How to install a PVC window sill?

Current trends require innovations in every area of life, including repairs. With the development of technology, new materials and products are emerging, which differ much better. If earlier it was necessary to install two window frames to provide heat and sound insulation, now it is enough to install a thin plastic window that does an excellent job with the same functions and is also more efficient. Instead of heavy concrete windowsill, PVC products are now used, which are important to be able to correctly install in order to achieve optimum performance in operation.

Special features

Installing a plastic window sill in an apartment or house can be done for various reasons. The simplest of them is the wear of the old window and its complete replacement, including all its component parts. For a long time, metal-plastic windows have gained prestige and are very popular, as they are easy to install, and the service life and operating characteristics are very high.

Due to the fact that the modern window is a versatile product, you can choose from it a variety of window sills that will meet the stylistic task of the room and provide comfort.

The most versatile option is considered to be a PVC window sill, which ideally combines with the window itself, creating a single composition. In addition, the cost of such a product is much lower than that of more sophisticated versions of the type of natural stone. In order to accurately determine which window sill is best to put in the room, you need to know the advantages and disadvantages of this window element.

Among the positive qualities include:

- resistance to moisture and different temperatures - PVC window sill does not change the shape and appearance;

- no need for serious care of the product;

- lightweight sill, in contrast to similar options;

- does not need staining to refresh the appearance;

- does not shrink like wooden products;

- the ability to install this element of any dimensions, shapes and even colors, depending on the wishes of the owners.

If we talk about the negative side, then they should include:

- Hpupkost products - with careless operation on the windowsill may appear dents and even holes.

- If the top layer has a gloss, it is prone to scratches, which will quickly worsen the appearance of the product.

- Low resistance to very high temperatures. You should not put hot pots and kettles on the windowsill of PVC, because it can deform the surface, permanently spoiling it.

There are quite a few options for materials from which to make a window sill, but most often choose those that look good and have the right characteristics. If we talk about PVC construction, an important advantage is that it is inexpensive, it does not need most of the additional work that is inherent in other materials: treatment from corrosion, rotting, painting.

In addition, due to the excellent characteristics of these window sills correspond to GOST, because they are not harmful to humans and have parameters that ensure the safety of residents.

Style and design

Since metal-plastic windows are often white, PVC window-sills were initially performed only in this version. With the growing popularity of this product, different colors of both windows and window sills began to appear. Most often, the white color variation is wood imitation, which is used in bedrooms or in the nurseries. In addition, this option allows you to install modern designs in a wooden house, which apparently will not stand out, fitting into the concept of the building.

For the production of this kind of products used laminated PVC film under the tree. To impart the desired properties, impregnation with melamine resin is additionally carried out.

Thus, it is possible to give the surface the appearance of any wood, be it oak, alder or cherry.

In addition, windowsills with a natural stone finish are also popular, most often it is granite or marble.Thanks to this solution, you can avoid buying expensive and heavy products, but you can get an equally beautiful window design. If you need to somehow decorate the room, which is especially often the case with a children's room, then you can resort to using color options for window sills.

They may have a different texture and shape, which are selected according to the wishes of the client.

If we talk about convenience, then for each type of houses there are options of different lengths and widths so that you can make the most of the space. Brick laying is different in width from the walls of the prefabricated house, and therefore the window sills here need different. If we talk about the original design solutions, then you can make a windowsill-countertop, which will perform two functions at once, thereby making it possible to do without buying a table.

This option will look good in small kitchens or bedrooms where you need to place a lot of functional areas in a small space.

Using a glossy or matte finish, the original shapes and sizes are all that the owner of the PVC window sill can get.Often these options are made to order and they cost a bit more expensive, but the appearance of the room with such an accessory will be inimitable. Each owner himself decides what to install in his home based on taste preferences and financial capabilities.

What to install?

Typically, window sills are made in standard sizes to fit the most common versions of windows. But since frames can often have atypical characteristics, it is very often necessary to cut the product in place so that it fits as well as possible under the window. To approach the process correctly, the first thing to do is to take all the necessary measurements, and only after that cut off the excess.

It is best to markup with a pencil or marker so that it can be clearly seen.

Necessary tools and accessories

Any repair process requires the correct selection of tools to ensure maximum efficiency of work, and the correct choice of components will make the process of operating the product simple and not causing any problems and concerns.

To install a PVC window sill, you need to have:

- directly product itself;

- corner to determine the slope of the window sill;

- level to check the flatness of the installation of the product;

- marker with tape measure for marking;

- silicone sealant for sealing joints and seams;

- polyurethane foam for eliminating cavities between the window sill and the wall of the house itself;

- jigsaw for cutting off unnecessary parts;

- punch to dismantle the old structure and provide the necessary conditions for a new one;

- screwdriver for fastening the window sill;

- screws with screws;

- cement mortar for leveling the surface under a new window sill and sealing the installation sites of the structure;

- a stationery knife and clean rags to make the window construction complete.

In addition to the basic tools and materials, you should not forget about the additional ones, which include slopes, thanks to which the window is transformed, creating a completely different perception of the room.

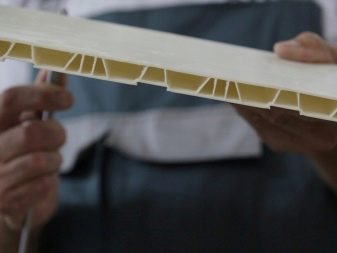

Overlay on the window sill, which is worn on both sides of the product, is necessary in order to beautifully frame it and close the cavityinto which dust or moisture may get, from where it will not be easy to remove it. Usually it has the form of a smooth strip with protrusions at the ends.

When installing it, you need to cut it in half, and then measure the required amount so that it ideally “sat down” on a new window sill.

In order to cut the window sill, you can use several tools:

- Hacksaw on the metal there in any owner of the house. The process of cutting it will be long and will require considerable physical strength.

- Jigsaw, which is best suited for such work, as it cuts off excess parts quickly and without much difficulty. For best results, it is important to set the motion of the pendulum to zero, and to work choose a metal file with small teeth.

- Bulgarian It helps to make trimming unnecessary parts very quickly and accurately, but at the same time it is very noisy and dusty in operation.

- Cordless Saws are wireless tools. It is easy and convenient to work with such equipment, but their disadvantage lies in the high cost of the tool.

When all the tools are ready, you can get to work, in which it is important to adhere to all the recommendations, otherwise the product may skew and the appearance of the window will suffer greatly.

It is important to remember that the places that need to be filled up should dry out for a while in order not to change their characteristics.

Preparatory work

In order to install a new PVC window sill, the first thing to do is to dismantle the old structure. Depending on the material from which it was made, and will be carried out certain work. It is best to clean the old parts carefully so as not to damage the masonry and do not have to restore it. If it was not possible to dismantle it efficiently, then additional procedures will be needed.

First of all, the surface where the window sill will be installed is cleaned of debris and unnecessary parts. Next, you need to calculate which dimensions the new window element has and whether it is necessary to resize the opening. If both designs had approximately equal indicators, then the process will proceed faster. If there is an obvious difference, then it is necessary to carry out work on adjusting the size of the window opening to install a new PVC product.

If the window sill is thinner than the former, the difference is eliminated with the help of cement mortar, if it is thicker, then the excess part can be removed with the help of a perforator, after which it is necessary to make a concrete screed.

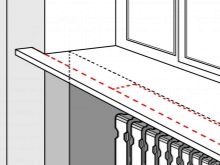

Calculating the height of the base for the installation of a new element, it is important to consider the gap for the foam, on which the product will be mounted. It must be at least 2 cm.If necessary, additional work is carried out on fitting the slots in the side slopes. In order for the window not to let in the cold, it is important to exclude any possibility for this, which is why the junction of the frame with the sill is coated with silicone sealant, after which the installation itself takes place.

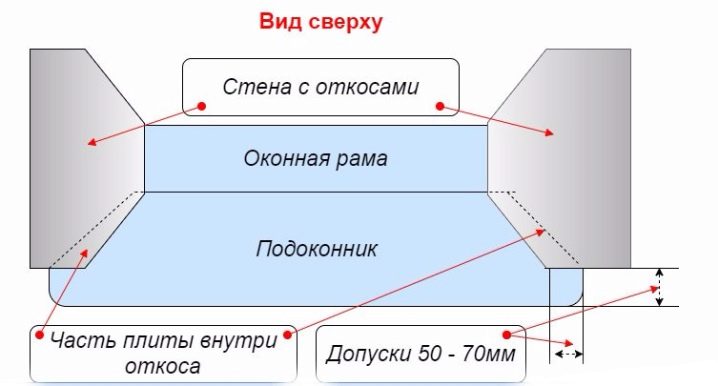

Calculating the width of the window sill, it is important to determine exactly where it will begin and end. You can make it a wide window or leave a margin of a few centimeters, so that the edges on each side go into the wall. Typically, such gaps are four to six centimeters long.

In the slopes, initially you need to make cuts, into which the new PVC window sill will be inserted.

Subtleties of installation

In order to install a new PVC window sill with your own hands, you need to correctly assemble the structure. The installation process of such parts can be carried out using:

- polyurethane foam and special glue, which are used to fasten the window sill;

- brackets for fixing;

- Profile for installing PVC products.

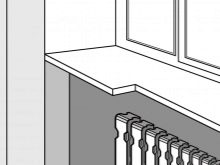

The most simple and convenient option for installation will be the option with foam. The first step is to prepare wooden wedges, which will serve as a support for the new window sill. They are placed over the entire surface of the prepared base.It is important to check the installation flatness using a level and note the slope of the product. It is necessary that the bevel be sent to the room in order to give direction to the condensate not to the stove but to the room.

If there are any inconsistencies in these indicators, the wooden wedges can be increased, or, conversely, reduced, depending on the situation.

All work is carried out in stages to avoid installation errors and unsatisfactory results. Once the wedges are properly sized, the free space between the sill and the base is covered with foam. To the angle of inclination has not changed, it is important to install on the window sill weighting, which will give the desired resistance, so the foam will harden correctly. For complete solidification, not less than two or even three days should pass, after which weighting can be removed and a window sill used.

The installation process of the window and the window sill goes step by step, and it is important to consider all the steps in order to get a decent result at the end. This process is inextricably linked with the decoration of the walls, because planning an installation option, you need to think in advance how further work will be carried out.

- If you plan to put a window sill before sandwich panels or plasterboard are finished, then you do not need a tile at the bottom. Increasing the thickness, the plate will be pressed with the help of finishing material.

- If the slopes will be lined with varnish or paint on putty, then in this case, it is necessary to churn the surface.

If you plan to use massive elements in the form of wood panels, clapboard, cork, Venetian plaster for the window, it is important to consider the protrusion of the plate, taking into account the thickness of the coating. Otherwise, it will be recessed inside the opening, which will not look aesthetically pleasing.

Thus, replacing the window requires that the old concrete window sill also be dismantled and replaced with a new one. For the convenience of further work, it is desirable to remove the old structure without any damage to the masonry.

It is possible to replace a heavy and outdated window-sill with the help of a modern PVC product, which is not only light and durable enough, but also has a diverse appearance that can be matched to the style of the room, which is very convenient.

The process of work is reduced to the following stages:

- Installing a new product, putting it in pre-prepared slots.

- Align the window sill relative to the window with wooden wedges.

- The fixing process, when the window sill can be fixed with the help of foam, which for many years will provide excellent performance characteristics.

- Use caps that may have different shapes. Depending on the design features of the window sill, they can be without ears, if the thickness of the product is quite large and there is a desire to make it look like a stone monolith, or with ears with a minimum thickness and a simple variant of the window element.

To change the window sill quickly and correctly, it is important to perform all the steps, which include dismantling old structures, installing new and finishing works. This is important, because improper disassembly of the old product will add unnecessary work, inaccuracies in the installation of the new will lead to problems in operation, and improper finishing work will affect the final appearance.

To remove the foam that remains after installation, you must first cut it with a stationery knife, and then apply a layer of tile glue,which after drying you need to putty. Only after that the surface can be painted or pasted over.

Dimensions

To make a quality repair, you need to choose the right materials for it. When replacing windows and a window sill, it is worth choosing the size of the latter correctly. The standard width for it will be the dimensions:

- 50-60 cm, if the installation will be carried out in a brick house;

- 20-25 cm for panel houses.

The widest sill, which can be found on the open market is the parameter 80 cm, and the narrowest - 20 cm. If we talk about length indicators, it can be from 1.5 meters to 6.

All unnecessary parts are cleaned during installation so that the resulting window has an aesthetic look.

If we talk about atypical windows, for example, small structures in a bathroom or other room, then there is no need to use a large sill, the best solution would be a width of 10 cm. Almost all standard products are 2 cm thick, which is sufficient for moderate loads and full use of the window element. There are thinner products, where the thickness is 1.8 cm, which implies lightweight loads on the surface.

If the window sill is planned to be used as a table, then its width should be sufficient for this, therefore products of width from 60 cm to one meter are produced. You can use this option in almost any room where you need to minimize the amount of furniture and increase functionality.

Colors

Due to the emergence of new materials for the manufacture of window sills and color options for such products. The simplest of them is the use of various colors and shades, which can be either transmitted to the window itself or used separately as a decorative element of the room.

Often these accents are made in the kitchen, bedroom, nursery, where there is an opportunity to add color to the interior.

For a more sophisticated appearance, you can use window sills with imitation of natural stone, marbled and granite, or wood, which looks especially beautiful in wooden buildings. A variety of options for window sills can include not only color, but also texture, which is glossy and matte.

For the original style and giving the interior an expensive look, it is better to use gloss, and in a quieter room a matt version will look great.

Tips

Window repair is always accompanied by nuances that are desirable to know and skillfully use.

- If you need to use a puncher, it is important to protect your face and hands with glasses and gloves so that nothing gets on them.

- When working on a base for a new PVC product, you need to clearly know its dimensions so as not to beat up the excess part of the wall, but also not to make the hole smaller than necessary.

- The gap that forms between the sill and the surface on which it lies should be sealed with foam. To make this material better, it is important to wet the surface before use.

- Choosing the width of the product, it is important to know that its protrusion beyond the slope should not exceed 6 centimeters. If this is neglected, then the circulation of air masses can be disturbed and the windows will mistreat strongly.

- Repairing a balcony and replacing windows with access to it, the thickness of a standard window sill will be 20 cm, but with suitable dimensions, even meter-long products can be used. You can also fix the product on the balcony with foam or glue, depending on the situation.

Useful tips on choosing and installing windowsill and slopes, see the following video.

Successful examples and options

- Windows can be installed both in a wooden house and in a brick one, and depending on this, you can choose the color of the whole structure and the design features of certain parts.

- The use of a wooden window sill in combination with the frame in the same color harmonizes with the whole house, which is decorated with modern materials with imitation of wood.

- For the children's room, you can use unusual versions of the window sill, where not only different colors are used, but also imitation of stone is present, which creates a unique color of the room.

- Window sills with imitation of natural stone look beautiful and stylish. They can be used in a variety of areas, in each of which it will look organically.