Basalt insulation for walls outside the house: features of using stone wool

Using basalt insulation for external insulation of the house is a simple and effective way to increase its efficiency. In addition to thermal insulation, using this material will be able to increase the sound insulation of the building. Among other technical characteristics - fire resistance, environmental friendliness and durability of insulation.

What it is?

Insulation made from the finest fibers of mineral origin, called mineral wool. Depending on the basis of the composition, it has several varieties. The highest heat and sound insulation qualities, as well as environmental friendliness and fire safety is demonstrated by stone wool insulation.

Basalt wool is a variety of mineral wool insulation, its technical properties are significantly superior to its main types. Basalt insulation consists of fibers melted and elongated into filaments. Stirring in a chaotic manner, they form an airy, but durable and warm material.

Between the fibers accumulate a huge number of air bubbles, which provide a heat-insulating effect, and also demonstrate the ability to reflect and absorb sound. The name of the heater was due to the fact that the fibers of the material are obtained by processing rocks. Stone wool is also called "basalt" and "mineral."

Varieties of basalt insulation can be determined by its density and diameter of the fibers used. On the basis of density, soft, semi-rigid and hard cotton wool is isolated. The thickness of the cotton wool is from 1 micron (micro thin) to 500 micron (coarse fibers).

The form of release of material - front plates, produced in 2 dimensional versions: 0.5 by 1.0 m and 0.6 by 1.2 m. Thickness is 5–15 cm. 10 cm thick plates are considered to be the most popular for external insulation of a country house. .Less common is the analogue in rolls: it is less dense and at the same time susceptible to deformation.

The material has a wide range of applications. If we talk about the insulation of exterior walls, it fits both under the "wet" and under the "dry" types of facades.

How to produce?

The progenitor of modern insulation steel threads found in Hawaii near the volcano after its eruption. Locals have found that these light fibers, when folded together, improve the thermal efficiency of the dwellings, are not afraid of water, and are not torn. Technically, the first basalt cotton wool could be obtained in 1897 in the USA. However, at that time it was produced in open-air shops, therefore the smallest particles of basalt raw materials penetrated into the respiratory tract of workers. It almost did not become a failure to produce material.

After a while, there was a way to differently organize the production process and protect employees. Today, basalt wool is made from rocks that are heated in furnaces up to 1500 C. After that, the threads are drawn from the molten raw material. Then fibers are formed, which are impregnated with special compounds to enhance the technical properties of the insulation and are laid in chaoticokay

Advantages and disadvantages

Insulation based on stone wool has many positive properties.

- Durability. Long service life (up to 50 years, according to the manufacturer) allows you to forget about the need to warm the facade for a long time. If the installation rules are observed, the period of operation can be extended for another 10–15 years.

- Heat efficiency. The porous structure of the material ensures its high insulation performance. Its use allows you to maintain a favorable microclimate in the house: warm in the cold season, pleasant coolness in the summer heat. The material has a low thermal conductivity, which is 0.032–0.048 W per meter-kelvin. Polystyrene foam, cork, foamed rubber have a similar value of thermal conductivity. Ten centimeters of basalt insulation with a density of 100 kg / m 3 able to replace a brick wall 117–160 cm thick (depending on the type of brick used) or a tree whose thickness is almost 26 cm.

- High sound insulation performance. In addition to high thermal efficiency, the material has enhanced sound insulation characteristics. This is also due to the characteristics of the composition and structure of the material.

- Fire resistance. The material is considered to be non-flammable, as it withstands temperature rise up to 800-1000 C.

- Vapor permeability. Vapor permeability of the material ensures condensate discharge. This, in turn, ensures the safety of the technical properties of insulation, the absence of high humidity in the room, protection from mold and fungi both inside the building and on the surface of the facade. Permeability of permeability - 0.3 mg / (m · h · Pa).

- Chemical inertness, biostability. Stone wool is characterized by chemical passivity. When applying it on top of metal products, you can be sure that they will not be exposed to rust, and mold and fungi will not appear on the surface. In addition, stone fibers are too tough for rodents.

- Ease of use. Several options for the dimensions of the sheets, as well as the possibility of cutting the material greatly simplify its installation. Unlike glass wool, basalt fibers do not prick and do not have the ability to penetrate the skin.

- Moisture resistance. Due to this property, drops of moisture do not settle inside the material, but pass through it.In addition, cotton wool has a special hydrophobic impregnation, so it literally repels moisture. The moisture absorption of the material is at least 2%, which makes it an optimal insulation not only for the facade of the house, but also for the walls of the sauna, bath and other objects characterized by high humidity.

- No deformation. The material is not deformed and does not shrink, which is a guarantee of maintaining the technical characteristics throughout the entire period of operation.

- Environmental friendliness. Due to the natural composition of the material is non-toxic. However, the buyer should be careful: sometimes manufacturers add slags and additives to the composition of the basalt heater to reduce the cost of the material.

It should be remembered that they burn at a temperature of 400 C, and the material with such additives has the worst performance characteristics.

The disadvantage of insulation can be called a high cost. However, if they insulate the facade of the building, in the future you can save on its heating. Like all mineral wool materials, stone wool during cutting and during installation forms the smallest dust that irritates the mucous membranes of the upper respiratory tract.To avoid this allows the use of a protective mask.

Finally, due to high vapor permeability basalt insulation is not recommended for finishing the basement and basement of the house.

How to choose?

For the walls of a country house, basalt cotton wool of average density (semi-rigid material with a density of at least 80 kg / m3) 8–10 cm thick is sufficient. Pay attention to the location of the fibers. Chaotically located threads provide the best sound and heat insulation qualities in comparison with horizontally or vertically oriented fibers.

In order to improve the insulating properties, you can purchase foil analogue. On one side, it has a foil, which not only reflects the thermal energy, but also has a more reliable hydroprotection, allows to reduce the thickness of the insulation used. In addition, the foiled version of insulation is suitable for regions with high humidity, for houses located near water, as well as for brick walls, because it is characterized by improved hydrophobicity.

The latter property is especially valuable for a wet facade, since a too thick layer of insulation may not firmly adhere to the walls, creating an excessive load.

For a frame house, in the walls of which the presence of a layer of insulation is already expected, you can use cotton wool of a lower density - 50 kg / m3. For the northern regions, as well as for operation in extreme conditions, it is recommended to use a solid stone wool mat. It has a wider temperature range of operation.

When buying stone wool, preference should be given to well-known manufacturers who have received a positive assessment of buyers. Among them: the products of the domestic company TehnoNIKOL, as well as products manufactured under the French brand Isover and the Finnish trademark Paroc. Pay attention to how the product is stored: it must be in the original packaging and wrapped in shrink film. Packaging must not have holes and damage. It is unacceptable to store products under the open sun - only under a canopy.

When buying insulation in a cardboard box, make sure that it is not exposed to wet. Dirty stains on the packaging, different density of cardboard - all this may indicate the ingress of moisture. The purchase should be abandoned, since the material is highly likely to lose its technical properties.

Important point: the glue used to connect the stone wool and the foil layer reduces the fire resistance of the finished product. To avoid this, purchase of pierced basalt materials will allow.

Subtleties of application

Stone wool is usually used for outdoor insulation, which is caused not only by high thermal efficiency and moisture resistance of the material, but also by the possibility to avoid reducing the floor space, which is inevitable when wall cladding from the inside.

To insulate the material outside, choose a dry warm day. The air temperature should be + 5 ... +25 С, the humidity level should not exceed 80%. It is desirable that the sun's rays do not fall on the surface being treated.

Regardless of whether basalt wool is fixed under the plaster or curtain facade, it is correct to start laying with the preparatory work.

Training

At this stage it is necessary to free the facade from cement drips, protruding elements, pins. It is necessary to remove all communication: pipes, wires. Be sure to eliminate the gaps and cracks through the cement mortar.

After it is possible to achieve evenness and smoothness of the surface, you can proceed to the primer of the facade.It should be applied in 2-3 layers, allowing the previous to dry before applying the next.

After the primed surfaces are completely dry, proceed to the installation of the frame. It consists of metal profiles that are attached to the wall with dowels.

Installation

Technology laying basalt insulation depends on the type of facade. If the facade will be finished with plaster, the plates are mounted on a special adhesive composition. The latter is pre-diluted with water in the proportions indicated on the package, after which it is thoroughly mixed.

Glue is applied to the surface of the insulation, after which the material is pressed tightly against the wall. It is important to install and smooth it before the glue is fully set to the wall and cotton surfaces. After the previous product is fixed, the next plate is laid.

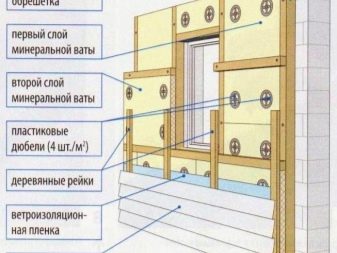

For additional reinforcement in the center and on the sides of each plate of insulation, holes are made into which dowels are inserted. After the wool is laid and fixed on the surface, it is covered with a thick layer of adhesive composition, and then the reinforcing mesh is pressed into it.The laying of the latter starts from the corners, for which special reinforcing corners are used. After the corners are strengthened, after about a day, you can fix the grid along the rest of the facade.

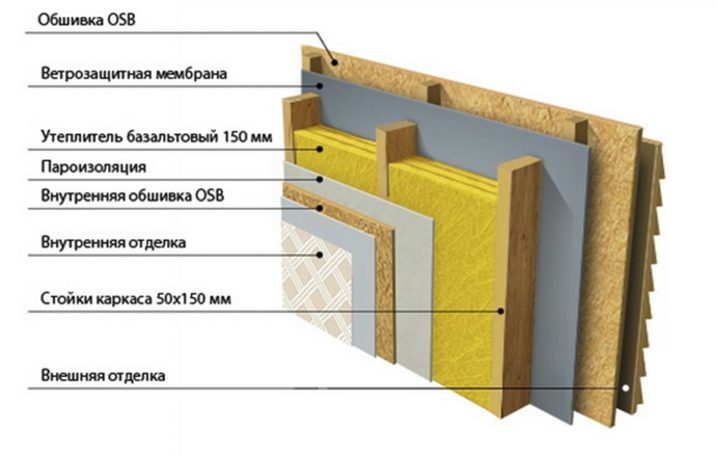

After another day you can begin to plaster the walls. First, a rough finish is applied, which is not perfectly smooth. However, gradually, layer by layer, the facade becomes more even. When organizing a mounted material with your own hands, after installing the frame on the wall, a hydro-protective film is attached, and on top of it - layers of stone wool. They do not need gluing - they are immediately fixed with dowels.

A windproof membrane is used to protect the insulation from wind and precipitation; it is laid on stone wool. It is important to fix with one dowel at once 3 layers: windproof, insulation and hydroprotective. The thickness of stone wool is selected on the basis of climatic conditions and structural features of the structure.

Finishing

Finishing under the “wet” facade begins with the painting of plastered walls. For this, ground paint is used. For its better adhesion to the surface of the walls, the latter are processed with fine emery paper.Finishing performs two functions: protective and decorative. The plastered facades made by the “wet” method are widely used. Dry plaster mixture is diluted with water and applied to the prepared walls.

Corners, window and door openings and architectural elements are made using additional structures. In order to improve the thermal efficiency of the building, they resort to the organization of a ventilated facade, which can be mounted or carried out with the use of building mixtures. A feature of the ventilated facade is the air gap between the trim and insulation.

Most mounted facades have such gaps, the general principles of their organization are described above. For the organization of a “wet” ventilated facade, the insulation after installation is also closed by a vapor-vapor barrier windproof material. A crate is filled to the walls, onto which plasterboard sheets are fixed. It is important that an air gap of 25–30 cm is maintained between the layers of stone wool and gypsum sheets. Then the surface of the gypsum cardboard is primed, the joints are carefully sealed, compared with the rest of the sheet.After drying, the primer is applied plaster or paint the surface.

In addition, plastered and primed facades can be painted using acrylic-based facade paints.

Suspended construction involves the use of vinyl siding, porcelain tiles, slabs of artificial or natural stone. They are mounted on a frame made of metal profile and fixed with dowels. To provide increased reliability of the hinged facade, its wind resistance and the absence of gaps between the individual elements allows the presence of a locking mechanism on the panels or slabs for finishing.

In the next video you can learn more about the process of warming the walls of the house outside.