Penoplex 30 mm: features and specifications

Comfortable living of a person in a new house depends on many factors, and thermal insulation plays a significant role in this matter. The modern market offers a huge amount of materials for insulation, differing in characteristics and cost. The most effective, as shown by the practice and consumer reviews, is Penoplex 30 mm.

What it is?

Penoplex (extruded polystyrene foam) was first introduced to the public in the United States more than 50 years ago. The material quickly gained the trust of customers due to its low thermal conductivity and reasonable price.

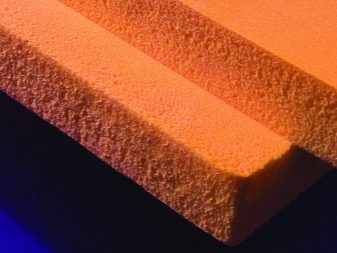

At the stage of creating this product, polystyrene granules are pressed under the influence of pressure and high temperature., it uses a special catalytic substance carbon dioxide and light freon for foaming mass. The finished mixture resembles thick pastry cream. After mixing and foaming, all the slurry passes through special nozzles of the extrusion unit and goes outside. Freon evaporates, and the resulting voids are filled with air.

Thanks to such a complicated technological process, the finished product is obtained in small-pore, and therefore, durable and light.

All cells with air are isolated from each other, and their diameter does not exceed 0.1–0.2 mm. The standard size of the Penoplex panel of 30 mm is 585x1185 mm. The dimensions of the plates of this product affect the number of sheets in the package. This criterion also affects how much m² of thermal insulation is contained in one bundle.

As a rule, one package of Penoplex is enough to isolate 10.08 squares of the surface.

Advantages and disadvantages

Thermal insulation of the new generation “Penoplex” 30 mm in its technical characteristics in many ways surpasses the previously popular mineral wool and foam plastic.

It has excellent advantages.

- Excellent thermal insulation. According to specialists, Penoplex 30 mm replaces about 750 mm of brickwork. The low thermal conductivity of the material can significantly save money, because when working on thermal insulation, you can use a thinner layer of “Penoplex” than the same foam.

- High strength. This property allows expanded polystyrene plates to cope even with large vertical loads. Therefore, Penoplex 30 mm can be purchased for plating plinths and foundations, exterior walls.

- Excellent insulation. Extruded polystyrene foam can be used for soundproofing premises. With its help, they successfully equip home studios or get rid of street noise that irritates the nervous system. Extrusion partition "eats" up to 41 dB, giving the house a welcome calm and silence.

- Moisture resistance. The less insulation allows steam and absorbs moisture, the better it copes with its functions. Penoplex, 30 mm thick, has zero moisture absorption, so it works like a thermos on the walls.

- Low weight. The plates of “Penoplex” 30 mm are lightweight, which allows them to be mounted quickly and save on transportation.

- Absolute security. Extruded polystyrene foam is non-toxic, has no chemical smell, and therefore harmless to human health and the environment. From some brands of extrusion produce even children's toys. Harmful impurities, such as soot, slag, freon, are absent in the product, which means that it is possible to speak about the environmental friendliness of the plates.

- Long service life. Low quality foam crumbles from the slightest impact on it. Even the most expensive mineral wool over the years begins to subside and wrinkle, and the insulation “Penoplex” 30 mm, even after 50 years of service, will not lose its original characteristics.

- Low thermal conductivity. Thanks to microcells extrusion product is a material with low thermal conductivity. In a house with such insulation, it will not be hot in summer, and in the cold season it will not be cold.

- Temperature rangeat which it is possible to work with Penoplex of 30 mm makes from-50 to + 75ºС.

- Wide scope.

The material is easy and convenient to install.

The only drawback of extruded polystyrene foam is that this product does not tolerate the effects of organic solvents, for example, acetone.Such aggressive chemicals soften the plates, destroy their shape and even completely dissolve.

Application area

Heat-insulating plates of “Penoplex” 30 mm are used for thermal insulation of walls, roofs, foundations, basements and floors in private possessions. As well as the wide application of extrusion products found in the insulation of balconies, loggias in urban high-rise buildings.

"Penoplex" 30 mm warming fencing structures, garages and other types of outbuildings.

When laying the plates between the working surface of the insulating material and the cladding surface, no “cold bridges” are formed, which creates an optimal microclimate inside the living room. The ambient temperature is always pleasant to find a person in any weather conditions.

Due to the high strength, Penoplex 30 mm can withstand high loads both horizontally and vertically.

In any condition, it is not deformed during the facing work. The plates of extruded material do not absorb moisture; therefore, the products are successfully used for covering baths and saunas, wine cellars, pools and other premises where the humidity level is constantly high.If you need to insulate the apartment, make repairs in a country house, or perform waterproofing of the foundation, you do not need to overpay when buying Penoplex of more expensive series.

For internal work, Penoplex extrusion of 30 mm is sufficient. The cost of packing this product will be significantly lower compared to the same “Penoplex” 100 mm, in addition, a smaller thickness does not “eat” the useful area of housing.

The plate of Penoplex heater 30 thick will be useful at arrangement:

- warm floor systems;

- waterproofing basement and foundation;

- any type of roof and ceiling;

- partitions or "well" masonry walls;

- garden paths.

Stamps

In the modern market you can find several series of Penoplex 30 mm.

- "Roof". The main purpose - the device of the insulation layer of any type of roofing. The main advantage of these plates is high strength and the presence of anti-foil (anti-flammable impurities) in the composition.

- "The foundation". It is used for internal and external lining with insulating layer of enclosing structures. If there are no special requirements for this series, you can safely use it for warming walls, floors, roofs and plinths.

- "Facade". It is considered the best option for the insulation of partitions, walls and facade surfaces. The advantage of these plates lies in the ability to self-extinguish and a rough surface, and therefore to better adhesion of glue and plaster mixture.

- "Comfort". According to experts, this insulation material is suitable for almost any need: insulation of loggias and balconies, walls, flooring, insulation of the foundation, engineering communications and even garden paths.

Cost of

The cost of the insulation material “Penoplex” 30 mm depends on who made it, on the dealer selling the plates on the market, on the selected series and the size of the sheet. Packaging of insulation plates 30 mm thick, consisting of 12 sheets, will cost customers 950 rubles and above.

The cost may be lower if you buy Penoplex in bulk and in bulk. Penoplex is sold only in packages. This facilitates the process of its transportation. Each pack of 30 mm thick insulation contains up to 16 plates (the number depends on the size of the product). On the pack, as a rule, there is a table for calculating the required number of plates.

See how to insulate the walls of the penoplex, see the following video.