Cast iron stoves for a bath: the pros and cons

A quality oven is an essential component for a comfortable stay in the bath. The greatest pleasure from staying in the steam room is achieved by the optimum air temperature and the softness of the steam. A simple firebox for firewood has long been replaced by a wide range of models and the choice of manufacturers.

The popularity of cast iron stoves is constantly growing. But before deciding to install such a structure, it is important to study the features characteristic of this material, its advantages and disadvantages.

Special features

Sauna ceremony is a traditional ritual, used not only for recreation, but also for health purposes. Cast iron is becoming increasingly popular as a stove material.

The pig-iron furnace for a bath differs from its predecessors by a number of advantages.

- High heat resistance, which is achieved by adding chromium. An additional advantage is the ability to withstand sudden changes in temperature.

- High level of heat capacity and low level of thermal conductivity. It is on the basis of these properties that the room will quickly warm up, but the accumulated heat will go slowly (up to 9 hours).

- Heating equipment made of cast iron has thick walls that easily transmit heat, but do not burn out from high temperatures.

- Subject to compliance with the installation technology, the cast-iron stove is absolutely fireproof.

- The small size allows you to place the equipment in the room of any parameters.

- To install such a furnace does not need a foundation.

- For the smooth operation of heating equipment requires a small amount of wood.

- Ecological purity and safety of the material itself.

- During operation there is no oxygen burnout.

- Allocated steam is not only not harmful to humans, but also brings certain health benefits.

- Long service life in case of proper operation of the device.

The heating device from cast iron is characterized by universality: it simultaneously heats the air in the steam room and water. The furnace made of cast iron fits well into the interior of the bath and harmoniously looks in the steam room with any design. Despite the fact that the stove has a compact size, it weighs quite a lot - about 60 kilograms.

At the same time, it is easily transported and installed.

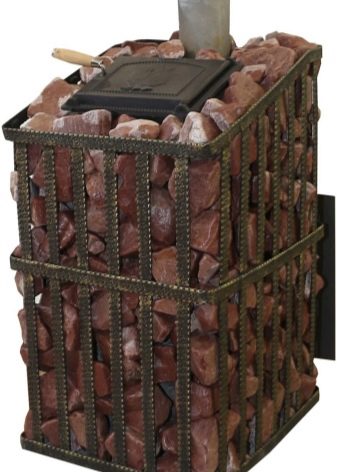

Furnace linings are selected solely from individual wishes and can be made from virtually any material. For example, it can be overlaid with bricks or tiles, or it can be not subjected to additional external cladding. Cladding may be required if an unscrupulous manufacturer has saved on the quality of the material produced. Poor cast iron can crack during operation. To avoid such troubles, it is recommended to veneer the heater.

For installation in the bathhouse of a private house, you should choose the highest quality cast iron stoves. It is not worth saving when buying a product, it is important to carefully study its chemical composition, so that when using it you will not be faced with material deformation.

There are several main disadvantages of cast iron stoves.

- At the stage of installation it is necessary to provide for the construction of a full-fledged chimney, which is not a prerequisite for the installation of electric boilers.

- During operation, the elements of the furnace should be treated with heightened accuracy, since the material is brittle.

- High cost in comparison with the analogs made of steel.

- It is impossible to sharply cool the furnace, as the metal may crack.

The operating principles of all models are almost the same, there are only slight differences in the level of heat preservation and heat transfer index. Different types of furnaces, these indicators vary depending on the characteristics.

Kinds

The main models of cast iron stoves from Russian manufacturers that appear on the modern market meet all modern requirements and have excellent technical characteristics.

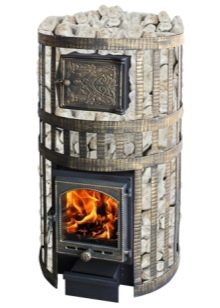

Wood cast iron stoves for baths are in high demand because of the simple design, high level of reliability and ease of operation. The shape of the furnace can be rectangular, square or round.

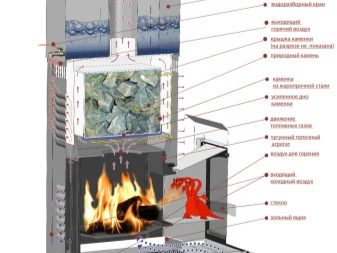

The principle of operation of such a furnace is quite simple:

- The wood burning stove is equipped with a firebox into which solid fuel is put;

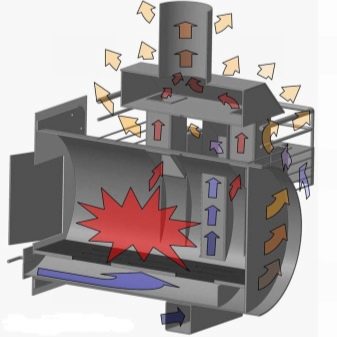

- In the process of combustion, heat is generated, which is received either by the furnace body or the heater.

There are models where the construction provides for the presence of a hole that allows the laying of firewood not only through the double room, but also in the next room. Models that can be categorized as “advanced” are equipped with a water tank in which water is heated and used for washing. Heating occurs due to heat, which gives the body.

Combustion products are removed through the ash pan located under the furnace.

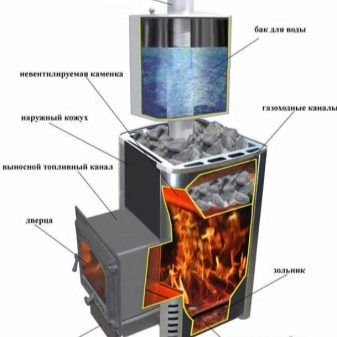

The next type is a stove with a closed heater. In terms of fuel consumed, this is the most economical option. The level of soot formation in them is significantly lower than that of other models. The volume of heated space - up to 45 m3. One of the design features is the location of the stones inside the furnace itself. They are completely hidden from the eyes, the water supply is carried out through the hole located on top, as a result, the liquid turns into dry clean steam.

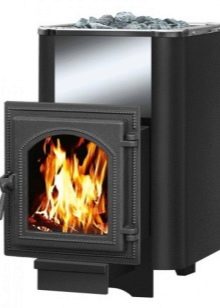

Another popular type of heating apparatus for a bath is a stationary stove with an unbearable firebox. The size of such furnaces is small, and they perfectly complement the interior of the steam room. They are often used in limited-sized buildings without utility room. Sitting in the steam room, you can watch the wood burning. Of course, the permanent storage of firewood near the stove is prohibited, as this is fraught with the possibility of a fire.

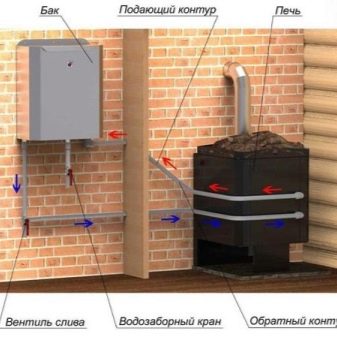

The next model is a stationary stove with a portable firebox. In such models, the firebox is taken out in the back room or in the rest room.

Firewood can be safely placed next to such a stove, since the probability of fire is excluded.

There is not always the possibility or desire to heat the stove with firewood. Therefore, an excellent option would be the acquisition of gas cast iron stoves. In addition, a wood-burning cast-iron stove with the help of specialists can be converted into a gas appliance.

This procedure cannot be carried out on its own, as it requires the installation of a certified gas burner. She is examined by a gas service inspector. If an iron wood-burning stove could trigger a fire, then the gas creates a risk of explosion.

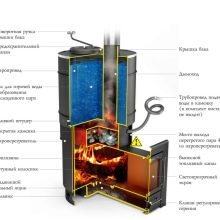

The next category of heaters is a cast iron stove with a heat exchanger. A heat exchanger is a pipe system through which water flows continuously. The exchanger heats the water by direct contact with the heat source. It can be located both outside and inside the furnace casing, in other cases it is a coil that winds around the chimney.

Currently, there are several proven manufacturers that manufacture all of the above types of furnaces.

Manufacturers

Owner reviews are a great opportunity to explore the features of a particular model before buying a stove. On their basis, a list of manufacturers worthy of attention.

For the range of ovens "Kalita" is:

- Jack Magnum;

- Joy;

- Arched;

- Taiga;

- Huntsman;

- Prince Kalita;

- Gaudi;

- Kalita Extreme;

- Vityaz.

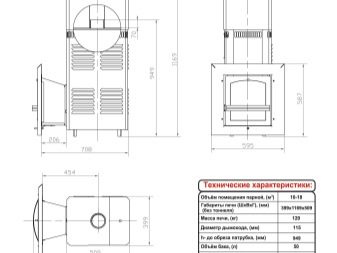

Manufacturer - Izhkomtsentr VVD. Collapsible type of construction, the body of the furnace is made of cast iron with a thickness of 1 cm.Some of the models are characterized by a closed type of stove, controlled ventilation, and the presence of a flue tunnel made of materials such as stainless steel and cast iron.

You can decorate the firebox door in two different ways: with the help of a coil or a soap dispenser. These stones have a positive effect on the body, increase the overall level of immunity and normalize blood pressure. There are models with built-in heater in the furnace. But closed Kamenka is recognized by experts as a preferred option for use. This is due to the fact that in an enclosed space, the stones are heated evenly from all sides, due to which steam becomes easier and more useful.

Arched model features a beautiful design and stone veneer. Kamenka in the form of an arch has sashes decorated with forged linings. The temperature in all parts of the steam room is stable and is distributed evenly due to the increased thermal inertia. Kamenka holds up to 120 kilograms of stones, heating takes less than 2 hours, after which the temperature is maintained at the right level for a long time.

Model Jack Magnum is made with an open stove. The amount of stones that are placed inside reaches 80 kg. Thanks to the thin lining, thermal energy quickly accumulates and then spreads through the steam room.

Along with numerous advantages, the model has some drawbacks:

- Components (grate) quickly fail, it is problematic to replace them;

- The furnace is heated for a long time in the cold season;

- The firebox has a low height;

- In the place where the fuel channel connects with the body of the stove, there is a narrowing, which is very impractical.

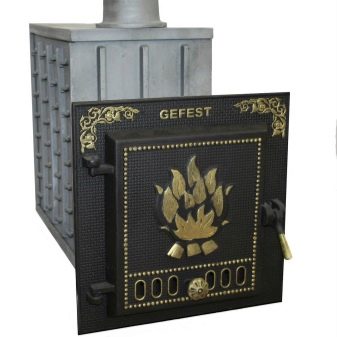

The next market segment is the Hephaestus range of stoves. Furnaces of this brand surpass the equipment of competitors in many respects due to an important advantage - accelerated heating of air. It takes only 60 minutes for the surface temperature to reach 7000 degrees. Flame arresters are built into the Hephaestus oven equipment, so fuel is consumed very economically.

Another advantage of these furnaces can be called their compact dimensions and weight. In addition, the equipment can withstand 15 - 20 years of continuous operation without loss of useful properties.The manufacturer can choose a stove for placing any area.

And to install the equipment, do not need an additional foundation.

The furnace is made of cast iron, the thickness of which varies from 10 to 60 mm.

The model range is as follows:

- PB 01 The main plus is the presence of steam insulation (in order to avoid injury to people), lining with a natural material talcochlorite. This model has three variations, each of which holds about 300 kg of stones.

- PB 02 Supports 2 modes: dry air and wet steam. On the firebox door installed heat-resistant glass.

- PB 03 Compact oven convection type. With it, you can heat about 25 square meters. This model has its own modifications: PB 03 M, PB C, PB 03 MS. All of them are designed for fast heating of small rooms.

- PB 04 These are wood units of the closed type. The dimensions of the furnace are compact, the equipment is equipped with a waste tank and a chimney. The furnace itself is made of cast iron, its doors are made of durable glass.

The official manufacturer emphasizes that the quality of the casting at each stage is under the continuous control of specialists, and just one bookmark of firewood lasts for 8 hours of continuous operation of the unit.The manufacture of furnace equipment is possible in the version of "economy" or in an elite lining of several different types: "Russian steam", "Optima" and "President".

The next type is the Vesuvius cast iron stoves. The model range of Vesuvius consists of such furnaces as "Hurricane", "Sensation" and "Legend".

The “sensation” is heated directly from the steam room. It has a ventilated stove and a fully sealed firebox. The stones heat up to 350 degrees.

A very decent copy - "Vesuvius Legend" weighing 160 kg. It is intended for use in steam rooms, whose area reaches 10 - 28 cubic meters.

“Hurricane” is an ideal stove for those who appreciate the traditions of the original Russian bath. Kamenka is closed, located in the upper part. The output steam is fine, dispersive. The equipment weighs about 110 kg, the stove can be heated from the adjacent room with a steam room. Directly the furnace casing is painted with heat-resistant black paint. Heating stones reaches a temperature of +400 degrees.

According to experts, it is impossible to warm the stones in the grid to the desired temperature, the steam becomes heavy and does not carry any good.

The furnace "Fountain of 20" is suitable for both wet and dry bath. The furnace is made of real cast iron, not subject to fading. Solid furnace, stove covered with heat-resistant enamel.

The Termofor furnace possesses high efficiency and democratic cost. The manufacturer gives a three-year warranty on the integrity of the metal.

Main characteristics:

- High security. Each furnace passes all necessary tests and is made according to the existing standards.

- Increased strength. To create using heat-resistant steel with a high percentage of chromium.

- Two modes of operation: fast warm / maintain temperature.

- Soot self-cleaning system.

- Great design.

- Ease of transportation.

Popular oven "Sudarushka", the distinctive features of the model - fast warm-up and excellent heat capacity.

The list of positive aspects of this equipment can include:

- economical use of the fuel material;

- universality of design;

- simplified installation procedure;

- small weight;

- ease of care;

The design also has disadvantages:

- Often there are complaints that the furnace firebox quickly burst. The reason for this may be the poor quality of cast iron or incorrect operation.

- Quickly boil the liquid in the tank.

The above designs are in high demand because of their relatively low cost and ease of installation.

Be sure to mention the Finnish stove for a bath. Their range is wide, but the cost is significantly higher than on the model of production of the Russian Federation. It is justified, since the manufacture uses more expensive metal.

The main producers of furnaces are:

- Harvia is the leader in terms of service life;

- Narvi company - manufacturer of high-ecological products;

- Helo is a democratic brand with a simplified design.

Despite the high cost, Finnish-made kilns are recognized leaders in the global market.

Tips for choosing

The market offers a wide range of different models of furnaces. Which of them is better, the buyer decides, focusing on their individual needs and financial capabilities. In order not to be trapped, you should get acquainted with the advice of experts.

These recommendations can help with the selection and suggest what exactly you should pay attention to when choosing.

- The quality of the material. It is very important to understand that the metal is different in thickness and other quality characteristics.

- Placement of the furnace. The furnace is normal and elongated. Extended mounted in the wall opening, which allows the stove to be heated both from the rest room and from the steam room.

- The type of water tank can be built-in and mounted. When choosing, it is worth considering the specificity of the bath.

- Performance level Typically, the manufacturer places detailed information about how much room a particular type of furnace is able to heat.

- Type of fuel. Based on what kind of fuel will be used for heating, you should pay attention to the wall thickness of the selected model.

- Type of door. Tempered glass models are much more expensive than analogs, but a wonderful view of the fire will be provided for a long time.

- Whether completely the furnace is made of cast iron. There are manufacturers who, wanting to reduce the cost of their products, replace some elements with steel ones. The disadvantage of such products is that steel significantly reduces the life of the device.

For those who love and know how to work with their hands, there is another option that does not involve the acquisition of design.

The furnace can be made independently from an old cast-iron bath, which is not used for its intended purpose.

But whoever they were made, cast iron stoves are excellent products with high performance characteristics that can be used both in the sauna and in the Russian bath. When buying, it is important to carefully carry out a visual inspection and examine all the parameters of the device to avoid the wrong decision and purchase the most suitable option.

On how to choose a cast iron stove for a bath, see the following video.