Technical characteristics of insulating mats

In the construction and repair of the house an important component is to conduct a competent insulation. An important point in this issue is the choice of insulation. The range of such materials in the modern market is quite wide. It also presents universal products that are suitable for complex thermal insulation of buildings. One of them are insulating mats.

Description and specifications

Today, insulation mats are very popular among consumers. They have an affordable price, do not create problems during installation, which can be performed independently, and also have a set of high technical characteristics.

There are ordinary and piercing mats.The firmware gives additional strength to the products. Such materials may have a galvanized steel mesh, and reinforced glass fiber-based foils are glued to one of the sides. Experts note that when using insulating mats, heat loss is reduced by about a third.

With regard to the technical characteristics of the product, it should be noted that in the presence of the outer shell of glass wool, its heat resistance can be up to 500 degrees. The standard thickness of insulation is 18 millimeters. Products have springs and other components that are made of stainless steel, which guarantees their strength and long-term operation. In addition, other types of clamps can be used.

Regardless of what material the products are made of, they are most often used for roof insulation. More dense mats can be used to warm the floor, but their composition should be exclusively basalt fiber. Insulators of glass wool are used when working with ceilings, including hinged. Proshivnye mats made of mineral wool are popular for thermal insulation of roofs with a significant area, for example, in entertainment centers.

Species

Heat-insulating mats can be divided into 2 groups depending on the material of manufacture. They can be mineral wool and fiberglass. Consider these species in more detail.

Basalt mats

They are also mineral wool-based mats. Today it is the most popular thermal insulation material. The base fibers are interwoven and have a crystalline structure.

Mineral wool products can be made both in the form of mats and in the form of rolls. Mats are thicker and more elastic, their thermal insulation properties are better. In this case, the mats are used when working with loaded structures.

This material is excellent for thermal insulation of plastering and ventilated facades, as well as roofs, floors, ceilings, walls and balconies. Basalt mats have a low thermal conductivity, do a good job of soundproofing a room, and are resistant to rotting, mold and mildew. In addition, upon contact with fire, they will melt rather than burn. At the same time, mats made of mineral wool do not create problems during installation, have an affordable price, and their service life is about 50 years.

If we talk about the shortcomings, it is impossible not to note the lack of moisture resistance. In this case, this is an important point, since when a liquid enters the product, it loses its insulating properties.

Therefore, when working with such mats, it is necessary to take into account that their installation must necessarily include the installation of waterproofing and vapor barrier materials. It is necessary to protect the insulation.

Fiberglass mats

Mats on the basis of glass wool are very popular when carrying out internal work on the insulation of the room. They are often used for insulation of interior partitions. When using glass wool products in office premises, they are recommended to be sewn into plasterboard walls. At the same time, it is possible to achieve not only excellent thermal, but also sound insulation of the required area.

One of the main differences and an undoubted advantage can be called a small weight of fiberglass mats. This makes it possible to use these materials when working with suspended ceilings.

The use of glass staple fiber mats and slabs is currently gaining popularity.Materials are manufactured using the latest technologies, their technical characteristics are higher. In addition, these mats are much more convenient to transport, they do not prick and do not cause inconvenience during tactile contact.

All pierced mats can be divided according to the features of their design. They can be on a metal grid, fiberglass or fabric, plastic wrap or without lining.

Advantages and features

Among the undoubted advantages of mats of any kind, it is worth noting that the financial costs of space heating are significantly reduced. Products are non-toxic, they do not emit harmful substances during operation. Materials withstand high temperatures and do not lose their qualities and properties even with their long-term exposure. In addition, the room heats up much faster and heat is stored for a long time.

Products made from any kind of materials do not actually burn or ignite. They are environmentally friendly and do not harm health. They can be applied plaster and paint mixtures, as well as to carry out finishing in other ways.

Quite often there is a question about the need to use insulation mats, if you plan to put a heated floor in the room. It should be noted that in the absence of an insulator the heat will go to the concrete base, and this will necessarily affect the financial costs of the user.

Foil mats are one of the options for warming. They are based on polyethylene foam, and the foil is applied to one of the sides. Also foil mats can be equipped with a protective coating.

This type is advisable to use if the floor is the main source of heat in the room. In this case, the use of flat polystyrene foam mats, which endure mechanical stresses and are practically not deformed, would be an excellent option.

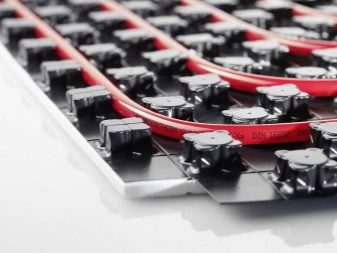

Also popular among consumers are profile mats. Their basis is dense polystyrene foam. The surface is equipped with projections of a cubic or cylindrical shape. They can be as simple as with the application of a vapor barrier film.

Subtleties of installation

If the roof has rafters as a bearing base, the insulation must be laid between them.An important point is the equipment vapor barrier, as well as waterproofing material. Condensate may form on surfaces, and contact with it or other liquids becomes detrimental to basalt mats and leads to loss of their performance properties. The protective film can be easily fixed on the base with a conventional construction stapler.

The outer side of the insulation is covered with a waterproofing device. It must be placed on the crate attached to the rafters.

If it is necessary to warm the roof covering on a large building, the mats should be laid in a staggered manner and in 2 layers. A ruberoid is placed over them.

If basalt mats will be used for external wall insulation, for their long-term operation, you need to equip a ventilated facade. In this case, before the work should pay attention to weather conditions. Rain and high humidity can affect materials. When finishing it is necessary to take into account that These products are not recommended for use in suspended ceilings due to their severity.

Summing up, it is worth notingthat insulating mats of all kinds are an excellent material for warming a room. In addition, their installation is quite simple, and it can even be done independently. For this, the main thing is to follow the instructions and basic recommendations of specialists.

Review of Rockwool basalt-based thermal insulation boards in the video below.