Smoking cabinets: devices for cold and hot smoking

Smoked products not only have a pleasant aroma and taste, but also have a long shelf life. In mass nutrition, natural smoking is most often replaced by a process of processing with liquid smoke. Smoking cabinets are devices for cold and hot smoking. They allow you to make smoked delicacies of fish or meat at home. You only need to purchase the right equipment or make it yourself.

Types of smoking

The design of the smoke cabinet will largely depend on the specific purpose of this equipment. The device may have different modes of operation depending on what temperature you need to maintain inside the cabinet.

The smoking procedure is of three different types.

- Hot. The smoke temperature in this case should be at least seventy degrees. The maximum value can reach one hundred and twenty degrees. This procedure can take from fifteen minutes to four hours, depending on the size of the products.

- Half hot. The temperature should be between sixty and seventy degrees. In this way, only very fresh semi-finished products can be processed.

- Cold Smoke temperature should not exceed fifty degrees. The minimum allowable temperature value is thirty degrees. This procedure takes a large amount of time, which can range from several hours to several days.

Specifications

Smoking equipment has differences in design and some characteristics. The device of the smoking cabinet depends entirely on what type of smoking it is intended for.

Instruments of all types must have three basic functions.

- Ensure uniform heating of food. The temperature and smoke in the cabinet must be evenly affected by the semifinished product.Otherwise, the taste of smoked meats will be spoiled.

- The smoke in the chamber should be light.

- The design should ensure the gradual penetration of smoke into products.

Cold

Low-temperature smoking equipment consists of the following main elements:

- combustion chamber;

- smoking cabinet;

- chimney.

For the manufacture of the furnace often use bricks or metal. The design of the chamber should allow easy cleaning of the ashes during the smoking process. Since the burning of firewood produces a rather acrid dark smoke, a smoke damper must be equipped in the firebox. It will send smoke to the chimney or take it out of the smoke box to the outside.

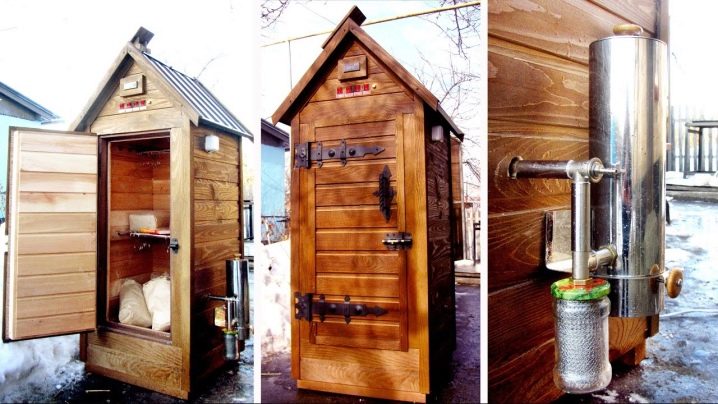

Since the process of cold smoking does not require high temperatures, the smoking cabinet can be made from the simplest materials, for example, from certain types of wood or stainless steel.

The only exceptions are materials with high porosity, since smoke and moisture will accumulate in the pores, which will lead to the formation of an unpleasant odor in the chamber.

The most convenient option would be a barrel of wood or metal. A hole is made at the bottom of the product to ensure the penetration of smoke into the chamber.To place the products in the smoke chamber inside the barrel, you must fasten metal bars or hang hooks. You can use moistened burlap as a cover.

A distinctive feature of the design of devices for cold smoking is a long chimney. For the manufacture of such a design is best suited metal. However, it should be remembered that the metal chimney requires regular cleaning from soot. You can dig up the chimney in the ground, then the soil will absorb the condensate containing carcinogens.

Hotter

Hot smoking takes place at fairly high temperatures. Such a temperature is achieved not by burning wood, but by burning special chips. Time smoking depends on the size of the product, but in any case, much shorter than the processing time with cold smoke. The combustion chamber in the hot working devices should be directly under the smoke chamber. The furnace can be built from a gas burner for boilers or electric hotplates.

The smoking chamber should be as airtight as possible, which will allow the smoke to be evenly applied to the semi-finished products.

The closing design of the smoke chamber can be equipped with a water seal. It is a small depression in accordance with the size of the chamber and the cover. In the resulting tank is poured water. Top construction closes the lid. This allows you to form a barrier that protects the camera from the penetration of air from the outside and does not release smoke from the inside.

Hooks or grills for products are placed inside the smoking chamber. Grill can be made independently or take a product for a barbecue. A mandatory element of the chamber for processing hot smoke is a container for flowing grease and dripping juice from semi-finished products. The pallet should be easily removed from the equipment, as it must be periodically cleaned of accumulated dirt.

Half hot

Devices for half-hot smoking have the simplest design. Most often, this kind of equipment is used for home processing of meat and fish products. It can be built from a gas stove with a hood or from a steel box. The wall thickness of the stainless steel box must be at least one and a half millimeters, black steel - three millimeters.

The smoke box should be equipped with a lid, a container for collecting fat and grills for products. Chips are poured on the bottom of the cabinet, after which the product is installed above the fire. The chips smolder under the influence of high temperatures, forming smoke in the chamber. A small hole can be drilled on the lid of the product so that a small amount of smoke during smoking goes outside.

How to make yourself?

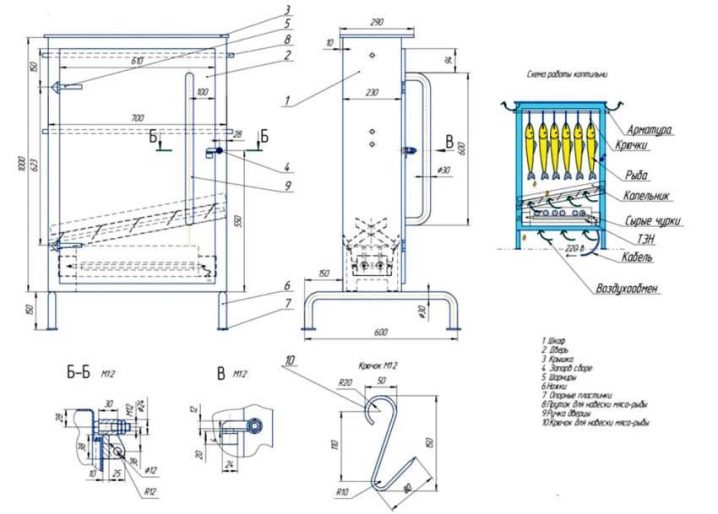

Making a smokehouse with your own hands for a particular method of processing meat and fish semi-finished products will not be particularly difficult. It is only important to know the method of operation of the device for a particular type of smoking. Ready-made instructions and equipment drawings can be easily found on the Internet.

The device for processing cold smoke is often made from a wooden or metal barrel. Devices made of wood are convenient because they can be insulated from the inside, unlike metal products. Insulation can be any material that does not emit toxic substances when heated: cellulose wool, mineral wool, felt. Designs for hot processing are best done in stainless steel.

As an example, consider the self-made construction of a low-temperature cabinet from a barrel of 100–200 liters. The upper part of the tank is completely cut off, and a hole is made in the lower part for connecting the chimney. It is possible to make a pan for collecting fat from the cut part of the barrel. For semi-finished products in the chamber, it is necessary to make a grid or hang the hooks on the bars of the reinforcement.

The lid of the chamber is best made from wood. From 5 to 10 holes are drilled in the product to release moisture. Instead of a wooden cover, you can use burlap. Before you begin to smoke, the material must be wetted in cold water and squeezed out carefully.

To learn how to make a smoking cabinet with your own hands, see the video below.