Water heating cable: technical characteristics and installation features

When designing communications for a private house, many think about how things will be with the water supply during the winter period. There are many solutions to this problem, of which priority is the use of a heating cable for the pipeline.

Design and purpose

Laying water in private homes or cottages is not an easy task. However, the greatest difficulties with water supply occur in winter, as communications often freeze and deform.To solve this problem, you can lay them below the level of soil freezing. To do this, you need to know to what level it freezes through in your area in order to dig a trench of the desired depth. In most cases, it is 1.5-1.7 meters.

Hidden underground systems will not freeze due to the positive temperature of the surrounding soil.

Wetlands or areas close to water bodies have groundwater adjacent to the earth's surface. Therefore, during floods or melting snow, communication wiring will be under water and may collapse. However, when laying pipes to a depth of 50 centimeters, connecting an electrical cable and carrying out proper thermal insulation will eliminate the need for a deep trench.

Special attention should be paid to the zones most exposed to temperature effects - this is the area where the pipeline enters the room. In this case, the ideal option would be to install a heating cable for the water supply. Laying such a scheme is preferable for warming the frozen sections of communications. It will prolong the life of the structure for a long time, despite the harsh climatic conditions.But even in the southern regions with short-term freezing temperatures, a set of measures to preserve pipes from freezing is still worth implementing. It is able to preserve the integrity of the HDPE pipes, metal-plastic, metal.

The principle of operation of the installation is based on the generation of heat through the current flowing along the line, which prevents the pipes from freezing in winter. When choosing a heating cable, pay attention to the thermal conductivity (W / m), indicating the power level.

This unit has many advantages:

- will protect the water supply system from freezing even at very low temperatures;

- the cable can be mounted on the surface or inside the pipes;

- The device is protected from burnout, so it is possible to install it on drinking water supply systems (there are varieties of special heating installations made from environmentally friendly raw materials);

- simple installation process and convenient operation;

- adjustable power during temperature changes.

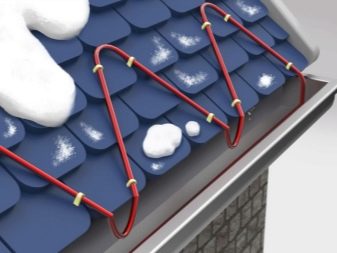

The heating device is used for heating gutters, sewage and water pipes, tanks, gutters.

The cable heating device is also used for solving such tasks as:

- installation of the "warm floor";

- laying along the entire length of the roof to prevent icicles from forming;

- heating the soil in greenhouses and greenhouses;

- heated staircases, ramps, outdoor areas and sidewalks;

- construction of anti-icing schemes on ships, in aviation, on railway transport.

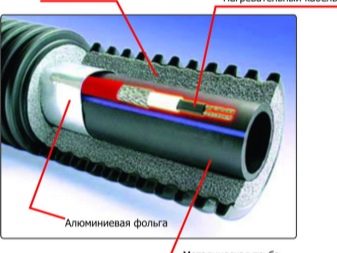

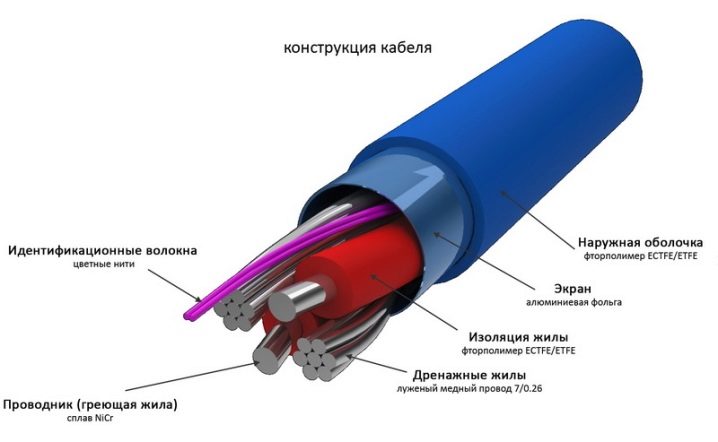

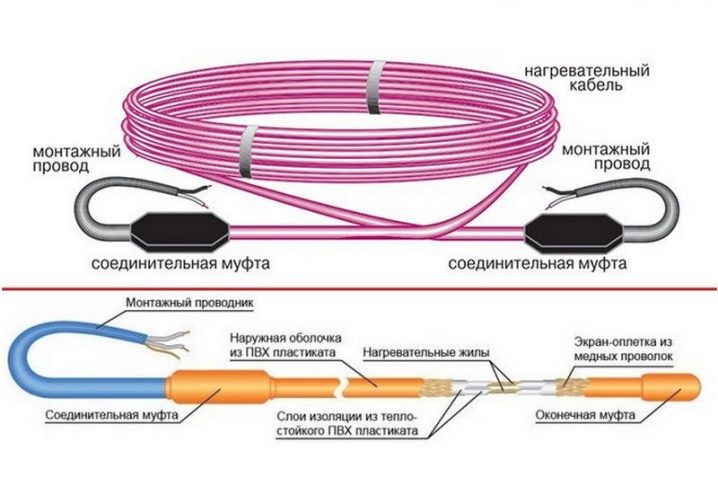

The heating element consists of:

- heating metal conductor;

- heat-resistant PVC insulation, which is covered with each core;

- an insulating layer of fluoroplastic in which each conductor is placed;

- subsequent copper screen in the form of a grid;

- hermetic end coupling;

- the gland.

The heating component, which is placed in pipes with water, is covered with an outer shell that protects from moisture, temperature changes, aggressive substances. It also has a thermostat that monitors the temperature level of the liquid. It turns off the heating function after heating to a certain level. This element eliminates possible overheating and saves electricity during the heating process.

Species

There are two types of cable for heating: resistive and self-regulating. In the first model, the metal is used to heat after passing electricity. Here there is a gradual heating of the metallic conductor. A characteristic feature of a resistive cable is the constant amount of the same amount of heat. At the same time, the temperature indicator of the environment is not important. Heating will be carried out at full capacity, the amount of electricity consumed will be identical.

To reduce costs in warm seasons, temperature sensors and temperature controllers are installed (similar to those used in the "warm floor" system). Parts of this design should not be brought close to each other and crossed, otherwise they will overheat and fail.

As a plus, you can note:

- high heat transfer and the power level of the circuit, which is considered the main parameter for products with large diameters, the need to heat numerous composite components (fittings, adapters, taps);

- ease of use, low cost.

The disadvantages of the system are:

- Additional financial costs for the purchase and installation of thermal sensors, automation and units for control.

- The ready set of resistive cable is realized to the established length, moreover, it is impossible to independently change the footage. The contact sleeve is performed strictly in the factory.

It should be noted that the plumbing resistive heating system is divided into single-core and two-core. In general, two-core models are used, although their value is higher than single-core ones.

Instances differ in the connection process. So, single-core connect to the outlet with both ends. Two-cores are equipped with a plug at one end, at the other end they are fixed with a usual electrical cord with a plug for connection to the 220 V network. Keep in mind that the resistive conductor will cease to function after the cut. When buying a bay larger than necessary, you need to lay it completely.

Self-regulating wire is a metal-polymer matrix. Here, electricity is carried out using cables, and the polymer between the two conductors is heated. The material has an interesting property: with increasing temperature decreasesthe amount of heat generated, and vice versa. These processes take place regardless of the nearby nodes of the wiring. Thus, he independently controls the level of heat, for which he received his name.

This species has solid advantages:

- the possibility of crossing and incombustible;

- the possibility of cutting (there is a marking denoting cut lines), but then a terminal sleeve is necessary.

The only drawback is the high price, but the period of operation (in compliance with the rules of operation) is about 10 years.

When choosing this kind of heat cable, pay special attention to:

- Internal insulation. Its resistance must be at least 1 ohm. The design must be solid and have appropriate thermal conductivity.

- Shielding film in the wire. Thanks to her, the cord becomes stronger and gets zero mass. In more budget options, the presence of such a "screen" is not provided.

- Type of protective layer. When carrying out installation activities in anti-icing structures, the heating device should be covered with a protective sheath made of thermoplastic or polyolefin, which is resistant to UV rays.For installation in plumbing communication, experts recommend giving preference to a thermal device covered with external insulating fluoroplastic lamination.

- The use of wires in a hostile environment will require the presence of a fluoropolymer layer.

- The level of heating conductors. The heating temperature is 65-190 ° C. The conductors of low temperature parameters are intended to heat the pipe with a small diameter. The medium temperature option is suitable for networks with a large diameter roof. The high-temperature sample is used for industrial purposes.

When choosing an automatic cable, check with the seller for information on passing aging test products, as this is an indicator of product durability.

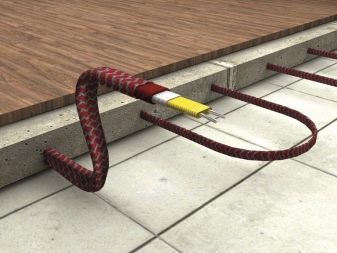

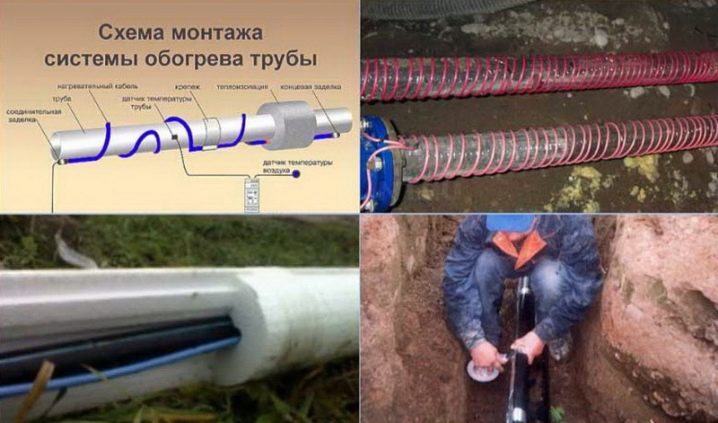

Ways to post

Installation of the heating system is possible inside the pipelines or outside. The process of laying in pipes is simple during installation and maintenance. In the case of the placement of the heating wire on the surface of the pipe product buried in the soil, the repair work will be complicated. In most cases, the wire is attached by a single line through the pipe.It is considered undesirable to place it on top of the reinforcement, since in this case there is a high probability of mechanical deformation due to objects or stones falling from above. Also, the freezing of water begins from the bottom, so such an arrangement of the heating element is considered more efficient.

Options for placing the heating wire on the surface of the pipe:

- location in one or several straight rows, which are located at a distance from each other;

- spiral laying around the pipe with a given pitch.

Cable filaments are fixed with the help of specialized aluminum tape. Heat transfer is enhanced if the pipe is wrapped in foil before installing the heating product. At the turn of the electrical wire must be installed as close as possible to the outer radius. The sections that have metal components of the support are amplified by heating when additional loops are inserted into the entanglement. A circuit with a thermal sensor should not be placed near the heating point. It should not be placed on the surface of the reinforcement, but in the side region. The point of attachment of the sensor is glued with aluminum tape, from above it is fixed by it.

Laying inside the cable will require the purchase of exactly the model that is designed for such problems with a circular cross section and strong insulation. In the set there are elements for laying it inside the pipe: washers, bushings, seals.

The sequence of installation inside the tubular:

- each component for entry into the system is put on the wire, then it connects to the cold cable;

- the entry point is equipped with a tee having a special sealing sleeve;

- the wire is inserted into the pipe to the desired length, however, you need to remember that you do not need to pass it through the valve, tap and places with sharp projections that can deform its integrity;

- fixing all fasteners, gland component to protect against depressurization.

Installation of heating system

Despite the large variety of heating connections, during connection to the cable system there is a need to combine the blocks and mount the tees at the end points.

To connect the heating system, stock up with the necessary tools:

- screwdriver;

- office knife;

- pliers;

- side cutters;

- industrial hairdryer.

The process of preparation and insulation end of the coupling:

- pull back 20 millimeters from the end of the wire and cut off part of the outer sheath with a knife;

- remove the metal sheath with a screwdriver and pliers;

- in the case of a self-regulating cable, cut with a side cutter 10 millimeters from one of the energy-conducting veins with the matrix that is on it - you will have 2 wires of different lengths;

- insert the wire into the heat shrinkable sleeve and begin the process of heating it with an industrial dryer at a temperature of 350 degrees;

- clamp the edge of the heated coupling with pliers.

Implementation of measures for combining 2 pieces of wire:

- back away from the edge of the line 20 millimeters, cut off part of the outer layer;

- peel the metal braid with a screwdriver and twist all the thin wires into a cord;

- bend it to the opposite end of the cable and press it against the outer shell;

- remove intermediate insulation;

- clean the wires and move them apart;

- the matrix is cut in a triangular shape, if you have a self-regulating cable;

- similarly prepare the other end of the segment and put a shrink tube with a large section on one of the cables;

- insert the wires of the two pieces into the narrow tubes (each core should have its own tube) and proceed with the heating;

- close the insulation section using a large tube and heat it with a hairdryer. The installation process is complete.

In order for the circuit to operate in an economical and safe mode, it is recommended to install two devices: RCD and thermostat. The first construction will prevent the leakage of energy, the second one will calculate the temperature by means of a thermal sensor. This will allow you to always control the consumption of electricity and, accordingly, to calculate the costs of utilities.

Independent manufacture of cable

Thermocable can be purchased in specialized stores, but will have to pay for it a round sum. But if you have certain knowledge, you can assemble the installation yourself. Power telephone wire (field) can be replaced with a proprietary heating due to the similarity of characteristics and forms. This cord has durability, rigidity. Reliable insulation allows it to be used in a wet environment.

But keep in mind that a heating unit based on a telephone cable will not have some functions: self-regulating mode, special insulation.However, these characteristics are not essential, so you can safely install a heating unit assembled by yourself. Installation work will not cause much trouble. First of all, determine the venue of the system. When positioning the wire on the outer layer of the tubular, attach the cord tightly to the fixture. Wrap the received device with tape, wrap aluminum tape over it, which will additionally fasten the heating part.

A similar scheme can be adapted also for sewer communications. It is only necessary to take care of the protection of the device from the liquid by means of hydro and thermal insulation.

Arrangement of thermal insulation

To prevent internal communications from freezing at low temperatures, it is possible to do with special heat insulating means. Today they are offered in a large assortment.

The most popular heating materials that are suitable for pipeline structures are:

- Fiberglass insulation. In most cases, this raw material is used to prevent metal-plastic products from freezing.Glass wool requires a sufficient level of insulation due to the rapid destruction caused by low density. It is recommended to use roofing material and fiberglass.

- Option from balzat is realized in the form of a cylinder. Laying does not require specialized trays, the base itself is made of basalt raw materials. Parchment, foil and roofing material are suitable as a protective surface.

- Foamed synthetic rubber stands out among other thermal insulation samples of elasticity and flexibility. This component on sale can be found in the form of tubes of different diameters and in sheets. Its main purpose is to protect water supply networks, heating and sewage communications from the cold.

- Foam for cable insulation is available in the form of a shell. It does not require an external coating, it is installed as desired. Foam materials will be able to heat underground and surface highways.

- Polystyrene thermal insulation design looks like segments and half-cylinders. It is not afraid of contact with water, so it can preserve the integrity of underground and surface pipelines.

- In the case of a pipeline structure located in an excavated ditch, a foam base can be used. If you decide to limit yourself to simply plunging a tubular into the ground, you will need a solid, warm base. Alternatively, you can try to pull a rigid tube (plastic sewage) onto the surface of a crushable base (for example, expanded polyethylene, having closed cells).

Tips and tricks

Useful tips:

- In the process of mounting on a surface that has an unstable thermal mode (when one part of the product goes outside, the other remains inside the building and ends with an exit to the outside), choose an automatic warming cable. This choice stems from the fact that the use of high-quality and durable resistive installation implies the installation of temperature sensors at several points along the entire length. This will help prevent overheating and premature device failure.

- Properly check the thermal insulation, which will be laid on the pipe and wire. Only high quality heat insulating base can reduce electricity consumption and increase line capacity.

- When laying, carried out by winding on the pipe surface, be sure to familiarize yourself with the permissible bending limits before purchasing the cable. If the bend exceeds the allowable limit, the wire will be broken.

- The use of a heating installation to warm up the household pipe will be possible if the connection is made using an electric leakage relay. This is to prevent electrical damage if the insulation is damaged.

- For installation of heating equipment in hazardous areas, specialized samples must be used, which are equipped with certain components of the chemical and coal industries. In this case, install cable products that are allowed for use in these areas. Otherwise, an explosion or a strong fire may occur.

To learn how to install a heating cable for water supply, see the following video.