Malfunctions of Neva gas water heaters and their elimination

Not all cases justify the use of boilers for natural gas. The solution is to use special speakers. But even these relatively simple devices can break down and lose their functionality.

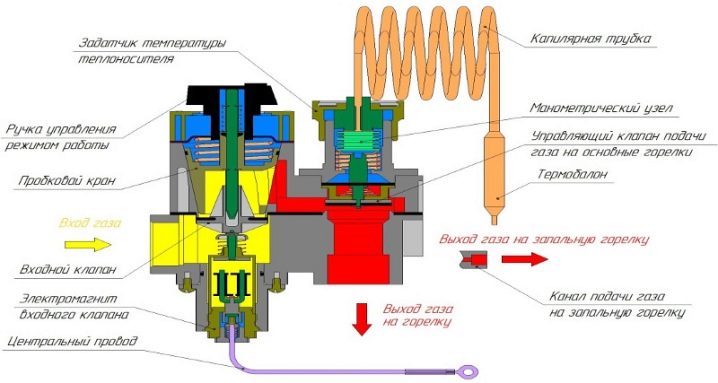

Device and principle of operation

In many cases, it is quite easy to fix the problem with automatic ignition or with other components of the apparatus, without even having to turn to the assistance of professionals. However, in order to understand the reasons why the Neva gas column does not work well, it is worth examining its structure.

The system includes:

- enclosures (for wall models - supplemented with mounting hinges);

- copper heat exchangers;

- knots of a turn of water;

- burner complexes;

- concentrators of gaseous products of combustion (diffusers);

- pipes for connection to the chimney;

- water supply tubes;

- the electrode is sunk;

- faucet regulating the passage of water;

- battery segment;

- system that regulates the power of heating and fuel consumption;

- ionization indicator of fire.

The typical method of operation of a gas burner is very simple. As soon as the hot water tap is opened, the pressure of the jet begins to act on the membrane of the regulating unit. Under its pressure, the rod moves, which opens the gas valve, and the contacts of the switching device are closed. On the electric circuit, the current from the batteries begins to flow to the controller. The electronics sends two signals at once: one valve opens one at a time, giving way to the gas, the second one produces an electric spark on special electrodes.

As soon as the fire recognizer detects a characteristic ionization, it sends a signal to the central automatic. She stops initiating a spark. Heating is carried out in a typical operating mode. The mixer valve overlaps.The membrane immediately retracts and the gas passage valve closes.

At this moment, the limit switch is started, stopping the supply of current to the controller. An electromagnet remains without power supply. Since gas does not enter the burner, it should immediately go out. The valve is connected to the same chain with a thrust meter. With the disappearance of this thrust or excessive weakening of its heated sensor opens the circuit, thereby stopping the power of the electromagnet and the passage of gas to the burner.

Malfunctions and their causes

Knowledge of the basic principles of the device geysers is very useful. But it is important to consider that the faults in each model can be different, they are determined by the features of the technical system and structural weaknesses.

Model 4510 M in reliability does not exceed most of the Russian gas systems, that is, significantly inferior to foreign counterparts. Most often, users complain that the column does not turn on well or does not light up at all. The inability to turn on the column may be due to the fact that the necessary water pressure is not provided.

Another problem is an incorrectly set handle that regulates the rate of flow of water.To eliminate such a defect is very simple. The solution is reduced only to the transfer of the lever in the left position, which sets the most intense passage of fluid. Another possible failure is that the stem of the node regulating the approach of the water remains stationary when the faucet is opened.

The reasons for this condition are:

- stretched membrane;

- break of this element;

- break of the plate containing the stem.

Occasionally it is found that the gas rod is not working. It is impossible to ignore a similar problem, because it does not allow the water rod to be moved to the right place. A sign of such a breakdown is that the column does not start when the water is turned on, it lights up only after several attempts, and it can also be difficult to turn it off.

Other problems typical for this model column:

- breaker damage;

- open circuit power supply thermal relay;

- damage to solenoid valves or relays;

- no spark generated by the electronic unit;

- discharged batteries.

Problems may also occur with models from the Lux group. Quite often, there is a situation where a spark does not run from the candle to the fuse after the water has passed through the device.As in the previous model, it can be caused with a small pressure of water. With its unsuccessful adjustment, if the column still does not catch fire and does not heat the water, it is necessary to clean the filter systems, the heat exchanger. The last measure is to eliminate the cause of the low pressure of the liquid, sometimes with reference to the structure of the water utility and other relevant organizations.

In addition to the installation of working batteries, it is important to control the polarity of their placement. It happens that the water flows, the spark jumps, but the flame still does not light up. The probable cause is the saturation of the gas line with air.

Only employees of official service organizations have the right to eliminate this problem. The owners themselves can only open the stopcock of the pipeline until the end.

In some cases, the burner burns sluggishly, the fire in it is elongated and smokes. The reason is the accumulation of dust particles on the nozzle or the internal structures of the burner. Cleaning helps to cope with this condition. When the column is turned off without permission, it can be assumed that the thrust in the system is insufficient.

In such a situation it is necessary to clean the chimney and check its tightness.

If such measures fail, it will be necessary to examine the electronic control units and the main sensors. But sometimes the burner goes out for another reason - due to an excessive rise in water temperature.

In such a situation is required:

- cut off the power of the hot water circuit;

- re-ignite the column in 60-120 seconds;

- during re-ignition, set a lower heating temperature, setting a lower gas consumption or increased water release.

When the gas heater clicks, as if a spark is formed, but there is no ignition, the defect may be due to the insulation of the plug or to the depressurization of the cable connecting the burner and the control unit. All these points cause electrical breakdown on the housing and should be eliminated immediately.

It should be noted that the design of various models of Neva speakers (such as the 5611) is generally quite similar. because violations in the work are similar. So, if in the device 6014, 4511 or 5514 the display does not show the real water temperature, one can assume either a failure in the meter of this temperature or a poor state of the screen contacts.

In the latter case, it is often necessary to change the screen unit.

Sometimes insufficient warming up of water is caused by the fact that its pressure is excessively high. When adjusting the pressure does not work, you need to clean the heat exchanger from scale, as well as get rid of the accumulation of soot and dust particles on the working parts of the burner. It is impossible to take measures in case of insufficient gas intake (also attenuating heating). If the column 4513 or 5513 starts to make an unusually noisy noise, first of all lower the pressure of the liquid by standard adjustment means. If such a measure fails, it will be necessary to change the sealing gaskets, which are placed on the connections of the water pipes.

Do not think that problems arise only when the column is ignited. Often the problem is quite unusual - the flame does not go out when switched off by regular means. The source of such a failure is usually the jamming of the rod on the gas distribution unit. Moving it by hand is almost impossible. Much more convenient and reliable complete replacement of the problem parts. Another “suspect” who also has to change is the membrane on the water node.

Important for users are also conditional error codes, issued on the built-in monitor of the column.Thus, the defect E0 indicates that gas is not being supplied (either because of the closed valve or because of the empty line). But the E1 signal indicates that for 60 seconds from the start of operation, the control electronics did not receive a notification from the fire indicator. When you first start and when you resume work after a long break, you should assume that the gas pipes are filled with air.

But before contacting a specialized service, you need to check whether the supply valve is fully open.

Sometimes the problem lies in the excessively small diameter of the hose, which brings gas to the column itself. When using bottled gas, it is worth checking whether the cylinder is empty. Additionally, you need to check if the flame indicator is too far away from the burner, if the electrode is in contact with the body. You can also assume that the candle is not in contact with the wire.

Error E3 indicates that the operation of the solenoid valves begins before the water meter measures the installed signal. Solving the problem involves replacing the valves themselves or control electronics (the second must be done only by qualified specialists).

A LO error occurs quite often, which is provoked by:

- very low water speed (less than 3.5 liters per second);

- insufficient temperature difference (initial and required by setting);

- high pressure (corrected with a special gear).

Recommendations for the implementation of repair work

Replacing the membrane with a column for each model is made only for compatible parts. Purchase goods should be strictly from official suppliers or certified dealers. As for the material, the diaphragm made of silicone is characterized by increased durability.

It is important to note that replacing a part without disassembling the entire assembly will fail. The flow of gas and water in advance is stopped, the remaining liquid is drained through the room valve.

Removing the regulators from the body by moving them towards themselves. If the speaker is equipped with a display, you need to disconnect the associated cables. The casing is removed by unscrewing the bolts or pulling it forward and upward to loosen the latches. Then you can disassemble the node itself, which is responsible for feeding the system with water. No special methods are needed to change the batteries, but you should still know how to do it.

The checkbox holding the lid must be turned 90 degrees counter clockwise. When the batteries are placed vertically and fastened to flexible latches in the shape of a letter, it is necessary to push the parts to the side and remove the batteries. Immediately after this, you can put new sources of energy and fix them in place with the same snaps. In some versions, a retractable container is used, which comes out when you press the middle part of the bottom until it clicks.

After removing the worn out batteries, they put new ones and manually return the container back, achieving the same sound.

It is easy to disassemble a gas column, most often it is necessary to do it in order to clean it. Purification should be done on both the water and gas circuits. The presence of dirt on the ignition elements threatens catastrophe, and clogging of the pipeline with scale drastically reduces energy efficiency. After extraction, the water receiving unit is washed under the maximum possible pressure. The radiator columns are also cleaned only when removed.

It should be noted that if the scale blocked the movement of the nuts, you should not demonstrate heroic perseverance or call for help from stronger people.It is more correct and safer to remove the blocking at the expense of WD-40 liquid, which allows you not to break anything. At home, a hot solution of citric acid or vinegar can be a substitute for a special liquid when flushing the heat exchanger. Replacing the cleaned part, it is necessary to replace each seal. In the gas burner itself, without the help of professionals, it is permissible to clean only the fuse (using a steel brush).

See the following video for how to troubleshoot the Neva gas water heaters.