Hammer paint on metal: distinctive features and scope of use

Paint - one of the ways to protect the upper metal layer from destruction. However, not all such tools can withstand the harsh operating conditions of products. Therefore, manufacturers are trying to improve products by regularly introducing new modifications to the market. Particular attention should be paid to hammer inks that can easily withstand temperature changes and mechanical stress.

Special features

Hammer paint is a polymer mixture on a nitro-based. When the film hardens on the surface of the product, peculiar dents are formed on it. It creates the effect of hitting the hammer on the metal. This explains the name of the tool.

Manufacturers add a few more basic components to the solution:

- Metallic powder. In most cases, copper or aluminum is used in production.

- Glass fines. This component forms a texture on the surface after solidification.

- Aluminum flakes. They form a unique texture on the surface.

- Silicone or alkyd resins. They repel water well, not allowing it to leak under the protective film.

- Technical wax. After hardening, this component forms a protective layer.

Please note that a similar effect is observed when applying special powder paints. However, the cost of this process is quite high, since it requires the use of special equipment. Therefore, many people prefer hammer paints, which are easily applied under normal conditions.

Today hammer paints are widely used in construction.

This is due to the numerous advantages of such compounds:

- Resistance to temperature extremes and climatic stimuli. Almost all types of hammer inks easily tolerate temperatures up to +80 degrees.

- The mixture is universal, since it can cover not only metals, but also other materials.

- The paint is easy to apply without the use of specialized tools. For this, standard rollers or brushes are used. Some manufacturers produce compositions in the form of aerosol cans. Please note that some types of paint can be applied even if there is a strong wind outside.

- The period of drying the mixture does not exceed 2 hours. But the film gets absolute strength only after 24 hours after application.

- Products are environmentally friendly. When painting solutions do not emit caustic and harmful odors.

- The service life of the protective film can reach 8 years, which is difficult to achieve with the help of other compounds.

- Resistance to mechanical damage. This is due to the fact that the material is plastic even after drying. Peel off part of the film is quite difficult.

However, such paints may not always be the best solution.

This is due to several significant drawbacks:

- High price. The price of hammer paints exceeds the cost of similar materials (enamels) several times.

- The complexity of the application.To get a strong and durable coating, you should strictly follow the recommendations of experts during painting.

- The difficulty of removing. It is quite difficult to remove a layer of hammer paint. Therefore, it is recommended to carefully select the color if you plan to apply it with the top coat.

Where are they used?

Hammer paints have a unique technical characteristics.

Today they are used in various sectors of the economy:

- Industry. The composition is used for painting machines, structures and mechanisms. It is also the optimal choice as a protection for the enclosures of various electrical systems (switchboards, etc.).

- Automotive Hammer paint covers many types of disks, bodywork, as well as other metal parts of cars. This allows you to extend their life several times.

- Building sector. Here, using this tool to protect metal from corrosion.

- Painting forged fences to give them the effect of aging, as well as to prevent the likelihood of corrosion processes.

- Manufacture of metal furniture.In most cases, hammer mortars are used to paint entrance doors, safes and other similar products.

- Advertising industry. The compositions perfectly protect metal structures and are also used to create a decorative effect on various types of plastic or glass.

Kinds

Hammer paints have unique technical characteristics. At the same time, substances are constantly being improved, they acquire new improved properties. Today on the market there are several major brands of paint of this type.

- ML-165. Paint belongs to enamels, the main component of which is alkyd-styrene substances. Among the positive properties of the material can be distinguished heat resistance. Paint does not lose its original properties when directly exposed to temperatures no higher than 130 degrees. As a protective layer, the tool can be used for almost any type of surface.

- EP-1323 ME. Epoxy enamel that combines the properties of paint and primer mixtures. A unique product that is mainly used to coat metals that can be externally exposed (cranes, loaders, fences, etc.).Paint can be applied over rust, which eliminates the pre-treatment of the surface.

- NC 221. This paint has a low price. It is used as a decorative coating. The quality of protection is much worse here than the previously reviewed modifications. However, the composition well withstands external climatic conditions. It can also be used indoors.

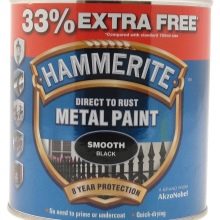

- Hammerite. This type of hammer paint is the most expensive and high quality. Suitable for coating various products. The tool can also be applied over rust.

Colors

The main task of hammer paint is the protection of metal surfaces. Initially, manufacturers did not pay attention to the color palette of the product, as they considered this moment as secondary.

However, today the paint is produced in different shades, among which there are such primary colors:

- the black;

- Gray;

- white;

- blue;

- blue;

- Violet.

Please note that many manufacturers produce formulations that can externally resemble the colors of wood, natural stone, etc.

However, the structure of such a paint is not always suitable for decorating surfaces.

Manufacturers

The modern market is saturated with hammer paints. The popularity of the product explains the appearance of numerous low-quality fakes.

Experts recommend to give preference only to well-known brands, among which there are several manufacturing companies:

- Hammerite. Some types of paints can be applied to galvanized metals only after they are primed with special solutions.

- Dali. The compositions are intended for application to metals (zinc, etc.), wood and plastic.

- Alpina.

The compositions of these grades are distinguished by high adhesion with metals, which allows them to be applied even over rust. According to reviews, paints resist moisture well, as well as the direct effects of oils. Some species are able to withstand exposure to the surface of weak alkalis and acids.

Another good option is the paint in cans from the company Kudo.

Users note that it can be easily applied in almost any hard-to-reach place.

How to choose?

A variety of hammer inks often leads to doubts when buying a product. To choose the right solution should pay attention to several factors.

- Method of application. The most popular are liquid solutions. For their application use rollers or brushes. Some manufacturers produce formulations in cans. Their price is slightly higher than the cost of a standard modification product. Usually they are used when you need to get a uniform layer of paint, as well as, if you want to fill in hard-to-reach places.

- Purpose Hammer paints are used as protective products. However, many of them require pre-cleaning of metal or other material in order to increase adhesion. There are also special modifications that are easily applied to rust. These products combine a primer and ordinary enamel. It is also important to pay attention to the substances for which the composition is intended. Hammer paints always work with metals, but they can not always cling to wood, glass or plastic.

- Physical and chemical characteristics. These parameters allow you to choose a composition that can withstand not only high temperatures, but also a relatively aggressive environment.

How to apply

The technology of applying hammer paint consists of several successive steps.

- Surface preparation. Before applying the solution, you should thoroughly clean the metal from greasy stains, as well as remove the exfoliating layers of the previous coating. New metal structures should be pre-treated with sandpaper or a sander. Minor damage will increase the adhesion of the solution and base.

Please note that all products made from non-ferrous metals must be primed with special solutions before painting.

If it is aluminum, then it is also desirable to clean it from the upper protective film, which is formed during the oxidation of the metal.

- Painting. This process can be carried out in various ways. The easiest option is to use a brush. The algorithm for applying hammer paint with this tool is no different from ordinary painting. Experts recommend using a brush for small segments. Painting smooth surfaces is best done with a roller. It is important to ensure that the canvas is located strictly horizontally. This will allow the paint to be distributed evenly. Do not dip the roller in the solution, it is better to pour the mixture with the instrument. It is undesirable to apply foam rubber for soaking, as the paint simply “eats” it.

The easiest way is to use spray cans or spray guns. With the help of such tools, the composition is applied in several thin layers. The interval between the painting stages should be about 20 minutes. Using an aerosol, the jet should be directed at a right angle to the surface to be painted.

If you want to get the most reliable protection, then all subsequent layers should be applied after the film has gained full strength (1-2 weeks).

To learn how to apply hammer paint, see the next video.