Geyser Repair and Troubleshooting

The geyser, as well as any other household unit, is subject to certain malfunctions. Some malfunctions can be fixed in a couple of minutes, and the resolution of others can take a lot of time and effort. Today we will analyze in detail how the geyser is being repaired, and also learn how to find certain faults in such equipment.

What it is?

Before proceeding to a detailed familiarization with the gas column, you should answer the main question of what it is.

So, a gas water heater is a special device necessary for heating water in a dwelling. This process is carried out thanks to the energy that is released during the combustion of the fuel (in this case, gas).

It should be noted that both natural and liquefied gas can play the role of fuel in such units.

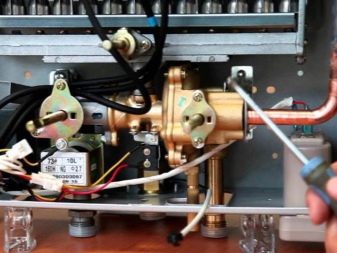

How is the unit?

Currently, a gas-powered column does not surprise anyone. Similar units have been used for a long time. In many cases, this technique becomes a real salvation for the owners of both private houses and city apartments. During the operation of such equipment, many owners are faced with various failures and faults. Most of them can be eliminated on their own, but there are also more complex cases where it is simply impossible to do without calling the master.

To know exactly how to solve this or that problem, you need to be well versed in the device column. This will directly depend on the repair work.

Central hot water supply has become so common not so long ago, if we consider this event from a historical point of view.The problem of water heating at home has always been resolved by all sorts of methods, but the most topical at that time were storage heaters for solid fuels, which are called titanium. Initially, titanium acted from coal, a little less from fuel oil or firewood. In addition, the liquid in such equipment was necessary to be heated in advance. Thus, to take a bath, people spent at least an hour. Of course, to use such a device was not as convenient as we would like. The problem of fast water heating, which was urgent at that time, was solved by developing high-quality gas-powered speakers.

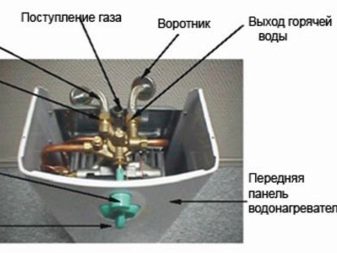

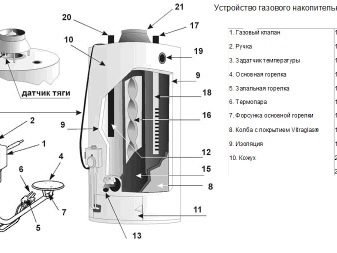

The primary work of such units is to heat the tap water due to gas coming from the city highway. In order to heat up the liquid as quickly as possible, an element such as a heat exchanger is used, in which water is distributed through a special system of thin tubes located above the burner. Thanks to this device, the liquid in the apparatus heats up very quickly - in the process of application. There is no need to pre-heat the water.

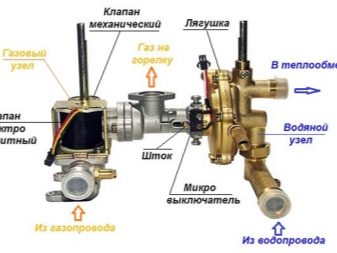

This is the basic principle of operation of a column acting on gas.All other components available in this technique are needed to ignite the fuel and adjust the water heating. In addition, it does not do in such devices and without the systems responsible for security.

Ignition in gas powered columns can be carried out. in several ways.

- From the igniter. The igniter in such units burns constantly, and is switched on using a piezoelectric element. Sometimes the igniter is started manually.

- Piezo ignition, not having a pilot.

- Electronic ignition, which is very similar to car ignition.

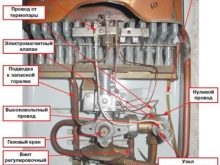

As for the necessary security systems, they are often special mechanical devices. They can be present in absolutely any column model: both new and old. The installation is equipped with a membrane technology of water intake, as well as a valve that covers the gas supply. The opening of the last part is carried out only if the liquid exerts a significant pressure on the membrane element.

Failures and their causes

Geysers are very popular units that can be found in many homes.However, this does not mean that such equipment is not subject to breakdowns and all sorts of faults. Let's get acquainted with the most common ones.

The device does not ignite

The reasons for this may be many. The first step is to make sure that such an element as a igniter is burning. If it does not work, you should call the employee of the appropriate service, who can quickly replace or clean the pilot jet.

If the ignition does not occur in the column with electronic ignition, the fuel supply is blocked by means of a valve. Learn about this process will be due to the corresponding indicator. Be sure to read the instructions, it may be possible to solve this problem by changing the batteries. Otherwise, it is worth contacting the manufacturer.

Such a column may not flare up also due to the absence of the required thrust in the ventilation well. To check the traction, it is permissible to bring a piece of paper or a lighted match to the ventilation grille. In a situation where there is no traction, you will most likely need to remove all blockages in the ventilation well. You can do it yourself,however, some owners turn to public utilities to fix this problem.

The burner may not work due to excessive wear of the water membrane part. Over the years, the membrane is subjected to deformation due to regular loads. For this reason, the device responsible for connecting the burner during fluid injection may lose sensitivity and simply stop functioning. Solve this problem is unlikely to succeed. For this reason, the membranes in the columns have to be replaced with new ones every 5–7 years.

Open the water tap for maximum power. If the heating equipment does not start up under the conditions of the most powerful head, then this should indicate that the malfunction lurks just in the membrane - it will need to be changed. In addition, it is recommended to check the filter that is placed in the water intake element of the unit. Water pressure, which is not enough to open the gas valve, may be due to contamination of the filter. The water filter does not apply to gas equipment - it is allowed to change it yourself.

In many situations, the gas column does not ignite, since bimetallic sensors do not function correctly in it.

Goes off during work

If the equipment still lights up, but in the process of operation goes out, then a bimetallic temperature sensor, which is available in the unit for its insurance against overheating, is probably to blame. Usually this fault manifests itself in different ways.

- The burner lights up, the column operates without any problems for some time, and then it just goes out and stops working. Attempts to re-ignition does not lead to the desired result. After 15–20 minutes, the equipment can be switched on again, but it will go out again after the same time. Similar problems arise because of the response characteristics of the sensor in the device.

This problem is a guarantee, but the nuance is that this problem is seasonal. Most often it is encountered in summer or winter - at a time when kitchen windows are often closed and left so for a long time. In these circumstances, the air temperature rises significantly, which is why the equipment cannot cool down to the optimum level. Such a problem can make itself felt at the moment when the warranty period is over.Unfortunately, in such circumstances, repairs will need to be carried out, spending money from your budget.

- The unit can shut down randomly, and in certain circumstances it does not burn at all. The specified "behavior" of the heating element may indicate a significant deterioration in the insulation of the sensor conductor. The closure is carried out on the body part, which provokes the operation of the protection valve. Then it makes no sense to involve employees of the gas service, since the problem here is not the gas component. However, you shouldn’t fix such problems yourself either - experts advise you to contact the manufacturer of the equipment.

Weak head

Many owners are faced with the problem of small water pressure when using a gas-powered column. If fuel is supplied, this means that the pressure in the element responsible for water intake is normal, and the reason lies in the scale in the heat exchanger. The cause of such a problem may be a pilot ignition "idle" for a long period of time.This element has time to thoroughly heat the heat exchanger, causing a strong evaporation of water residues. The scum that has appeared is not washed off due to the absence of outflow of liquid and has time to consolidate before the column is started the next time. As a result, the unit simply stops working.

Work with cotton

There are cases when the work of the gas column is accompanied by clapping. And most often, these sounds are heard not only when the unit is turned on. If the equipment slams, then it is often occurs for several reasons.

- Excessive gas pressure. In this case, the burner heats up too quickly, which causes a kind of "explosions" of the flame.

- Too little gas pressure. At the same time, air can penetrate into the inner part of the burner, which also occurs with the accompanying small “explosions”.

Low water temperature

If the water temperature remains too low, this may be due to the low power level of the equipment. It is recommended not to simultaneously open the hot water tap in both the bathroom and the kitchen. If you do not agree to put up with such inconveniences, it is better to purchase more powerful equipment.

In addition, the cause of this problem may serve as a burner blockage. This can indicate a yellowish flame.

Smell of gas when turned on

This problem is more serious and can lead to sad consequences. If you feel a persistent smell of gas, then you need to immediately turn off the column, turn off the fuel supply tap, and also take care of good ventilation in the room.

Noisy work

If the column is noisy or humming during its operation, this may indicate that the column requires repair of the heat exchanger. Such problems often arise due to the accumulation of scale.

Troubleshooting Tips

Many problems arising during the operation of the gas unit can be solved independently, without turning to gas workers. Let us examine in detail how you can fix some problems with such equipment with your own hands.

Scum on the heat exchanger

The scum accumulated on the heat exchanger can cause many problems with the unit. Most often, such deposits are collected on the inside of copper tubes, which reduces heat exchange, as well as the throughput of copper parts.Moreover, if the equipment has not been serviced for a long time, dust and soot may accumulate between the plates of the exchanger, which will also interfere with the normal heating of the liquid.

The heat exchanger is removed quite simply.

- For a start, it is important to disconnect the equipment from the main water supply system, and then drain all the liquid from the heat exchanger by unscrewing the plug under the appropriate section.

- Next, you will need to detach the pipes responsible for the water supply from the drain.

- Then loosen the screws, remove the fixing plate.

Before proceeding to any repairs, the heat exchanger must be rinsed under strong water pressure. This is to remove dust and dirt from parts. After this, it is recommended to dip these elements into the water for 30 minutes by adding detergents.

Cleaning the unit should be done with a brush (small and not very hard). Next, the item must be rinsed again under running water. The accumulated tubes are cleaned under the strong pressure of water in the opposite direction. If the scale is not removed completely, then a special acid-based product will have to be poured into the pipes. Such formulations are often prepared using citric acid. For this:

- take 100 g of citric acid;

- diluted in 1 liter of water (its temperature should be about 40 degrees).

The resulting composition is poured into the pipe heat exchanger until then, until he finds a way out of another. As a result, exiting foam is formed. After pouring the solution should be left for 15 minutes. After that, the nodes should be washed with water again.

This method of descaling is one of the most common. If suddenly the result did not suit you, then the performed operation can be repeated once more.

Radiator leak

If the unit cracked elbows or gaskets at the joints, the repair can cost the owners a tidy sum. For this reason, many users decide to independently produce such work, what is needed for:

- screwdrivers;

- set of open-ended keys;

- a vacuum cleaner;

- solvent;

- "Skin".

If you find in which part of the radiator or outlets there are holes from which liquid has flowed, you can use a soldering iron. However, this device will help only in that situation, if we are talking about a small damage. In other cases, you must act according to the scheme:

- be sure to drain all the water from the system, for which you need to open a tap with hot water, and remove the nut on the inlet pipe, which is responsible for the flow of cold water;

- now you can remove the radiator;

- inspect the pipe: if you see green spots on it, you will need to clean them and see if there are any damages on these places.

When you found the places that caused the leaks, need to eliminate them immediately.

- Sand the found holes and immediately wipe with a cloth moistened with solvent. This will remove all grease, carbon and dirt.

- Next you need to take the rosin with solder, and then to tin with their use the damaged area, using a 100-watt soldering iron. Instead of rosin, you can take aspirin.

- Now you need to wipe the hole / crack with solder. When it cools, you can add a tin of 1–2 mm.

Tips and tricks

For repair of the geyser should contact only those organizations that have in their arsenal all the required certificates that allow them to work with such equipment.

If there is gas equipment from such companies as “Ariston” or “Junkers” in your house, then it is not recommended to make repairs with your own hands - betterentrust the work to professionals.

Experts do not advise buying batteries in stalls and kiosks on the street. Especially this advice applies to the cold season, because batteries reduce their charge under the influence of low temperatures.

Do not attempt to correct the serious problems of the speakers yourself, especially if we are talking about the persistent smell of gas during their work.

If a gas column drips in a certain place, then you can repair it yourself. However, it should be borne in mind that when the holes, the size of which is about 5 cm, many masters install a temporary pad of copper or aluminum plate. Fix this element with a dense wire or metal tape. But do not think that such refinement will last for a long time, so it is better to turn to the replacement of the radiator.

Whatever repairs you carry out, it is always necessary to shut off the gas and water supply to the column.

Any components for gas equipment should be purchased in specialized stores.

After dismantling the heat exchanger and assemblies, it is necessary to carefully and carefully examine the tightness of all existing connections in the process of re-installing the parts.

If you have little idea how the gas column is arranged, then it should not be repaired: you can harm the device and not repair it.

If you decide to install a gas boiler in your home, then you should not forget that this equipment should be supplemented with a chimney. It is useful for removing waste gas combustion. Such details consist of both horizontal and vertical segments, along which the chimney should go under a slight slope.

Consider that the more powerful the gas column is, the more impressive the volume of liquid it can heat up during a certain time period.

To install such equipment should be only in the kitchen - in the bathroom it can not be done. An exception can be only those cases where the last room meets all the requirements (this happens very rarely).

Experts recommend that modern consumers buy high-tech models of gas water heaters, in which there is a special switch "winter - summer." These modes will need to configure only once. After that, you will be able to easily switch them in one motion.

Geysers are recommended to be equipped with such detail as a cleaning filter. It will make the water much softer, eliminating excess impurities.

Periodically clean the internal parts of the column from dirt and grime so that they do not cause serious damage.

If you purchased a high power unit, it is recommended to connect it to the mains using a voltage regulator.

The main malfunctions of the gas column, see the following video.