Powder paint on metal: characteristics and properties

It is possible to name the big list of products for which covering use special powder paint. This material has excellent protective properties. It is anticorrosive, resistant to mechanical stress, has a wide range of manufacturers. In addition, this paint is heat resistant.

If you need to update the appearance of the body, furniture or any metal product, it is better to choose this option of coverage.

Benefits

The modern market of finishing materials offers a wide range of products for dyeing products from different materials. If we are talking about a metal surface, better powder types you will not find.This can be explained by a number of advantages that these colors possess. Due to the characteristics of the composition can achieve a unique physico-chemical indicator.

You do not have to spend a large amount of paint, in most varieties it is economical, and at the same time it qualitatively paints the base with just one layer.

This coloring agent has an increased level of anti-corrosion and resistance to impact., which distinguishes it from other types of such material. This coating hardens in half an hour, other paint and varnish compounds cannot boast of this.

Main characteristics

After applying the powder paint does not remain waste. The polymer coating has a protective and decorative property, so the appearance remains presentable for a long time. This material is used for processing metal, glass, ceramics and several types of plastic. Means based on substances that allow the formation of a protective film on the surface against temperature changes and other external influences are in great demand. Initially, the range included acrylic, epoxy, and polyester powder formulations.Only then did the hybrid varieties appear.

Flowability is a must in such products. This indicator plays an important role. It is influenced by several characteristics, including the glass transition temperature, surface smoothness, chemical composition, and also moisture. When buying, it is important to pay attention to the shelf life of the product to make sure that you have found quality material. Returning to flowability, it should be noted: if it is low, the paint will be unevenly distributed.

The composition of the powder affects the bulk density. This includes the degree of polydispersity with the shape of the particles. In pigmented materials, this is usually high due to fillers. Products must have the ability to electrify.

It is better to pay attention to polyvinyl, epoxy, polyethylene powder paints. The charge will last longer, but if the humidity reaches 70%, this figure drops. Due to electrification, the physical properties of the material change, as evidenced by a decrease in flowability and bulk density. This should not be allowed if you want to extend the life of the coating.

Fluidization property

Experts pay special attention to this indicator. If the dyeing is carried out according to the “fluidized bed” technology, this characteristic is important during air blowing. Powders made from polypropylene, polyethylene or polyvinyl chloride have a low rate of fluidization. Fine dispersion materials may not be suitable for technology at all. During the work they use professional equipment.

How to choose?

Choosing powder paint, you must be guided by certain criteria, carefully study the technical characteristics of the material. A rich assortment will open up before you, you can seek help from qualified specialists who understand this area and can give useful recommendations. So the purchase will meet your expectations.

First of all, take into account the conditions where the surface to be painted is located. Since paints are chemically resistant, weatherproof, and for electrical insulation coatings, this moment plays an important role.

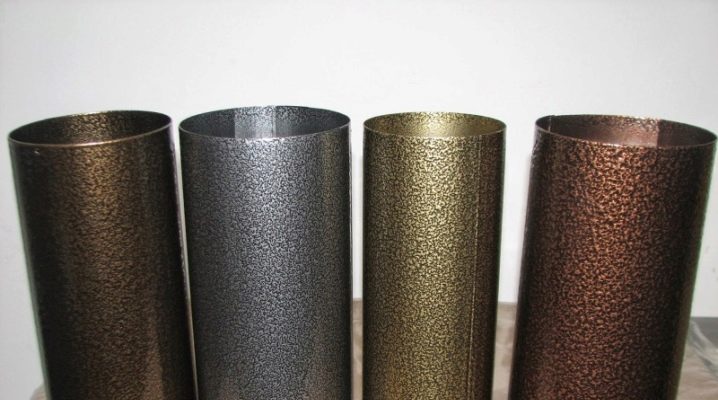

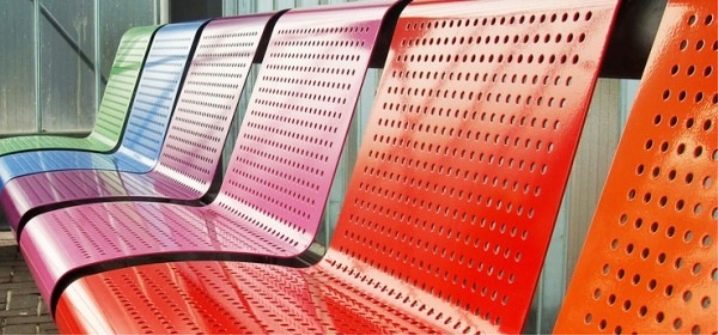

Products are subject to a certain classification, different colors, surface texture.The buyer always has the opportunity to choose between the glossy and matte varieties, variants of coating under the skin, marble, granite.

In the assortment of paint offered for sale are divided into two types: thermoplastic and thermosetting. The presence of film former is inherent in each type. Each of the varieties has its own characteristics, advantages, a method of forming a protective layer, they differ in performance characteristics.

Species

Available range is varied. Polyester formulations form a coating at a temperature of 170 degrees. It is necessary to apply them with a small layer, which is indicated in the instructions for use. They are distinguished by a mass of qualitative characteristics: they have a high resistance to chemical attack, chipping, they are solid, they do an excellent job with weather conditions.

This is one of the best materials that is suitable for covering the body of the vehicle, various metal products. Such a composition is often used for finishing horizontal bars, metal furniture structures, auto parts.

Polyester paints are prepared using carboxyl-containing polyesters, which form the basis.Surface painted with such a composition, resistant to bright light, resists corrosion. This type of paint is suitable for processing lawn devices, transformers, fences and even car tires. Some varieties are not resistant to chemicals.

Colorless finish

These include polyacrylate paints, which form a coating at temperatures above 180 degrees. They cope with chemical and atmospheric effects. Experts consider the characteristics of this material superior polyester-urethane. However, they cannot cope with mechanical stability. During dyeing, a smooth surface is obtained even with a small thickness.

The polyacrylate is created from resin blends, with the addition of glycidyl, it can quickly solidify. The coating is transparent, creates a clean surface, such staining is suitable for working with brass and chrome products. Epoxy paint has a protective function against corrosion, as well as electrical insulation. Such products are offered at an affordable price, suitable for working in an aggressive environment. The material has high heat resistance and adhesion, the surface is shock-resistant.

Hybrid

Hybrid formulations do not turn yellow after application, so they are better than previous ones. They can not be used in conditions where there is a direct exposure to sunlight. They resemble epoxy counterparts due to their mechanical properties and low resistance to chemicals. These tools are used for finishing shelves, office furniture made of metal, oil filters and various electrical tools.

Thermoplastic

The raw materials are polymers for which high temperatures are required. The coating has a slight adhesion, so the surface is important to pre-prepare. This requires fractional or sand blasting, and in some situations, priming.

Staining technology

Before work, you need to stock up on appropriate materials, prepare the surface, choose the option of coating. You should carefully examine this issue if you decide to do the work yourself, without the help of experts. If we are talking about applying material to the damaged part of the body, it is necessary to straighten it first. Then the metal is cleaned of rust, if any.

After that it is necessary to use a primer that will prepare the base for painting. Soil need to use one that is suitable for this type of surface.

After the primer is dry, you can apply the paint of the desired color. For some types of material put forward a separate requirement - heat resistance (if we are talking about products that are in appropriate conditions). Many manufacturers and specialists pack the product in cans. The use of such paints is suitable for processing surfaces with a small area.

If you decide to finish a large object, you must select an option in another form of release (for example, a can).

What else to consider?

To buy really what you need, you should consider a number of factors. An important role is played by the conditions in which painting will be carried out, the type of surface, the color of the coating. When choosing a material, it is necessary to take care that in the process of dyeing external factors (for example, cold) do not affect the durability and performance characteristics.

Selecting the material for the metal surface of furniture, you need to correlate the shade of the dye with the existing color design of the room: ineptly chosen color will interrupt the harmony of the situation.

When making a purchase in a store, it is worth choosing between several varieties. In order not to doubt the choice, you should first examine the information about each paint, scrolling reviews on building forums. This will allow you to become better acquainted with the quality indicators of the material. You should not take the first thing you like on the store counter: the art of selling is to put the material you need to sell in a good place.

The process of painting with powder paint can be viewed below.