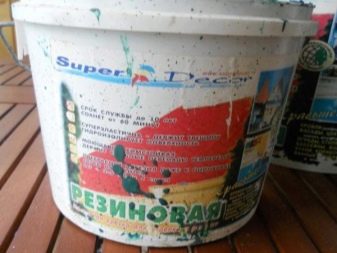

Rubber paint Super Decor: advantages and scope

Super Decor rubber paint is a popular finishing material and is in high demand in the construction market. The production of this product is carried out by the production company Rubber Paints of the Baltikolor company.

Features and benefits

A distinctive characteristic of rubber paints is the ability to form on the surface to be painted a durable and elastic coating with high flexibility and water resistance. Enamels are intended for coloring of the difficult bases having low indicators of porosity and differing in a smooth surface and poor absorbance. Hardly painted surfaces include laminate, plastic and metal. Previously, their high-quality paint required the application of special primer compounds that increase the adhesion of the substrate with enamel coating and the use of special paints and varnishes.

The appearance of rubber paints solved the problem of processing complex surfaces, and therefore quickly gained popularity.

The demand and high consumer demand for Super Decor rubber inks are due to the following material advantages:

- Flexibility and elasticity of the formed film prevents cracking and peeling. When painting wooden surfaces, wood becomes similar to plastic, and when wet, the paint layer stretches along with the wood. This provides reliable protection of wooden surfaces from moisture and prevents the appearance of fungus and mold. This property of rubber paint allows to paint easily deformed surfaces without the risk of peeling and exfoliation of the decorative layer;

- High wear resistance and durability of the emulsion make it possible to use the material under any conditions. The paint is well tolerated by direct exposure to ultraviolet rays and precipitation, it is thermally and frost-resistant and has high waterproofing properties. Paint is not afraid of sudden temperature shocks and retains its properties in the range from -50 to 60 degrees;

- Anti-slip effect allows the use of emulsion for painting floors and roofs;

- Noble appearance. The paint is compatible with any colors, which gives a wide scope for creativity and helps to realize the most daring design solutions;

- Ecological safety and hygiene of the emulsion allow its use in residential and public spaces without risk to human health. High water-repellent properties make it possible to regularly wash the surface, without fear of damaging the decorative layer. Despite the high moisture resistance, the paint passes air well and allows the surface to breathe. Due to the absence of solvents in the composition, enamel dries quickly and does not have a strong odor;

- Excellent adhesion performance provides excellent adhesion of the paint layer to metal, wood, plastic, slate and any other material. Throughout all term of operation paint does not exfoliate, does not crack and does not bubble.

- The incombustibility of the material increases the fire safety of the painted room;

- One liter of rubber paint is enough to paint five square meters of surface in two layers.

Technical specifications

Rubber paint SuperDecor appeared on the construction market relatively recently, but in a short time it managed to gain popularity and numerous positive reviews. It consists of water, acrylate latex, coalescent, antifreeze, preservative, and special additives in the form of color and color pigment. By its consistency, the paint resembles mastic. This is one of the few materials that can be painted galvanized iron.

The safety of the emulsion corresponds to the fourth class, which guarantees the complete absence of toxic and toxic components in the composition.

If necessary, the paint is diluted with water. The use of solvents is not recommended. The drying time of the painted surface ranges from 30 to 60 minutes and depends on the humidity of the air and the temperature conditions of the external environment. One liter contains 1.1 kg of enamel. Material consumption on painted and primed bases is 120-150 grams per square meter, on wallpaper, chipboard, gypsum board and fiberboard - 190 g, on concrete and plaster - 250 g. The paint is produced according to TU 2316-001-47570236-97 and has the necessary certificates of quality and compliance.

Application area

Rubber emulsions are universal and are used for all types of paint and varnish works. The paint is well applied and keeps for a long time on concrete, wallpaper, putty, brick, chipboard and fiberboard, wooden, asbestos-cement, asphalt surfaces and on galvanized iron. The material can be applied to surfaces previously painted with all types of paints: alkyd, acrylic, latex and oil. The emulsion can be used for marking on asphalt and treadmills, tennis courts, as well as be used for painting roofs, fences, gazebos, walls and floors. Thanks to good plasticity, it perfectly smoothes small cracks and seams, hides irregularities and gives the surface an attractive appearance.

Rubber paint is often used for dyes, dams and pipes., and excellent waterproofing properties allow emulsion to paint the bottom of the pool. It is not recommended to use Super Decor rubber enamel to paint doors and furniture.

Useful tips

In the process of working with rubber emulsion Super Decor, it is desirable to follow some recommendations:

- In the process of selecting the material should be considered the purpose of the emulsion.Many manufacturers produce products of a narrow focus, where specialized paint is provided for each surface. For example, the material for external work contains more frost-resistant additives, and the emulsion intended for concrete has an increased volume of acrylic latex;

- If the repair work is postponed for an indefinite time, then when buying should pay attention to the shelf life of the material. You should also read the accompanying documentation. This will help avoid the acquisition of a fake and will act as a guarantor of high quality goods;

- Before painting the surface of untreated wood is required to sand and process it with an antiseptic composition. Metal bases must be cleaned of dirt and degreased. It is advisable to prime the concrete walls, and wash the alkyd and oil surfaces with a solution of soda or sodium phosphate;

- It is necessary to produce staining in calm weather and at a relative humidity of not more than 80%. Direct sunlight during the work is also not recommended;

- To obtain a deeper color and increase the wear resistance of the coating, rubber paint is preferably applied in several thin layers. The time interval between staining should be at least two hours;

- The treatment of the freshly painted surface with antiseptic and detergent compositions can be performed no earlier than 7 days after completion of the work.

Beautiful examples

A wide variety of colors and a wide range of use of rubber emulsion allow for the realization of unique design developments.

With the help of this versatile material, you can decorate not only the interior, but also embody bold color solutions in the design of artistic images on the plot.

- The bathtub painted with Super Decor paint harmonizes with the color of the room.

- Anti-slip rubber coating - ideal for the floor.

- Paint for the roof will reliably protect the roof from destruction and decorate the facade.

- Rubber emulsion will make the pool stylish and tight.

For more on rubber paint, see the next video.