Hammerite paint on metal: features and types

The building materials market has a fairly extensive selection of paint products for metal surfaces. Paint, which is produced under the brand Hammerite, is a fairly popular product. It is necessary to figure out what features this finishing material has, what types of products exist.

About the manufacturer

Hammerite is an English paint brand for metal, which was launched in 1962 by Finnigans. For 55 years of existence, the products of this company has won not only the UK market, but also gained worldwide fame. Today, paint manufacturing plants are located in several countries, including Turkey, Bulgaria, Argentina, Brazil, and Uruguay. The company is constantly working on the quality of its products, applying the latest developments in the field of paint coatings.

Special features

Hammerite paints are designed specifically for various metal surfaces.They have several advantages. Thus, the products meet the highest quality requirements for the products of the chemical industry. The composition of paints has the formula 3 in 1. This means that, in addition to the coloring pigment, there are substances that protect the metal from corrosion, as well as a primer, so there is no need to treat the surface with additional primer solutions.

The coating that forms this material is quick-drying. To "grapple." the applied layer is just 30 minutes. The coating receives its initial strength after 3 hours, the full acquisition of properties is achieved in 6 days. It is possible to apply a covering both a brush and the roller, and an airbrush. A fairly wide range of colors makes it possible to use paint in almost any design. In addition, it does not have a sharp smell.

The disadvantages include only the cost of production, but this ratio of price and quality is optimal.

Kinds

Hammerite paint is available in several types.

Hammer effect

Coating, which is intended for the processing of ferrous metals. When drying on the surface of the product is formed an imitation of hammer embossing.This was achieved by adding to the composition of the flakes of aluminum. The product perfectly hides the irregularities of the metal, when tinting areas, the transition is almost imperceptible. Suitable for rust without pre-cleaning. Also, in the manufacture of paint wax is added to the composition, which additionally protects the surfaces treated with this composition from moisture. This product has a heat resistance, withstanding temperatures up to 80 degrees. Suitable for painting fences, gates, various garden tools. The cost of the product is about 2500 rubles for 2.5 liters.

Smooth glossy base for tinting

This coating is suitable for indoor and outdoor use. The composition, in addition to wax, also includes silicones, which provide additional protection against corrosion. A large assortment of colors makes it possible to create the desired shade of paint. The paint gives the surface a glossy shine. The cost of the product is about 850 rubles for 0.7 liters.

Smooth glossy

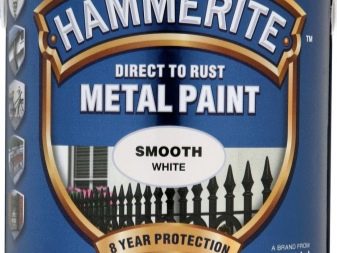

The product already contains color pigment. Suitable for both previously painted surfaces, and for rusty, unpainted.It has a high resistance to such natural factors as negative temperatures, rain, snow. Does not fade when exposed to ultraviolet rays. It has an extensive selection of shades. Here you will find 17 color options: from white to black. The cost of the product is about 2000 rubles for 2.5 liters.

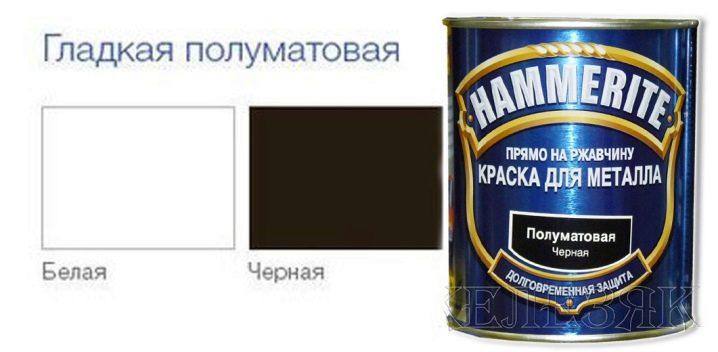

Smooth semi-gloss

Unlike the previous product, the layer that forms the paint is matte. In addition, the paint has refractory properties. It can cover heating radiators and hot water pipes. The product is available in white and black. The cost of the product is about 2,200 rubles for 2.5 liters.

How to apply?

The manufacturer provides a guarantee of coverage for more than eight years, subject to the technology of metal processing.

Here are some tips to consider when applying this product to surfaces:

- First you need to prepare the selected surface. To do this, you must clean the metal from various contaminants, degrease.

- After opening the jar, the composition must be well stirred. After mixing, it is worth leaving the paint for a few minutes so that the air trapped in the jar comes out.

- The temperature of the treated surface and the environment must be at least +5 degrees and not more than +30 degrees. Humidity should not exceed 70%.

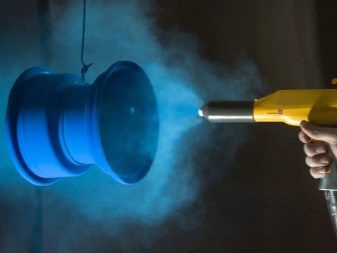

- For painting welded surfaces, such as benches, fences and the like, use a brush. For large staining areas, it is better to give preference to a roller or spray gun.

- Brush is better to choose high quality with natural or blended pile. This is because Hammerite products contain an organic dye that can dissolve synthetic bristles.

- 2-3 dyes should be applied to the surface at intervals of at least 30 minutes.

- For vertical surfaces, the layers should be as thin as possible, but there should be at least three.

- When applying paint brush to dilute the composition is not required. When working with a roller, the product should be diluted with a special solvent and a Hammerite cleaner with respect to the solvent-paint 1: 10. When working with an airbrush, this ratio should be 1: 7.

- Since the thickness of the coating changes upon dilution, it is worthwhile to increase the number of layers to at least three or four.

Reviews

Reviews of Hammerite paint are good.Buyers talk about a thick consistency, which allows in some cases to do with just one layer. In this case, the coating is quite resistant, it does not climb, it is not erased. Many note the beauty of the coating, which creates a paint with a hammer effect. Also, buyers notice that the paint does not smell much, dries quickly. The product is easy to apply, does not spray, no drips form. Negative reviews only about the cost of paint Hammerite. Many are not ready to give such money for this product, even if it is so high quality.

All about Hammerite paint on metal, see the following video.