Mineral wool for ceiling insulation

The warmth in the house is a guarantee of its coziness and comfort. To maintain the high temperature of the air in the living room, it is necessary to warm not only the walls and the floor, but also the ceiling. The most famous material for its warming is mineral wool. Due to its relative cheapness, ease of use and durability, this material is very popular even among experienced builders.

Special features

Minvat is a universal remedy for insulating ceilings of various types of buildings and structures. The material has a number of significant advantages that allow him to occupy a leading position among other options for warming.At the same time, it should be remembered that the insulation process must be carried out by professionals or people who have prepared and studied the necessary materials. And the procedure itself must be thorough and carried out with great care and accuracy.

The fact is that even the smallest mistake made during insulation can cause a decrease in the effectiveness of mineral wool. That, in turn, will lead to additional financial losses, and maybe even ruin your roof. Therefore, before proceeding to the insulation of the ceiling, you should study all the necessary recommendations and tips to avoid material and time costs.

Advantages and disadvantages

Like any other material, mineral wool has a set of advantages and disadvantages. Let's try to figure them out.

Advantages of mineral wool as a heater for the ceiling:

- Affordable and affordable prices. Usually repairs are expensive. Therefore, a nice bonus will be the opportunity to save the family budget. Especially if this economy does not harm quality.

- Ease of use. Mineral wool is a pleasure.As a rule, it is produced and sold in the form of rolls and plates, which makes its operation as simple and convenient as possible.

- High fire resistance. A fire in the house is an unpleasant affair, but possible. Therefore, the safety of materials used for its construction, insulation and finishing - one of the most important qualities. Not only that the mineral wool itself is fire-resistant, it also prevents the spread of fire into the depths of your home.

- Low weight. To warm the ceiling is not an easy thing. For the work will require physical fitness and strength. Especially if you decide to produce insulation from the inside. A low mass of mineral wool will greatly facilitate the task.

- High density The material has a fibrous structure, which provides high-quality not only thermal, but also sound insulation, which will be an additional pleasant bonus.

- Pest resistance. The composition of the insulation does not allow it to wind up in it a variety of unwanted "guests" (bugs, mice and other rodents).

- The possibility of long-term use. Unlike some other popular heaters, mineral wool will serve you in the long run.Once having used mineral wool as a material for home insulation, for many years you will enjoy its productive action.

- No unpleasant smell. This quality of material allows it to be used in any residential premises. It is suitable even for children's rooms and rooms where people with allergies and odor intolerance live.

- Ecological safety and cleanliness. Especially important indicator of quality in the modern world. If you care about the state of your environment, then mineral wool is undoubtedly the right choice.

- High vapor permeability. In the warm season, this advantage will protect the building from overheating, and in cold weather it will contribute to the removal of excess fumes on the street.

- Fortress. Insulation is not amenable to mechanical loads of varying intensity.

However, nothing perfect exists. This also applies to mineral wool, so now consider the shortcomings of the material.

The disadvantages of mineral wool:

- Does not tolerate structural transformation. Mineral wool - a building material that can not be crushed and tamped. This is due to the fact that during the compaction of fibers, its insulating properties are significantly reduced.

- Does not tolerate moisture.Most often for thermal insulation of the ceiling mineral wool is used in conjunction with additional materials, such as foam and polyethylene in the form of a film. Such "cooperation" allows you to preserve the properties of wool, prevent it from getting wet and ensure effective and long-lasting thermal insulation of your room.

As you can see, the advantages of mineral wool as a means for insulating ceilings are much more than disadvantages. That is why a large number of construction workers choose this material.

Thickness

The thickness of the mineral wool is one of the most important quality indicators. In order to correctly determine the choice, carefully study the packaging, or better - consult with a specialist in a store or a construction company. In general, the main thing you need to decide is the number of layers with which you will put insulation and the climate of the area in which you live. The thickness of mineral wool varies on average from 20 to 200 mm. Usually for thermal insulation of residential buildings they use a 150 mm thick mineral wool. However, there are several options. So, for thermal insulation of a flat horizontal roof, 30 mm will be enough, and for a pitched one, about 200 mm will be needed.

An important parameter in the selection is the building material of which the ceiling is made.Thus, in the situation of the presence of concrete floors, mineral wool less than 100 mm thick should not be used. For those buildings that have a heated attic, the material may be thinner - up to 80 mm.

Which one to choose?

The modern market is filled with varieties of mineral wool. And they differ not only by the manufacturer and price, but also by the initial raw materials (glass, stone, slag).

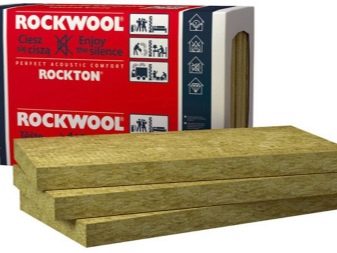

Consider the main types:

- Slag wool, in the majority, use at the industrial enterprises: factories, factories, combines. This type of wool is best used for thermal insulation of horizontal surfaces that do not have a large slope.

- Glass wool - material that can irritate your airways and your skin due to the sharpened microscopic particles from which it is composed. Most often, this type of wool is used for thermal insulation of wooden structures and buildings.

- Stone wool - the most common form. It is produced and sold in large quantities and is suitable for a wide range of tasks, being almost universal.

Also, when choosing a mineral wool one should pay attention to the place of its storage,which should be indicated on the packaging (ideal - canopy). Do not get wet or damp material.

How to lay?

Using mineral wool, you can insulate the ceiling in any room (for example, in your private house) in two ways: from the outside and from the inside. External insulation is considered more economical, convenient and easy to implement, but the insulation from the inside will be more efficient. Consider step by step both options for thermal insulation of the room with their own hands.

External

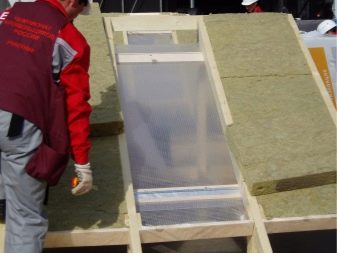

Before starting the work, the insulated surface must be thoroughly cleaned, getting rid of debris, dirt and other unnecessary elements. As mentioned earlier, it is advisable to use other materials with mineral wool in order to prevent it from getting wet. Therefore, for the next step you will need any waterproofing. The simplest is plastic film. The film is cut into strips that should be put between the beams, securing the ends. After the procedure of fixing the film, you can use the mineral wool In case you decide to use an additional layer of protection against getting wet, you can put foam layers on the plastic wrap and only then use the main insulation - cotton wool.The installation technology of mineral wool is quite simple: it needs to be fastened tight enough so that no gaps or gaps are formed.

Insulation should be laid in several layers. Especially useful this advice will be for residents of cold areas. The joints of the layers should not be the same. The last layer must cover the ceiling beams. This is necessary so that heat does not go out through the tree. After you managed to lay the insulation, you should fix another layer of the chosen waterproofing (plastic film). The final step is to cover the insulation. You can use any coating. Most often, preference is given to a tree.

Interior

The internal method of insulating the room is somewhat more complicated. However, nothing is impossible. The first step is quite simple and is similar to the first in the previous version: you need to lay a layer of vapor and water insulation. Then we construct a wooden base, on which the hinged ceiling will later be located. Between the wooden sides of the structure we lay mineral wool tightly. If you want to fix more securely, then you can use nails and wire. We drive nails of mineral wool on both sides of the seam, zigzagging the wire.

Thus, mineral wool can be effectively used for warming even very cold concrete or stone premises, instead of other heaters, for example, expanded clay.

Tips and tricks

When using mineral wool like any other material, A few simple rules should be followed:

- Wear heavy gloves, a respirator, goggles and protective clothing during work.

- It is best to cut mineral wool layers with a serrated blade knife or a special hacksaw for metal.

- During insulation, special attention should be paid to ensure that cotton wool does not cover the ventilation hole.

- The layers of mineral wool should be closely interconnected.

- The layers of mineral wool should be wider than the distance between the rafters. Pay attention to this in the measurement process.

- Before work, check the operation of communication systems.

- Rafter construction must be strong, check this point in advance.

- For better processing of the heat-insulated surface, it is necessary to use antiseptic agents.

How to warm the ceiling with mineral wool using mineral wool, see in the video.