Fireplace device: types and principle of operation

Currently, fireplaces are becoming increasingly popular. Classic options are installed, as a rule, only as a decorative element or an additional source of heating. The fact is that the device does not provide for the accumulation of heat, the room is rapidly cooled after the flame goes out.

The classic design serves as an additional source of room ventilation, which is not a plus in the harsh Russian climate. To avoid negative factors and create an atmosphere of soulfulness, the developers have found affordable ways to preserve the beautiful tradition of heating a private house.

Features and types of design

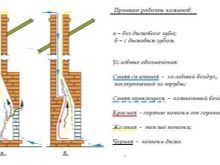

Fireplace wood and coal - one of the most common options in country houses. It is built from all sorts of materials - brick, concrete, sheet steel or other metal. A distinctive feature of all classical species is a straight chimney connected to the wide open space of the firebox.

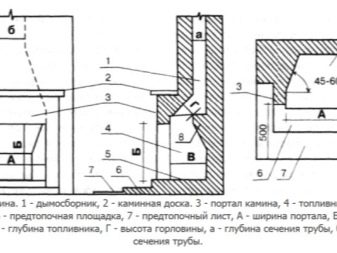

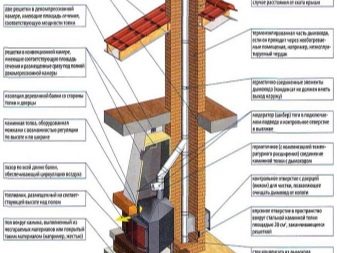

Consider the main elements of the fireplace.

- Sub - lower strictly horizontal part of the structure, designed for the location of firewood. May be deaf or with grate - holes.

- A firener is a space for fire. The rear wall to increase the reflection of heat in the room have a slope. In some classic versions, side walls are also laid out.

- The smoke chamber connects the firebox and the chimney; it is necessary for the collection of gases during the strong formation of smoke.

- A smoke tooth or a gas threshold is a protrusion in the chamber that prevents the occurrence of reverse flow and ensures the collection of condensate during firing. The width of the element coincides with the same size of the camera.

- Pipe or chimney - serves to divert smoke. It can be square, round or rectangular.To adjust the length of the design set one or two valves. They also prevent natural ventilation when the fireplace is idle.

- The portal is the entrance frame of the firebox, serves as a restriction of the working area and a decorative element at the same time.

Forms of the portal may be different depending on the style of design. U-shaped inherent in the English, Old German, French styles, as well as minimalism and high-tech. To form "D" country and modern modernity. Metal allows you to create any configuration from a classic barrel to an intricate bird's nest or pear.

As a finish, lining is applied with natural stone, expensive woods, brick, refractory plaster or tile. Fine in expensive models of portals looks forging or inlay.

Choosing a fireplace for the house, you should look not only at the exterior design, but also at the place of its future location.

By type of construction are distinguished:

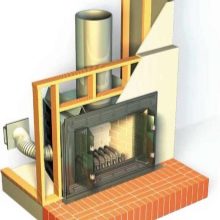

- built-in (closed) - arranged in recesses of walls or specially designed niches, the portal does not protrude beyond the line of the wall;

- half-open - partially protrude beyond the line of interior partitions;

- in the openings - angular options that can heat two rooms at once;

- wall - based on the name, do not have a fulcrum, are fixed on the wall or in the corner; as a rule, small in volume;

- open.

Heat exchange

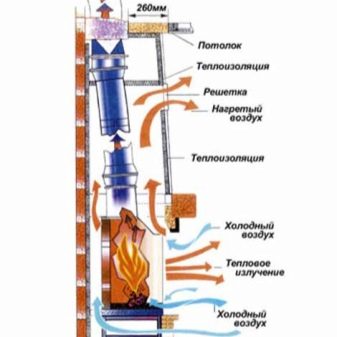

The principle of operation of the fireplace is simple. Heat is distributed in the room at the expense of radiation energy from fire and heating elements of the structure, which creates a slight movement of convection currents.

The impressive size of the chimney prevents the ingress of carbon dioxide into the room. A rather large, necessary speed of air movement in the pipe is not less than 0.25 m / s.

The heat output of a classic fireplace is small - 20%, the rest goes through the chimney.

It is possible to increase the intensity of heat release in several ways:

- additional installation of the side and rear walls of the structure;

- using metal as a covering for the firebox walls;

- equipment portal fireproof door, which completely covers the firebox (for metal products).

On sale you can find a large variety of ready-made fire-resistant steel furnaces.Professionals recommend to give preference to models of cast iron: they are insured against deformation at high temperatures. But the main guideline for finished products is the compliance of the characteristics of the model indicated in the data sheet to the conditions of your premises.

Doors for metal fireboxes can be of various sizes and ways of opening: upwards, to one side. Restricting the flow of air in enclosed structures provides not the burning, but the smoldering of wood. The walls of the fireplace are heated and supply the room with heat. In such conditions, one bookmark of firewood is enough for the whole night.

Restricting an open flame zone also affects the heating intensity.

- two walls of the portal on the sides - the power is only enough for small rooms; to increase radiation, the side inner walls are shaped as a trapezoid with an extension toward the room.

- one side panel - such forms contribute to the increased pulling of air from the room into the pipe, but the radiation of heat spreads to a larger radius;

- the flames are open on all sides (alpine or Swiss fireplaces) - inefficient for heating, although heat can be radiated in all directions.

Manufacturers of combustible biomaterials and pellets have also achieved a slowdown in the combustion process due to the characteristics of the composition of the feedstock. They claim that their products increase the heating efficiency to the level of a Dutch woman or a Swedish oven.

It is possible to increase the heat exchange by increasing the chimney area: its surface is heated and can also serve as a source of heat. For this, a heat exchanger is used - a ribbed insert in a stainless steel chimney. Its length is in the range from 0.5 to 1 m. The cross section of such a pipe should coincide with the diameter of the chimney.

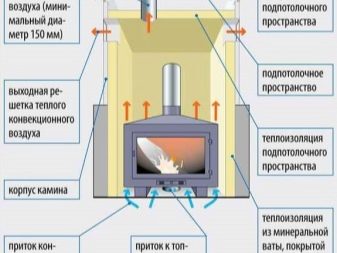

Forced air exchange

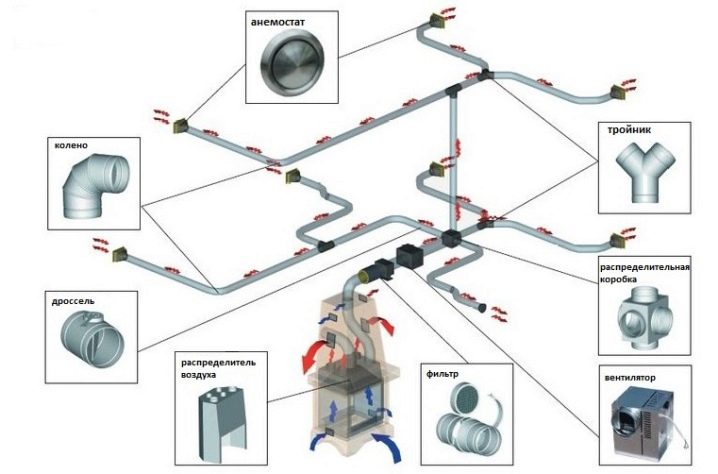

Knowledge of the air movement in the system will help to use the streams to increase traction and additional heating of a private house. And also make the management of the intensity of the heat supply automatic.

Natural air exchange is used, as a rule, when the fireplace is drowned occasionally. Artificial more efficient with frequent operation of the hearth or when the chimney system has a complex configuration. No matter how they reduce the number and length of the horizontal elements of the pipe, they manage to play their negative role.

The essence of the improvement is that the inflow of external air increases the draft, and ensures its constant value. It also removes air traps that form when there is a large temperature difference inside and outside the building. With kindling at the onset of cold weather in such a system there are no problems.

To achieve this goal, one or two or three fans are installed. They are built in at the air inlet into the furnace and on the path of flow in the main channel away from the rooms where people live. The best place is at the level of the attic or utility room. The gravitational system does not overlap, and the amount of air entering the system increases immediately by 30-50%, the throughput capacity - up to 600 m3 / h.

It is possible to automate the system with connection to the temperature sensor in the fireplace. To manage the control panel becomes possible without rising from the couch.

Equipment requires special - high-temperature centrifugal fans. Characteristics are selected based on the amount of air they can deliver and the pressure they exert on the system. The latter figure is determined by the pressure loss in certain sections of the pipe.

To equip needed:

- air distributors with protective grille;

- heat insulated air ducts of galvanized stainless steel, adapters;

- heat exchanger - air heating capacity is calculated with a margin on the folds;

- fans;

- coarse filters;

- throttle valves - needed to adjust the volume of incoming air.

In some cases, the air exchange system is equipped with a heater that is installed above the position of the heat exchanger. This allows you to quickly heat a large amount of incoming air and not reduce the degree of heat.

It is possible to automate the entire system with the connection to the temperature sensor in the fireplace. In such a case, it is easy to control a shield or a remote control without rising from the sofa.

Efficiency is enhanced if the pipes have an absolutely smooth inner surface and do not have a large number of horizontal and inclined joints. Ideal conditions are achieved with a round cross section of chimney parts.

With all the advantages of such a solution, there are also disadvantages:

- increased energy consumption — solid fuels and electricity;

- fan noise occurrence - special silencers are needed to suppress;

- noise in the pipes - occurs when the chimney is small in size, improper selection to the power of the furnace;

- noise and vibration indicate a marriage during installation, are eliminated repair.

Power

To determine the values there is a standard NF D 35376, which was developed in France. It allows you to find out the rated power of the furnace in kW - the amount of heat that the model is able to provide in three hours of work.

It is very important not to confuse it with the maximum values, which are usually indicated in the characteristics for finished products. The fireplace reaches its maximum heat within 45 minutes after kindling, and these power values are 2-3 times more than its actual capabilities.

Power is determined by the volume of the firebox: the larger its space, the stronger the nominal capacity. The sweep in the amount of energy ranges for fireplaces on average from 10 to 50 kW.

For reference:

- a comfortable room of 10 m² with a ceiling height of 2.5 m requires 1 kW for heating;

- birch firewood (dry, humidity up to 14%) - 1 kg gives 4 kW of energy when burned out.

Experts recommend choosing the power of metal structures by 10-15% more than indicated in the passport of the finished product, because the laboratory indicators, as a rule, do not coincide with the real ones under normal operating conditions.

The high power of the firebox allows, with the door closed, to heat the room faster and keep the temperature values in the smoldering mode longer. It is not advisable to use the limiting resource of the firebox for a long period of time, it will lead to its rapid wear.

The ability to supply the room with heat is provided not least by the dimensions of the model.

Dimensions

The scale of the object depends on the purpose of the installation. For exclusively decorative tasks, the values will be directly dependent on the values of other elements of the interior of a country house. Heating requires a different approach. It is necessary to calculate the power of the fireplace and connect it with the volume of the room.

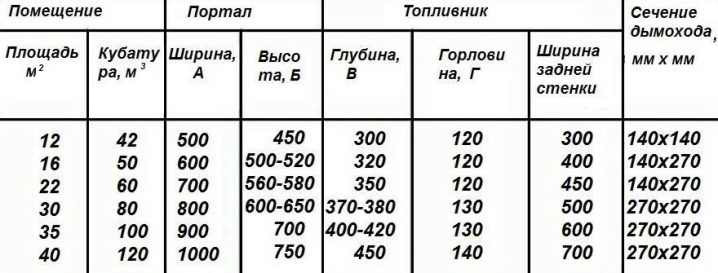

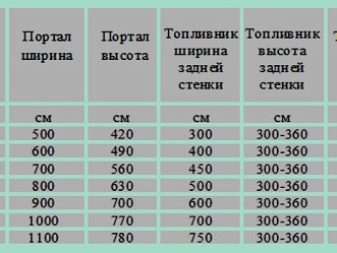

Table

Baseline values for a classic semi-open fireplace.

To comply with the harmonious combination of the main structural elements, it is necessary to consider the following factors:

- The height of the rectangular opening of the firebox is 2/3 in large fireplaces and 3/4 of its width in small fireplaces.

- The depth of the firebox should be in the range from 1/2 to 2/3 of the height of the opening of the portal.

- The area of the opening is always in accordance with the area of the room - from 1/45 to 1/65.

- The height of the pipe increases the thrust, it is much longer in terms of its values than for a conventional furnace. The minimum dimensions for a chimney flue from the base - a dry hearth or grate grate - should not be less than 5 m.

- The diameter of the chimney is 8 to 15 times smaller than the area of the room. The smaller the height of its construction, the larger the section for an equal area of the room.

For example:

- for a bedroom of 15 m² with a chimney length of 5 m, the cross section will be 250x250 mm;

- for a spacious living room of 70 m² with a pipe length of up to 10 m - 300x300 mm;

- for a living room of 70 m² with a pipe length of 5 m - 350x350 mm.

In addition to straight pipes, which are installed during the construction of the house, use inclined. They can be mounted to existing chimneys or ventilation wells, hoods. This option is suitable for installation under all necessary conditions in the residential premises of the cottage.

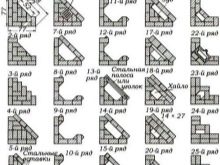

Fireplace do it yourself

The construction of such structures requires a lot of knowledge and skills. You can build a false-hearth on your own, it will hold onto slabs without any problems. For a real heated construction it is necessary to approach with all seriousness. Design must begin at the planning stage of the house.

Required steps:

- select a model and calculate its power;

- to carry out the calculation of the foundation and its combination with the floor overlap

- plan and display on the diagram the necessary changes in the design of the roof;

- determine the materials and their quantity for all types of work, including the lining of the fireplace;

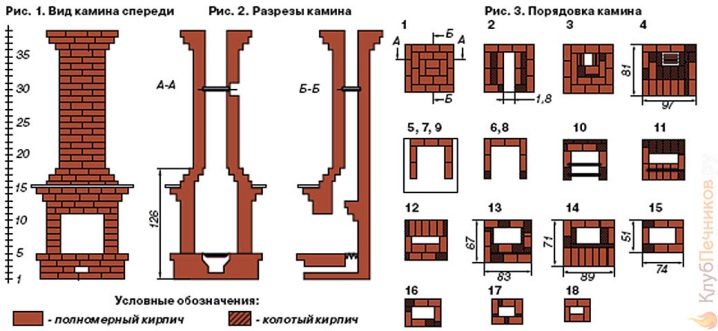

- create sketches and drawings;

- provide for the safety of use, pay special attention to fire prevention measures.

Before turning to experts for advice, you must present your future fireplace in all its glory. Begin with a sketch, and then proceed to a detailed study of the details of the future heater of the house.

The drawing is made in four angles: straight, side, top and sectional view. Skilled craftsmen make up detailed diagrams with each row of laying bricks and precise angles of cuts of elements.

Foundation

When it comes to working models of the fireplace, it is worth considering many factors.

- The foundation is erected separately from other load-bearing walls and crossbeams, since the loads on the elements are completely different, a pressure drop on the floor may occur, leading to the destruction of the building.

- The sole area must be larger than the base of the structure.

- The minimum deepening is at least 50 cm. The real value depends on the properties of the soil, as well as the measures for its compaction.

- The depth of the fireplace pit should be 20 cm below the soil freezing line.

- The free space between the ceiling of the building and the foundation is at least 5 mm. This will allow to avoid cracks, deformation of the structural elements and the design of the hearth when the temperature drops. The gap is usually filled with sand.

With today's extensive selection of finished products and materials for creating a fireplace with your own hands, it is easy to embody an old dream. Models can be selected for any wallet size.

To learn how to make a fireplace out of bricks, see the following video.