapters. For this, liners are available with fittings and fittings of various sizes.

- You should buy a product with more flexibility, which can be determined in a simple way, keeping the pipe horizontal and comparing the angle of inclination.

- Fittings and cap nuts should only be made of stainless steel or brass, with sufficient thickness. Accessories from cheap aluminum indicates a fake and low quality products. The corrugation itself should also be made entirely of stainless steel.It is quite easy to distinguish it from aluminum, because by weight aluminum is very light.

- If the hose will be used to supply drinking water, you must check it for the absence of a strong chemical smell. If the smell is present, it means that the product contains materials that could harm human health.

- Other things being equal, the choice should be stopped on products of well-known European manufacturers, the sale of which provides copies of the necessary certificates. It is not necessary to acquire an eyeliner with defects visible to the naked eye: damage to fittings or nuts, deformed gaskets, poor-quality corrugation. Products made of galvanized steel will inevitably rust within 1-2 years after installation, and therefore are not recommended for purchase.

- It is best to choose the length of the hoses with a considerable margin, since the bellows are not recommended to stretch too much: this will reduce its service life. A high-quality product must be sold complete with a technical passport and warranty card for a period of at least one year.

- Though bellows liner is considered the most reliable and durable,manufacturers recommend at least once every six months to conduct an inspection for the purpose of prevention and immediately replace the items on which any defects will be found.

Bellows for water and gas are increasingly used not only in large industrial plants, but also in private houses and apartments. Despite the relatively high price, the quality of such products will allow not to worry about replacements and frequent repairs, because the bellows can last up to 35 years and more.

For more information on bellows, see the next video.