Polyurethane paint: features of choice

Polyurethane paint is good for any surface, whether it is concrete, metal or wood. The polymer composition has not only high decorative, but also protective properties. Other types of materials have not so unambiguous characteristics. Often, the coating of the product with a polyurethane compound is precisely the function of protection against damage.

Specifications

When performing external finishing work using polyurethane enamel. This enamel increases the stability of the stone, because it creates on its surface a durable film that prevents moisture from penetrating.

Polyurethane paints have a wide range of applications: from household use to road markings. In the creation of interesting effects will help two-component compositions.

After drying, the applied composition appears attractive gloss. Unfortunately, the glossy coating underlines all roughness and unevenness, so the surface must be brought to perfect smoothness in advance. There are also enamels that create a matte surface.

The painting procedure is best carried out at a temperature range from minus 10 to plus 30. Air humidity does not play any role. Enamel is well applied to concrete, even when the humidity is close to 95%. The coating itself suffers a temperature of minus 40 to plus 150. To get a good adhesion of paint, you need to prime the surface.

Polyurethane paints can be classified according to their composition and materials for which they are intended. You can apply the paint with a brush or roller, and you can also buy paint in a spray can.

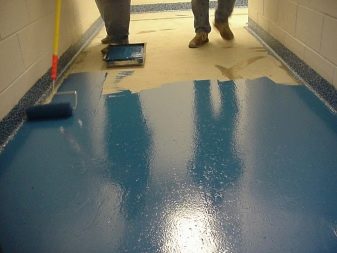

Metal products are usually painted from an aerosol. This method of painting cars allows you to get a uniform color without smudges and stains. Concrete floor is easier to paint with a roller, but it is convenient to paint wooden surfaces with a brush. Different forms of the release of the composition facilitate the task of painting an object.

Polyurethane paints are very versatile and suitable for different types of materials. Primer needed necessarily. This is especially true of metal surfaces.

Wooden surfaces can not primed, but be sure to dry them well. The tree has the ability to absorb everything in itself, so no layer is required. Paint on wood is intended mainly for furniture and furniture production.

Those who are not able or unwilling to mess with the alignment of paint layers can purchase a self-leveling version of the composition. After application, a tension is formed, which ensures uniform flow of paint, which excludes the formation of irregularities. Application method does not matter.

Composition

The paint of this category is remarkable in that it creates a strong layer on the surface to be treated, protecting the material from damage. The basis of the paint are polymers and a homogeneous mixture of hardeners and dyes. Each element in the paint contributes to the formation of a durable, moisture-resistant coating.

Often such a group of paints is sold in two separate containers, one of which contains resin, and the other hardener.

Two-component paint has advantages compared with single-component paint:

- more positive reviews than ordinary paint;

- moisture resistance;

- the ability to prepare a solution in portions, which provides an economical consumption of finishing material.

Polyurethane paint is suitable for covering areas subject to the damaging effects of the environment. Water, acids and alkalis will not harm the coating.

Kinds

The paint, which has an organic solvent, is one-component and contains pigment and thinner. It polymerizes under the influence of moisture, so in an excessively dry and warm space, the composition is not useless. The maximum durable coverage is in two days. Resistance to aggressive environment and abrasive appears at the same time. These properties have compositions for concrete.

Water-dispersion paints are also one-component, but instead of solvent there is used water. These compounds are safe for health, do not have an unpleasant smell. Uniformly distributed components of the composition after evaporation of water are bonded to each other, forming a durable smooth film.

At low temperatures, such paint will not lose its properties, but its characteristics will drop significantly. Such options are good to use in rooms with high humidity. The paint is very elastic, therefore it is suitable for plastic, rubber products and coating of parts of unusual shape (stucco molding, plinth).

Alkyd-urethane paint group is designed for painting metal surfaces, such as car body. In addition to the pigment and solvent, there are substances in the paint that accelerate drying and alkyd-urethane varnish.

The buyer can choose the level of gloss and texture to your liking. The paint has high strength and decorative properties, it is also suitable for both internal and external works. Temperature range varies from minus 50 to plus 50.

Other benefits include:

- scratch resistance;

- ease of application;

- fast drying (2 hours);

- ability to protect the material from rust.

Manufacturers Overview

Today the building materials market offers polyurethane paints from many manufacturers. The price per can depends on the brand awareness, the size and shape of the package.The most popular are German, Turkish, Greek paints. CIS countries produce products that are not inferior in their characteristics, and their prices are much lower.

Foreign formulations are more expensive. due to the high cost of transportation and brand awareness. Domestic products undergo serious quality control, have the necessary certificates and licenses. Each type of coating has its own shelf life. It does not matter what kind of coating is needed - varnish, enamel or paint. You can safely buy products of Russian brands.

Separately, it should be noted polyurethane paint from China. Celestial represents the largest market of paints and varnishes of any type and purpose.

Thus, paints based on complex polymers bear not only the function of protection and give the surface properties such as antistatic, impact resistance, anti-slip, but also improve the appearance of the coating.

What to consider when choosing?

Faced with the problem of choosing a polyurethane coating, the buyer may become confused among the huge number of options. Paints of the same purpose differ in the types and proportions of the components present in the mixture.This can significantly affect the specifications.

For example, there are enamels adapted to low temperatures. Therefore, there is a difference in surface requirements and application conditions. Keep in mind that the shelf life of some one-component formulations does not exceed 6 months.

Material Tips

Getting started, you need to carefully study the instructions for using a specific paint. Before the choice is made, it is advisable to familiarize yourself with the general recommendations regarding polyurethane coatings.

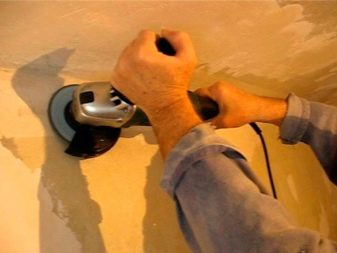

If you plan to paint the surface with an existing old paint, it is necessary to conduct a test for the compatibility of the compositions and the degree of their strength in the barely noticeable area. Old paint may start to lag and bubble. In this case, the old surface will need to be cleaned.

For maximum hitch, the surface should have a number of properties:

- It is necessary to make the surface smooth, clean and free of grease.

- Humidity indicators should not exceed 5%.

- The temperature should not be below +5.

- It is necessary to remove lagging and crumbling fragments with the use of grinding, milling, sandblasting.

- The seams must be sealed.

- If the flooring is new, it is imperative to remove the layer of cement jelly.

- The surface must be thoroughly primed.

Before work paint needs to be mixed by the mixer or manually by means of a stick. Do not let the sediment stay at the bottom of the jar. Avoid bubbles when mixing.

The extra layer of coating will not bring additional strength and may even lead to the formation of pores, bubbles and other defects. For best results, do not deviate from the algorithm instructions. Before applying the next layer, you must wait for the required time.

Paint is applied with a roller, spatula or brush. Exceptions are aerosol options.

At low humidity, drying time can be slow. The room can be artificially moistened, but not allowed to form condensation and splashes on the surface. This will cause bubbles.

Use alkaline-based products to clean painted surfaces - acids can be harmful.

Do not dispose of paint residues in the sewage system.

Beautiful examples in the interior

Paints of this group have both professional and home use.In everyday life polyurethane compounds protect the surface from moisture and mold. If you wish, the coating can be used in residential areas. After drying, it is absolutely safe for humans.

The floors of polyurethane are self-leveling surfaces, which include special two-part polymers. The resulting floor surprises with high aesthetic properties, as well as elasticity and durability. Special chemical reactions lead to the synthesis of polymers - this is how a monolithic texture of self-leveling floors is created.

Self-leveling floors are resistant to deformation, wear, abrasion, and insensitive to aggressive environments. Floors of this type are suitable not only for industrial and commercial premises, but also for residential buildings and offices.

When choosing a coating, it is important to consider:

- degree of chemical and mechanical effects during operation;

- purpose of the room;

- preparatory work to create a self-leveling floor of polyurethane;

- individual features of the room.

After giving yourself an answer to each of these points, you can proceed to the choice of design and calculation of the cost of the floor.

Epoxy urethane flooring option is used in parking lots,platforms and other similar premises due to the high degree of strength and durability.

Black glossy floor - a bold and unusual decision.

The floor resembling the palette of the watercolor artist becomes the main focus of the corridor.

Polyurethane floor can be seen in the gym.

The floor in the form of a green lawn with daisies is a good solution for a nursery.

There are lots of options in which the floor becomes the highlight of the entire room.

How to paint a concrete floor paint, see below in the video.