Penoplex: what is this material, where is it used and how is it mounted?

If earlier the assortment of heat-insulating materials was not rich enough, then today the buyers are faced with a wide choice of heaters with different properties and performance characteristics. This means that a homeowner with any budget can choose the right option. Today Penoplex is rightfully recognized as one of the most popular materials, which is in great demand and occupies a leading position in the market of thermal insulation coatings.Today we will examine in detail what it is, find out where it is used and how this popular insulation is mounted.

What it is?

Surely every person at least once in my life heard about such building material as penoplex. However, not every consumer knows what lies under this name.

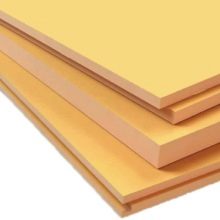

Penoplex is a well-known trade name for high-quality extruded polystyrene. Today this material is in the lead in the market of heaters. They are often covered with walls, ceiling structures, roofing foundations and even floors.

Features and production

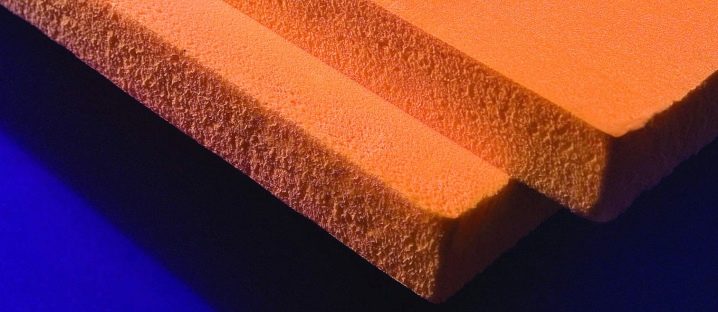

Penoplex is a high-quality polystyrene foam. This type of material is obtained by extrusion.

A similar production process was developed more than half a century ago in the conditions of American laboratories. Thus, a completely new material, whose structure consisted of closed microscopic cells, appeared. From the very beginning, their sizes did not exceed 0.2 mm. In a single structure, these components created a neat and uniform surface without potholes and drops.

In the granules of this polymer there is a special additive that has a foaming effect. This component is connected to the granules under pressure or under conditions of heating to a certain temperature. The result is a mass, which is then passed through an extruder.

Foaming components (as a rule, they are represented by carbon dioxide or a mixture of light freon) are non-toxic and absolutely safe from an environmental point of view. In addition, these components are not flammable.

When the manufacturing process is completed, all auxiliary components are replaced with air from the environment.

The result is a high-tech insulating material with excellent performance characteristics. With its use in the home it becomes much warmer and cozier - a comfortable microclimate is created that you do not want to leave.

The main features of Penoplex are:

- low level of heat conduction;

- good strength characteristics;

- minimum level of moisture absorption.

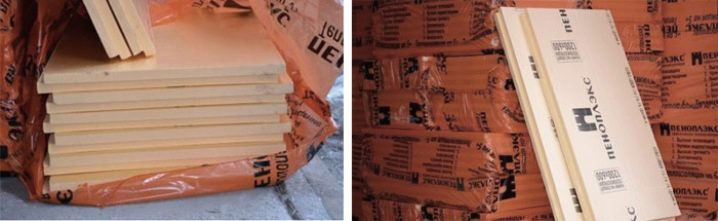

As a rule, this insulation is packed in a film that protects it from the ingress of aggressive sunlight.Thanks to such packaging, such material can be safely stored while being in the open air. However, it is worth considering that even in the presence of plastic packaging you need to additionally protect the product from ultraviolet radiation.

Under the influence of UV rays, this insulation can lose the integrity of the upper layer.

Advantages and disadvantages

Penoplex is a popular material that is in great demand. Its popularity is due to many positive qualities:

- Penoplex is a hydrophobic material.

- It is lightweight, so working with it is quite easy. Moreover, you will not spend a lot of money on transportation of this material.

- Penoplex is distinguished by excellent strength characteristics. It is not so easy to damage this material - it is not subject to the appearance of mechanical defects.

- The composition of this heat-insulating coating is anti-corrosion, so it can be safely laid on the base, consisting of a variety of materials.

- Installation of penoplex can be started in almost any conditions. You do not have to wait for the right moment to proceed to the installation of plates.

- This insulation does not attract the attention of insects and rodents, to get rid of which, as a rule, it is quite difficult.

- Penoplex is an environmentally friendly and safe material - it does not adversely affect human health.

- Penoplex is easy to install. Having the minimum set of knowledge, you can independently install this heater.

- Many buyers prefer this heater, as it has a democratic price.

- Penoplex is characterized by minimal water absorption.

- Penoplex does not cause allergic reactions.

- This material is quite strong in compression.

- This insulation is universal - modern manufacturers produce high-quality coatings designed not only for the walls, but also for the floor and roofing "cake".

- Penoplex is not subject to rotting, which once again confirms its durability and resistance to wear.

- This material has a long service life.

- Such extruded polystyrene is permissible to use both in the construction of new and in the restoration of old buildings.

Penoplex is not an ideal thermal insulation material.It has its own weaknesses, which you should also be aware of if you decide to purchase such products for your home. Among them:

- This material is combustible. It burns and actively supports burning.

- Penoplex does not withstand contact with solvents. Under their influence, polystyrene is destroyed and deformed.

- Not all manufacturers offer penoplex at affordable prices. In many stores there are expensive products.

- Another disadvantage of penoplex is its low vapor permeability (in certain situations). For example, if it is incorrect to install this material or subject it to being in adverse conditions, then condensate may accumulate in it (from the outside). That is why this material becomes susceptible to the formation of fungi and mold. To avoid such problems, the room must be provided with good ventilation, otherwise normal air exchange will be hopelessly disturbed.

- This material for high-quality thermal insulation can not boast of good adhesion. It has an absolutely smooth surface, so it is often not very convenient to glue it to the walls and ceiling.

- It is recommended to protect this heat insulating material from direct sunlight. Under their influence, penoplex may be subject to deformation or damage to the upper layer.

- To make extruded polystyrene more resistant to fire, in the production process it adds special substances - flame retardants. Materials with such additives become self-extinguishing, but when burning or smoldering, this insulation will emit black clouds of smoke with toxic compounds.

Of course, the positive qualities of Penoplex are much more than negative ones.

Many problems associated with this material can be avoided if you install it correctly.

Specifications

The main characteristics of Penoplex include:

- low vapor permeability, the coefficient of which is 0.03 W / mºK;

- high strength characteristics (both in compression and bending);

- low level of moisture absorption - no more than 0.2-0.4% by volume per day;

- low vapor permeability - the coefficient of this parameter is from 0.007 to 0.008 mg / mch · Pa);

- service life exceeds the mark of 50 years;

- resistance to burning;

- environmental Safety;

- large temperature range of application, which ranges from -50 to +75 degrees.

Due to its technical characteristics, penoplex has become a popular and sought-after material. It is difficult to damage or break. However, unfortunately, it is flammable.

Different types of penoplex belong to different classes of flammability:

- materials for warming the roof - class G3;

- for wall insulation - G3;

- for foundations - G4;

- universal insulation - G4;

- road materials - G4.

In addition, all of the listed insulating materials have different indicators of compressive density, for example:

- for the roof - 0.25 MPa;

- for walls - 0.2 MPa;

- for the foundation - 0.25 MPa;

- universal - 0.2 MPa;

- road - 0.50 MPa.

Extruded polystyrene foam boasts good resistance to various chemicals and materials. These include:

- antiseptics designed to protect natural wood;

- bitumen based mixtures;

- cement;

- lime.

Foreign materials, which include a component such as a solvent, may destroy the penoplex. Such agents soften polystyrene, which then leads to significant shrinkage.

When working with penoplex, you should avoid such mixtures:

- paint thinner;

- coal tar (and any of its derivatives);

- solvents such as acetone and ethyl acetate.

Brand and size

Currently in the market of building and finishing materials the most popular and High quality products with the following markings are common.:

- 31;

- 31C;

- 35;

- 45;

- 45 C;

- 75.

Let us examine each marking in detail:

- Penoplex 31. This is a type of material that has not the highest strength characteristics. Such coatings are not recommended for use in areas where there is a heavy load. As a rule, such penoplex is addressed for the insulation of tanks and pipelines.

- 31 C. Materials that have such a label, also can not boast of sufficient strength. They are most often used for wall insulation inside the home. From the raw materials of class 3, such a penoplex has a higher level of flammability.

- 35. The heat-insulating material with such marking possesses quite good strength characteristics. In addition, it is characterized by excellent insulating qualities. With the use of such coatings they warm the foundations, floors and pipes that go underground.

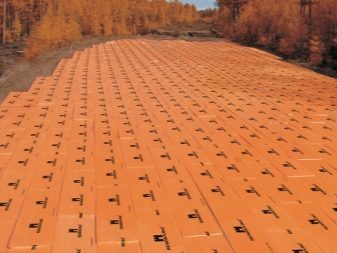

- 45. There is also a penoplex with marking 45. This kind of material is used for warming runways, and pavement. Moreover, such insulation is ideal for flooring in the conditions of production space and other similar premises.

- 45 C. The material with this marking has almost the same parameters that I penoplex 45. It is quite reliable and durable. However, such insulation is more often used for wall decoration in industrial areas.

- 75. Such marking belongs to special materials that have a density of 40-53 kg / m 3. Such raw materials are most often used in the construction of runways located at aerodromes.

Penoplex belonging to the class "standard" with a density of 25-31 kg / m3 has the following technical characteristics:

- width - 600;

- length - 1200;

- thickness - 20, 30, 40, 50, 60, 80, 100.

Material type "comfort" (28-33 kg / m3) has the following dimensional parameters:

- width - 600;

- length - 1200;

- thickness - 20, 30, 40, 50, 60, 80, 100.

The material for the foundation with a density of 29-33 kg / m3 has similar dimensions. As for the insulation "45" (35-47 kg / m3), its data are as follows:

- width - 600;

- length - 2400;

- thickness - 40, 50, 60, 80, 100.

These parameters are approximate. In the first place, the dimensions of extruded polystyrene depend on the manufacturer, who released them to the market.

Now in the shops you can find non-standard canvases.

Types and properties

Penoplex is a popular and popular material. It is represented by a variety of modifications, each of which has its own marking and designation. Currently, there are several varieties of this thermal insulation coating.

"Wall"

The density of such extruded polystyrene can range from 25 to 32 kg / m3. This heat-insulating material perfectly is suitable for installation on external and internal overlappings. In addition, the foam "wall" can be used in the design of partitions and plinth bases. Thanks to this material, the soundproofing characteristics of the room are improved.

"Foundation"

Such material as penoplex "foundation" is not less popular today. Its density varies from 29 to 33 kg / m3. This coating can be safely addressed if you want to warm the foundation and the upper part of the basement.This material has a high density and water resistance. In addition, this insulation is often used for thermal insulation of septic tanks with significant recess.

"Roof"

Another common and popular material is penoplex "roof". Such products are made directly for thermal insulation of roof or flat types of roofs. Also, the material from the category of "roof" is permissible to use for the insulation of attic structures. The density of this brand, as a rule, ranges from 28 to 33 kg / m3. This material is light and does not give a large load on the roofing sheath.

"Comfort"

Great demand today enjoys products "comfort". Such materials have a density of 25-35 kg / m3. They are used for the purpose of wall insulation in apartments. For example, it may be the territory of a balcony or loggia. Acceptable use of such coverage in the conditions of baths and saunas.

"Geo"

Penoplex "geo" is an alternative to materials belonging to the class "foundation". Such coatings are more often used in civil and industrial construction works. It should be noted that plates of this heater are often used for lining floors, foundations and other similar

"The foundation"

Penoplex from this category has the optimum density, allowing it to be used in a variety of construction works. This insulation is laid on the floor, walls and roofing foundation. Penoplex "base" is popular because of its durability and versatility of application - it is often addressed in both civil and industrial construction.

"Pitched roof"

Specially designed for roof insulation was developed penoplex "pitched roof". This coating is ideal for laying on the foundations of low-rise buildings. As a rule, this insulating material has a thickness of 10 and 15 cm.

"Facade"

The name of this type of penoplex speaks for itself. It is used for warming plinths, facades, exterior parts of floors and partitions. On this material there is a special milled surface, on which plaster is much easier and safer. The thickness of the foam facade "is" 20-100 mm.

Scope of application

Penoplex is recognized as one of the most popular and high-tech materials, therefore it is addressed in many cases:

- Such insulating material is used for insulation of walls, roof bases and floors.

- Many buyers choose penoplex to warm the foundation.

- There are materials that are used in road construction and the construction of runways.

- Some types of insulation installed in balconies, loggias, baths and saunas.

- This insulation is perfect for warming basements and basements.

- This insulation is used for both exterior and interior cladding of the house.

- Penoplex is used in the construction of not only private, but also industrial buildings.

As mentioned earlier, penoplex is good because it is permissible to use it not only in the construction of new buildings, but also in the restoration of old ones.

The main thing is to choose a material of a suitable class and type.

What can be replaced?

There are cases when penoplex for some reason is not in stores. Slightly less often, consumers themselves refuse to purchase this material because of the high cost or flammability. Many wonder what can replace this heater in such situations.

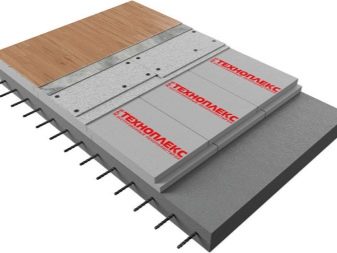

A good alternative to penoplex is a domestic material called Technoplex. This heater today is in great demand and is a strong competitor brandPenoplex brand products. It is good because it seamlessly falls on the base of a variety of materials. In addition, it can be safely laid on the floor, since it is permissible to combine it with the "warm floor" system.

Currently, Technoplex is manufactured using a special nanotechnology. It uses graphite, which significantly reduces the thermal conductivity of the insulation, but at the same time increases the rigidity and wear resistance of the plates.

This material has a silver-gray color that distinguishes it from penoplex. However, Technoplex has the same positive qualities as extruded polystyrene. That is why these materials are interchangeable.

"Technoplex" is made in a tiled format. Such insulating materials may have the following thickness:

- 100 mm;

- 50 mm;

- 40 mm;

- 30 mm;

- 20 mm.

In this case, the plates of such insulation are produced with grooves and spikes, with which they can be easily and quickly assembled, forming a neat seamless coating. Due to the absence of gaps on such a warming layer, “cold bridges” do not appear on the bases.

After the installation is completed, a material such as Technoplex must be closed with decorative finishing materials.

This requirement is explained by the fact that aggressive ultraviolet rays can adversely affect the quality and integrity of the insulation, so it must be “hidden” behind other coatings.

Another popular analogue of penoplex is Polyspen. This insulation is also produced in Russia. Currently available in three variations.having various technical characteristics, which include the coefficient of thermal conductivity, strength, and the level of flammability and compression:

- "Polyspen 45";

- "Polyspen 35";

- "Polyspen universal."

A flame retardant is present in the composition of such an analog of penoplex. Thanks to this component, "Polyspen" is less combustible. Such materials are available in the form of plates with a thickness of 20, 30, 40, 50, 60, 80, 200 mm. Thanks to this choice, it will be possible to choose a heater for a specific site.

Also penoplex can be replaced with the following insulation materials:

- "Stirex". Such material is rather strong and durable. The level of its thermal conductivity is slightly lower than that of penoplex.

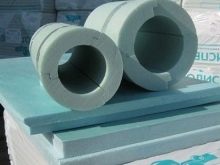

- Extrol. This is another polystyrene insulation that passes through extrusion in the manufacturing process.It has much in common with penoplex, but it is produced in the form of cylindrical elements, convenient for warming water systems.

- Styrofoam. Polyfoam (without extrusion) is often used instead of polyfoam. It is much cheaper than extruded polystyrene, however, it is less durable and durable.

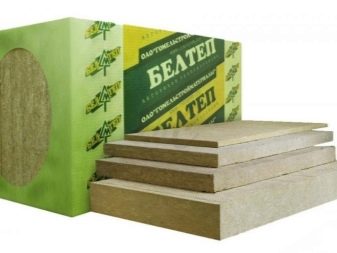

If speech insulation will be subjected to a constant presence in high temperature conditions, it is better to give preference to mineral wool. This type of insulation material today is one of the most popular and sought after.

By her own mineral wool - it is a fibrous insulation of inorganic origin. This insulation has many positive qualities, for example:

- quite high thermal insulation performance;

- water tightness;

- resistance to aggressive chemicals;

- good air exchange;

- excellent sound insulation performance;

- resistance to fire;

- long service life (25-50 years);

- environmental friendliness.

If you decide to use mineral wool instead of penoplex, then you should be aware of its weaknesses:

- this material loses its qualities if it gets wet;

- Minvata has a high level of dusting.

It is recommended to work with mineral wool in protective clothing and glasses.

Mounting technology

Laying penoplex on a particular basis can be made by hand. You do not need to have rich experience and cunning knowledge. The main thing is to stick to simple technology and use high-quality materials.

It was previously mentioned that the installation of extruded polystyrene foam can be done both inside and outside the home.

Consider in stages how to install this material in all these cases.

Inside the building

Penoplex is permissible to install in the inner part of the house. All work is done as follows:

- First you need to carefully prepare the base for laying insulation. In this case, you need to remove the old materials from the walls (any wallpaper, paintwork and others), while not losing a single section.

- Next, the base must be protected from mold and mildew. If they have already appeared, then you should get rid of them. For this, it is recommended to use special antiseptic compositions. After that, it is worth to sanitize.To do this, you can use almost any means with antibacterial action.

- Pay attention to the evenness of the grounds. Thus, the walls should not have significant differences and potholes. You need to get rid of any defects - level the bases, and then prime them with a qualitative composition.

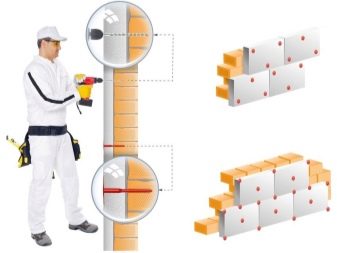

- Then you can proceed to the assembly basement profile. Such structures are most often addressed to facilitate the installation of insulation. In addition, the profile parts will protect the insulating coating from adverse external factors.

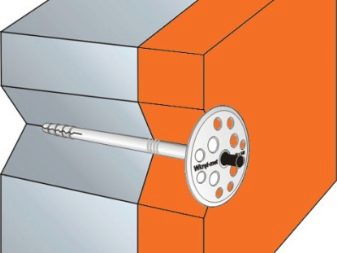

- The basement profile should be attached to the base on the dowel-nails. To insulate more closely to the ceiling, they can be supplemented with sealing washers.

- Be sure to follow the compliance of the width of the profile to the thickness of the foam.

- With the use of connecting plates, the final components of the structure must be docked with each other. Do not forget to leave between them a small gap (about 2 cm).

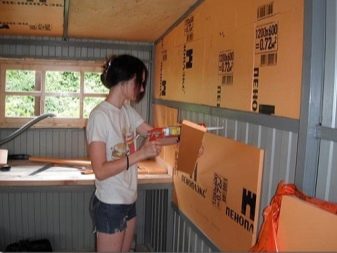

- Now it is possible to fix foam polystyrene plates. Apply a layer of glue to the penoplex (around the perimeter of the plate and in its center).

- Many masters recommend not to save at this stage and thoroughly fluff the whole polystyrene foam plate with a sticky solution. After that, the insulation must be pressed to the profile.If protruding particles of glue have appeared on the materials, they should be removed immediately.

- If there are small gaps between the materials, you can get rid of them by filling them with foam polystyrene inserts. In this situation, the installation foam is not used by everyone, since such sealing can cause cracking.

- After that, it will be necessary to finalize the thermal material on the base. When the glue is completely dry (as a rule, it takes about 3 days), work can continue. Fungi plugs need to fix the insulation. Hardware must be placed in the middle of the plates, as well as along their perimeter. However, here it is necessary to count on all the sheets of the penoplex to merge.

It should be borne in mind that the insulation of the home from the inside is not always appropriate and expedient.

The main disadvantage of this work is the reduction of residential and free space due to the thickness of the materials, as well as the profile design.

Outside

According to experts, outdoor insulation at home is more practical and convenient. At the same time, the free area is not concealed, and inside the rooms there is no accumulation of dirt and dust remaining during work.

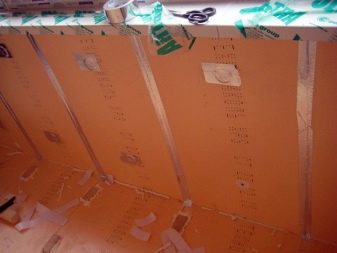

For outdoor insulation most often use penoplex, having a thickness of 80-100 mm.The installation process of heat-insulating material in this case is in many respects similar to the internal insulation.

To begin with, the facade of the house needs to be leveled. If there are cracks or gouges on it, then it is necessary to get rid of them - to seal them up, and then prime them.

Penoplex is glued to the facade base in the same way as with internal insulation of the dwelling. Similarly, fasteners on the dowels also occur.

If you want to continue to plaster the facade, then as a preparatory work you need to glue a reinforced mesh. If you want to trim the house with siding or PVC panels, then you need to take care of the vertical guides in advance in order to secure them. In this case, an additional layer of vapor-insulating material is not needed.

On the roof

Penoplex is ideal for strengthening the roof. This heater is addressed not only beginners, but also experienced craftsmen.

- Insulation plates can be laid only after the frame construction of the roof has been prepared (batten). In the lower section of the rafters near the warming zone you need to nail the bar. Its thickness should be the same as the thickness of the insulation.This item will play the role of the starting rail. This element must be set at an equal distance from the edge (on all truss supports).

- Starting from the starting rail, you need to lay the plates of extruded polystyrene. This should be done in a checkerboard pattern. The thickness of the laid layer, first of all, depends on the geographical location of the object under construction. However, experts always recommend laying insulation not in 1, but in 2-3 layers. At the same time it is very important to block all the joints qualitatively.

- In this case, the insulation can be fixed with the help of screws with hats, fungi, so that the design was more reliable. Stitches should be further glue. After that, the bars are packed over the insulation. They should be located from the top down. Thus you get a high-quality ventilated gap. It is necessary for the free circulation of air.

- After that, it is necessary to install a crate intended for directly mounting the roofing material. For this purpose, the construction assembled from bars fixed in compliance with a certain step is quite suitable.

- You can also use solid coatings made from OSB. Such bases are ideal for installing soft types of roofing. On the ridge, the insulating material should be secured closely.

The gap should be left only when installing the roof itself.

Insulation Reviews

Today, many homeowners opt for penoplex. Let's look at the list of positive qualities that satisfied customers noticed:

- According to the house masters, the installation of the penoplex seemed to them rather simple and fast - many did this work on their own;

- pleased the customers and the small weight of this heater;

- Penoplex is not afraid of temperature fluctuations and moisture, so many buyers have installed this heater in baths and home pools;

- could not please the homeowners and the insulating characteristics of this material;

- The lion's share of consumers noted the durability of Penoplex - it does not have to be constantly repaired or replaced in the first 2-3 years after installation.

Of course, people found in this insulating material and what did not suit them. Consider what the disadvantages of penoplex modern homeowners note:

- The main drawback noticed by the buyers is the flammability of the penoplex, due to which the owners of the houses do not consider it safe;

- Some buyers noticed that insects are infested in Penoplex (in this case, everything depends on the manufacturer’s good faith, since these problems should not arise with high-quality material);

- many consumers are not satisfied with the cost of penoplex, despite the fact that it belongs to the average price category;

- homeowners also noticed that penoplex was easily pressed during installation, but no one took this nuance to a serious shortcoming.

It is worth noting that most of the reviews on Penoplex are positive. Many buyers did not find for themselves a single drawback of this heater. Many problems can be avoided if you purchase quality material from a trusted manufacturer.

Such products will not disappoint you.

Useful tips

- Using penoplex, you should rely on the manufacturer's recommendations regarding the choice of insulation thickness depending on the temperature in your area of residence.So, in the central regions of Russia, it will be quite enough to install extruded polystyrene foam with a thickness of 30-50 mm in order to warm the foundation, and in the northern regions - a material with a thickness of at least 80-100 mm.

- Before laying penoplex be sure to prepare any base. Do not neglect this stage of installation work, otherwise the insulation will not hold tightly and reliably on the bases.

- Penoplex is not capable of harming substances such as alcohols, alkalis, any acids, water, ammonia, propane, butane or freon. This insulation is made taking into account the high biostability, which makes it more durable and reliable.

- For interior insulation, it is recommended to use penoplex, the thickness of which is at least 20 mm.

- Note that one of the most common mistakes of home craftsmen is the wrong selection of adhesive mixtures that are not suitable for the purchased insulation.

If you do not know what kind of glue is better to buy, then you should seek help from sales assistants - they will help you choose the right product.

- If you decide to warm the foam in the house, then you should use the installation method using lags.

- Before buying penoplex be sure to pay attention to its labeling. This way you will save yourself from buying inappropriate material.

- Note that the insulation of the dwelling penoplex should be carried out exclusively by special technology. Otherwise, the insulation will not last long and will be of little use to him. If you are afraid to take on such work, then it is better to entrust it to professionals.

You will learn more about Penoplex from the following video.