What paint to choose for concrete surfaces?

It is difficult to imagine construction without the use of concrete. Foundations, floor screeds, walkways, stairs, floor slabs - this is only a small number of applications of this building material. It is associated with something durable and reliable, but few know that without some protective measures, concrete is quickly subject to destruction.

Coverage Features

The need for additional protection is dictated by the characteristics of the concrete pavement.

First of all, the positive aspects of this coverage are:

- The popularity of concrete does not decrease due to its durability and strength: hermetic and properly treated floors or walls can last almost forever. The strength of concrete is in principle a variable indicator, because it grows as it hardens and does not stop when the standard period of 28 days is reached.

- Concrete withstands heavy loads without deformation and destruction.

These qualities make it especially popular in industrial buildings and construction of household facilities (warehouses, garages, etc.).

- Ease of maintenance is another nice bonus to concrete surfaces. Enough timely update of the protective layer every 3-9 months, depending on the means used.

- Environmental cleanliness also adds points to this material.

- Radioactivity of concrete is less than that of a brick. But theoretically, the concrete components can be contaminated, so you should choose the proven manufacturers and check the documents for the goods.

- Being a versatile material, concrete can be used as an independent surface or as a basis for a decorative coating.

With all its positive qualities, concrete, however, is susceptible to corrosion.during which the structure of the material is destroyed. The main enemy is water, which easily penetrates into the pores of the coating, dissolves and washes away easily soluble components (hydrated lime). Excess moisture is especially harmful at low temperatures. Freezing water mechanically destroys the connection between the components, which affects the strength.

Acidic environment is not less harmful, as it can cause both leaching of lime compounds, and promote the formation of insoluble calcium salts, which, accumulating, increase the volume of concrete and provoke cracking. It should be mentioned another factor - biological.

The porous structure of concrete is attractive to microorganisms, and their waste products are destructive to it.

To level the negative effects allows protection in several stages. The primary protection is the introduction of stabilizing and sealing substances into the mixture, which slow down the action of aggressive reagents. Secondary protection is the application of paints, primers, mastics and other secondary materials.

Types of paint

The lack of paintwork materials for concrete today is not observed, and the options vary in composition and properties. The question is only in quality and compliance with operating conditions.

Alkyd paint

Alkyd paint is a type of enamel paint, which after curing forms a strong and elastic film on the surface. It is universal, suitable for almost any surface: wood, metal, concrete.

High resistance to weathering, water repellency and resistance to temperature extremes (from -50 to 60 Co) allow it to be used for outdoor work. Equally easy to apply with a brush, roller and spray gun. Average drying time: about 24 hours. Alkyd enamel applied in 2-3 layers retains protective properties for up to five years. Another significant plus is the low cost.

Of the minuses should be noted its toxicity in the liquid state., flammability and airtightness. Excellent adhesion makes it difficult to remove. All existing washes only soften the coating, which is then removed with a spatula.

Acrylic paint

Acrylic paint is one of the universal favorites on the building materials market, which is a water dispersion based on acrylic resins. When it dries, a polymer film is formed on the surface, which, unlike alkyd based dyes, easily passes air.

The paint forms a wear-resistant, waterproof, heat-resistant, non-flammable and environmentally friendly coating. It is completely non-toxic and odorless, since there are no organic solvents in its composition.

Easy to apply and dry within a few hours. As a rule, the second layer can be applied after 2 hours.

It can be used at high and at low (but not below zero) temperatures. The number of layers is desirable to do at least two. A large variety of colors and textures of this option allows you to solve any design problem.

Silicate paint

Silicate paint is a kind of mineral dyes, the main binding element of which is liquid potash glass, which gives the final coating high strength. As additional components that improve the properties of the material, there is a silicon powder, zinc or aluminum. The presence of these metals increases the anti-corrosion properties of the dye.Liquid glass and dry pigment mixture are supplied separately and connected immediately before use.

This is one of the most durable coatings. (can serve at least 20 years), while at the same time it retains its original appearance over the entire life cycle. It is resistant to ultraviolet radiation, sharp temperature fluctuations, moisture and pollution, it is chemically resistant.

This paintwork material forms the strongest compound with mineral-based surfaces (concrete, stone, glass, plaster). Often used for facades and other exterior works.

Among the drawbacks, it is worth noting the inelasticity of this dye, that is, small cracks cannot be repaired. Therefore, the foundation must be perfectly prepared. High toxicity of paint requires the mandatory use of personal protective equipment. Adhesion to the surface is likely to cause problems when removing silicate enamel.

Silicone emulsion paint

Silicone emulsion paint is almost close to the ideal. When cured, a waterproofing, vapor-permeable film is formed that maximally protects the base from moisture.Plus, it is elastic, durable, wear-resistant, and also adheres well to concrete and other mineral bases. Resistance to alkaline environment allows you to apply it on concrete and plaster after two days, while acrylic paint can be used no earlier than in a month. The only negative is the high cost.

The ability of silicone-based resins to bind well with acrylic polymers made it possible to obtain a new group of silicone-modified paints. They are characterized by better properties than classic acrylic, but the price is lower than that of silicone options.

Rubber paint

Rubber paint - a relatively new type of paint and varnish materials, has won the reputation of durable and durable enamel. In the liquid state has the form of mastic, which when dried forms a film resembling rubber. In its composition is present acrylate latex, giving the composition elasticity and strength.

The solvent is plain water, which indicates the environmental safety of the product. The paint is characterized by good adhesion with various types of surfaces, including concrete, plastic, metal,wooden. She is not afraid of temperature fluctuations: all properties are stored in the range from - 50 to +60 C.

Rubber paint can be applied in any way. Some manufacturers produce it in cans. Drying is very fast: after 2 hours the surface is ready for further work.

Rubber film has anti-slip effect.

Elasticity and flexibility allows it to change with the base without breaking the integrity. Acrylate-latex-based paint often serves as an additional hydro-insulator, for example, in the construction of swimming pools. Resistance to mechanical stress allows you to use it for drawing road markings (preferably using reflective), for finishing children's playgrounds, stadiums, gyms. The term of operation is 8-10 years.

Polyurethane paint

Polyurethane paint for concrete surfaces is most often used as a floor paint. The thick elastic film formed after solidification effectively protects the floor from mechanical, chemical and weathering. Polyurethane paints are one-component and two-component. The latter option is more common and is sold in two containers.A hardener is supplied in one, and a resin in the other.

A distinctive feature of paints of this type is the possibility of applying at temperatures from -10 to +30 C and at high humidity. Moreover, humidity is one of the conditions for solidification of this material. Service life - from 10 years.

Epoxy enamel

Epoxy enamel is a two-component paint made on the basis of epoxy resins. Today it is considered one of the most durable and wear-resistant coatings. Depending on the type of resins and their proportions with hardeners, compounds with different properties are obtained: from rigid to flexible. Epoxy based paints are versatile, they adhere strongly to all types of surfaces.

Among its analogues, it stands out resistance to the effects of any orientation: chemical, atmospheric, mechanical, biological. Epoxy coating retains its original appearance for the entire life. The only negative is its two-component. Mixing the components, it is easy to err in the proportions, which will not allow to obtain the desired result.

How to choose?

For paints on concrete, it is important to have the following characteristics:

- Resistant to mechanical damage;

- Wear resistance;

- Fire resistance;

- Heat resistance;

- Water resistant;

- Chemical resistance;

- Lack of pungent odor;

- Environmental Safety;

- Easy to care.

Unfortunately, the ideal product, which equally combines all these qualities, has not yet been invented. Therefore, the choice depends, first of all, on the purpose of the room. Before going to the store is to assess the intensity of use of the concrete surface. For example, the requirements for a garage floor paint will be higher than for a similar material for a window sill, balcony or wall.

When choosing paint, you must also keep in mind the type of work:

- For interior work, non-toxic and environmentally friendly compounds are appreciated. The absence of a strong odor will also be a plus, as it will allow to paint poorly ventilated rooms without any problems. The durability of the dye in the case of interior decoration will be important for production facilities and large marketplaces where there are high mechanical loads on the floor.

- For exterior finishes, the toxicity index is not decisive.Here it is important that the finishing material is resistant to all kinds of influences: physical, chemical and biological.

- The positive point is that many of the products on the market are universal. Therefore, before buying you need to carefully study the labeling of the product, its composition, properties and recommendations for use.

Tips and tricks

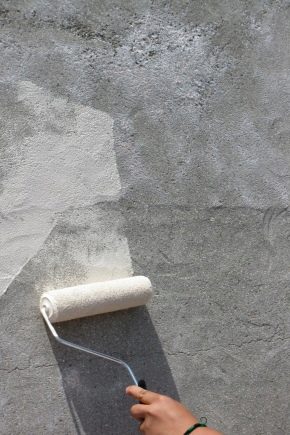

An important condition for the successful painting of concrete, however, like other surfaces, are the preparatory work. At this stage, carefully remove dust, dirt, paint residues, grease stains. When re-staining, it is advisable to go with a grinding machine to remove the destroyed upper layer. Inspect the treated area for defects, remove the detected violations. By itself, concrete has low adhesion (especially for low-quality grades), therefore, it is treated with primer-paint for better adhesion to the finishing material.

Famous manufacturers and reviews

Among paintwork materials on concrete on hearing polyurethane paint Texil. Almost all customer reviews are positive.For users, it was unexpected that at a relatively low price, they received a durable coating with good performance.

Polymeric and acrylic floor paint "Betoksil" - Another good brand for industrial and civil use.

Durable and wear-resistant, it is suitable for painting at low and even negative temperatures.

Finishing material brand "Aquapol" it is used on objects where usual or average loading is supposed. Suitable for rooms with high humidity.

Elakor - These are polyurethane paints, which can be both one- and two-component. They are allowed for use in food and pharmaceutical enterprises, as well as in residential premises.

How to paint the concrete surface on the street, see the following video.