Ecowool and mineral wool: which insulation should I choose?

Insulation is an essential element for creating comfortable temperature conditions in the room. Such materials are used for finishing residential, commercial and public buildings. The market offers a huge variety of options with individual properties and characteristics. Among the rich assortment are mineral wool and ecowool, which are at the peak of popularity. Consider their differences and find out which of the materials is better to use under certain conditions.

Composition and styling

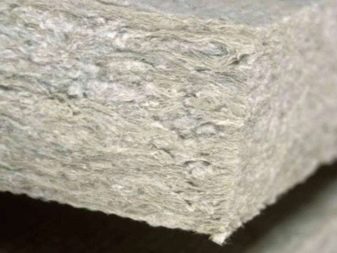

Ecowool is a material that is obtained as a result of recycling waste paper. The product has the form of dense granules. Insulation is mounted in two methods: dry or wet coating.

At registration of the vertical planes it is recommended to use manual laying. Using ecowool, you can reliably fill cracks, gaps and other cavities in structures for a long time.

Minvat (basalt insulation) is not a specific product, but a separate group that includes three positions. It is produced in the format of mats and rolls, which are conveniently laid on different surfaces.

- Glass wool. This finishing material is made of fiberglass, whose thickness varies from 5 to 15 microns. The length is also different and can be from 15 to 50 millimeters. The product can be made in roll or plate form. The practical form provides convenient installation both on horizontal, and on vertical surfaces.

- Slapped. For its manufacture uses blast furnace slag and formaldehyde. The last component is hazardous to human health. The material can not be used on open metal substrates due to the increased acidity of the main component of the insulation. Otherwise, corrosion begins to act. One of the features of the material is the ability to absorb moisture,because of what to lay slag in wet areas is impractical. Due to the affordable cost and efficiency of the material is in great demand. It is recommended for use in industrial and production facilities.

- Stone cotton wool. The product is made as a result of processing basalt rocks. Also, manufacturers mix hydrophobic additives. Insulation is not pricked like glass wool, thanks to which it is more convenient and safe to work with it.

Specifications

In the process of comparing two heat insulators, it is necessary to evaluate the performance characteristics as well as the individual properties of the goods.

Thermal conductivity

The main purpose of insulation is to maintain the optimum temperature inside the building due to the complete prevention or partial reduction of the air exchange process between the street and the building. Each of the two materials has its own coefficient of thermal conductivity. The higher its value, the better the efficiency.

Indicators:

- ecowool - from 0.038 to 0.041;

- mineral wool: glass wool - from 0.03 to 0.052; slag wool - from 0.46 to 0.48; stone wool - from 0.077 to 0.12.

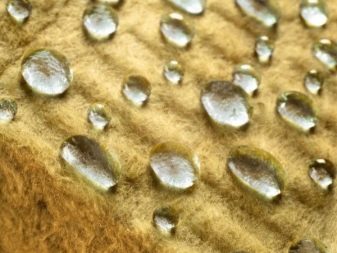

The first option does not change its indicator in the process of interaction with moisture. Dampness easily evaporates due to the special structure of the fibers, and the material returns the original properties and appearance.

Other insulation behaves completely differently. Even at the slightest interaction with moisture, the effectiveness of mineral wool decreases significantly. Finishing begins to freeze, and the form is restored with difficulty over a long period of time.

You will learn more about how heaters behave when interacting with moisture by watching the following video.

Air flow capacity

Of great importance and air. It means the effectiveness of insulation in strong gusts of wind. A lower figure indicates a better preservation of heat inside the building.

- Ecowool - 75 × 10-6 m3 / m * s * Pa.

- Minvata - 120 × 10-6 m3 / m * s * Pa.

Flammability

Fire resistance is an important factor in terms of fire safety. When describing this operational characteristic, it is necessary to understand the difference between burning and smoldering.

Minvata smolders, but does not ignite. In the process of smoldering, the material emits substances that have a detrimental effect on the health of people and animals.Other heat insulation melts under the influence of high temperatures. Therefore, the product should not be laid near sources of open fire.

Life time

As a rule, various types of buildings (residential buildings, commercial buildings, public institutions, etc.) are built for many years.

It is advisable to use durable and reliable materials for finishing in order not to spend money on frequent repairs.

The life time of ecowool varies from 65 to 100 years depending on the manufacturer and the quality of the material. Also important is the correctness of the installation process and the organization of the ventilation of the working layer.

Mineral wool is not so durable. The average period of her service is about 50 years, provided that all recommendations for packing and use are followed.

What is different installation of insulation?

The use of mineral wool is limited due to the complicated installation procedure. This material is practically not used for lining complex shapes and unusual designs. The difficulty lies in the fact that the mineral wool is sold in the form of panels, rolls and blocks, and in the process of installation used adhesives.

When using ecowool, the type of base, as well as the condition of the walls, does not really matter. The product can be applied to the surface or blown into the cavity. The time spent on work depends on the method of application. Mechanical is much faster, but it requires special tools, as opposed to the manual method.

Mineral wool must be used in conjunction with the vapor barrier due to the negative interaction with moisture.

Additional finishing has a direct impact on the life of the insulation. With proper use of the vapor barrier layer, mineral wool can be laid inside or outside the room. Ecowool is laid without a protective layer. Additional cladding can only be used in individual cases.

Price

The cost of finishing material plays an important role in the final choice of product. Ecowool is much cheaper than mineral insulation. The difference in price can be from 2 to 4 times depending on the manufacturer and the individual mark-up of the store.

Purchase insulation only in reliable outlets that offer a certified product at a reasonable price.To verify the quality of the material, require the presence of the appropriate certificate.

Conclusion

To make the right choice, you need to have a general idea of each material. The article reviewed the technical characteristics and features of two heaters of various types. Using the above information, you can make a choice, given the operational capabilities, the cost of materials and other aspects.

Ecowool is ideal if the main criterion for selection is the fit of the trim to the base and the absence of shrinkage. If speed and ease of installation are more important for you, then it is recommended to make a choice in favor of mineral wool. The main advantage of this insulation is that additional equipment is not required for its installation.