Rockwool Venti Butts: Features of Mineral Wool Plates

Rigid mineral wool slabs consisting of hydrophobic stonewool Rockwool "Venti Butts" "D" and "H" are used as the main insulation when installing ventilated ventilated facades. Our article is devoted to the features of this material.

Properties

The plate “Venti Butts” is a product of the Danish company Rockwool, which has been carrying out mass production of heat-insulating building materials since 1937. The high demand for the products of this company in Europe and in Russia is due to the possibility of its use in the installation of the latest thermal insulation systems. This company is engaged in the production of acoustic insulation "Acoustic Butts" and mineral wool insulation, among which the high-strength Rockwool "Venti Butts" plates constitute a separate subgroup.

These heat-insulating materials are characterized by a long service life, as they do not shrink over time.

These products are distinguished from their counterparts from other manufacturers by their compacted face layer, which does not let in cold air. The small weight of products of this brand considerably reduces labor costs during their installation and transportation.

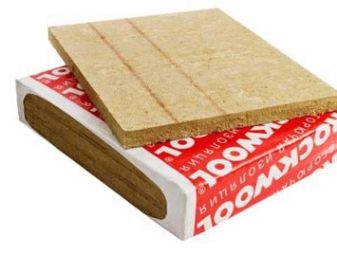

The basis of Rockwool products is made up of fibers obtained by melting basalt. The binding components are phenol-formaldehyde resins and impurities with water-repellent properties, which serve to give the slab the necessary strength and rigidity. The specific proportion of such components is about 2%. After melting, they become completely inert to the environment, which makes the Rockwool mineral wool environmentally friendly.

At the same time, due to these additives, a low percentage of moisture absorption by this plate and resistance to various external influences is achieved. This makes the brand's products an optimal type of outdoor insulation, and because of its waterproofing characteristics, it can be used in the so-called floating floors as a basis.

Minvat “Venti Butts” is produced in the form of hard fragments, having 1000 or 1200 mm in length and 600 or 1000 mm in width with the thickness of the product 30-150, 200 mm. The most common and in demand are the dimensions of the slab 1000x600x50 mm and 1000x600x100 mm. The protective package containing from 1 to 8 sheets of material is made of PVC film. According to reviews, a material thickness of the order of 50 mm is quite enough to organize high-quality thermal insulation. The load on the foundation of the structure is minimal.

Rockwool Venti Butts slabs weigh about 2 kg each.

Specifications

Rockwool Venti Butts 1000x600x50 mm and other sizes demonstrate thermal conductivity of 0.035-0.041 W / m x K. This indicator depends on the air temperature. Density is 90–100 kg per cubic meter, and for lightweight “N” slabs - 37 kg / m3. The degree of vapor permeability of products is 0.30 mg / mh hh Pa, and the percentage of their water absorption is 1.5.

The high water resistance of mineral wool and its ability to withstand weathering is explained by its acidity modulus equal to 2. The plate's pull-out force is 3–4 kPa, and its tensile strength at ten percent deformation has a value of 10 kPa. Rockwool plates belong to the NG class of fire safety.

Installation instructions

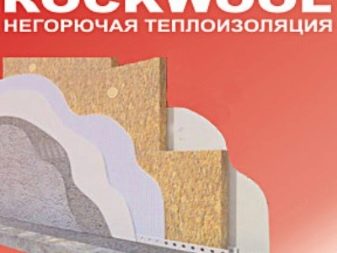

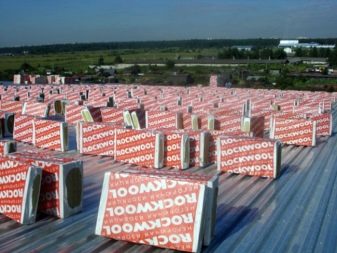

As already mentioned, slabs of the brand "Venti Batts" 1000x600x50 mm and other sizes are heat insulating elements of ventilated facades.

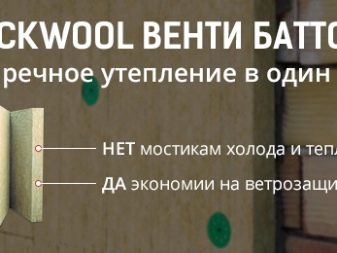

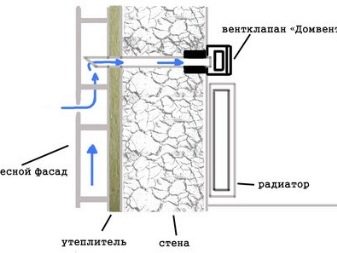

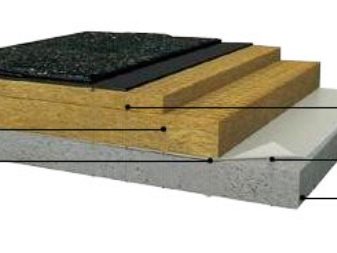

A distinctive feature of such facades is the fact that the cladding part in them is not applied to the layer of mineral wool, which has a base of pre-reinforced plaster, but is fixed by means of special fastening elements that are drilled into the wall. As a result, a small blown gap is formed between the cotton and the cladding layer.

Cheaper mineral wool insulators in such a situation are covered with a layer of wind-proof film, but such insulation is not required for the insulation of the Venti Butts.

The work consists in preparing the base and all the necessary materials, marking the place for fastening the facade, if it is assembled on a special frame and mounting all fasteners. Then the plates are fixed to the wall with mortar. The installation continues until the entire wall is covered with plates. After the mortar has set, the insulation is additionally fixed with plate-shaped dowels and, if necessary, equippedwaterproofing.

Then the frame of the second level of the facade is assembled, and the facing elements are mounted. If we are talking about creating a single-layer standard facade, the process is much simpler: the plates in this case are simply plastered, and the lining is applied over the plaster.

The frame assembly can be combined with the ventilation of the facade. This is done if ventilation is considered as an additional useful factor. In this case, the installation is carried out on the frame of a metal profile, the elements of which are attached to the plate. The construction of the frame protrudes 3-5 cm above the level of the plates, due to which a gap is formed allowing the facade to be ventilated naturally, although this is not as effective as compared to standard technology.

Range

The products of this brand are represented by four varieties that have minor differences between them.

- The first type includes rigid elements "Venti Butts", being insulation for hinged facade systems and belonging to the standard version, durable and resistant to external influences.

- The second type of this product is double-layer slabshaving a combined structure. Their upper layer has an increased rigidity and density, and the lower one is lighter. For this mineral wool, the designation “D” is accepted, and its cost is slightly higher than that of other brands. For ease of installation, a marking is applied to the upper outer layer, although it is easily detected by touch.

- Insulation Rockwool "Venti Butts Optima" refers to the third type of product. By its properties, it is very close to Venti Butts, but is a more versatile option. Its operation is allowed together with the light-transmitting outer lining. This type of insulation is recommended by experts for arranging fire boxes near window openings.

- Rockwool Light Plates with H Marking are the fourth variety of this type of products. They are used to create the inner layer in the systems of suspended facades with thermal insulation of two-layer type. Their difference is low density and low weight, which is almost 3 times lower than that of similar products of other types, which serves as an additional factor in reducing the load on the foundation.

The minimum thickness of the elements “Venti Batts N” is 50 mm, and the thermal conductivity coefficient is 0.036 W / mx K, which is an indicator of the high level of their thermal insulation.

This mineral wool belongs to the KMO flammability group; therefore, it should not be used for mounting open structures.

Benefits

Consumer reviews indicate that these products are practically free from flaws. A certain minus could be called their very significant cost, but this disadvantage is justified by the high quality of such mini wool, ideal for the installation of suspended ventilated facades.

Consider the merits of products.

- Eco-friendly basalt fibers, as well as their synthetic filler, do not adversely affect human health. In comparison with glass wool, stone fibers are much less fragile, therefore they do not form dust and do not lead to skin irritation.

- Insulated with such stoves walls, due to their vapor permeability, can "breathe", which is especially valuable when finishing wooden houses. And because of their high security, the elements of Rockwool "Venti Butts" for a long time withstand directexposure to flame, preventing its spread, as basalt fibers begin to melt only when the temperature exceeds 1000 ° C.

- This moisture resistant materialwhich has, besides, excellent heat and sound insulating properties, eliminates the need for builders to perform moisture insulation in hinged facade systems.

- Another advantage of the mineral wool "Venti Butts" is ease of installation and savingsreached on the glue for its fasteners. This rigid material is conveniently cut into strips and fragments of the required size, which makes it possible to successfully solve the problem of fitting angles and forming joints. Because of this, the material is excellent for thermal insulation of facades that have a complex architecture.

- Due to its fibrous-porous structure Rockwool insulation is quite permeable material, which prevents the occurrence of accumulations of fungi and mold under such a coating, the service life of which, without compromising its useful characteristics, reaches 50 years.

How to make installation Rockwool "Venti Butts", learn from the following video.