Features choice Tarkett laminate

When choosing a floor covering, buyers first of all think about its visual appeal and compliance with the design of the room. This approach allows you to design an interesting interior, however, it is not always justified in the course of operation, because the floor covering is subjected to significant loads and must withstand them with honor. The use of such laminate as Tarkett allows to combine aesthetic appeal with practicality and durability.

Production technology

Today Tarkett manufactures exist in many countries of the world: in Germany, Sweden, France, the USA and Russia. All floor coverings of this brand have certificates of compliance with EU safety standards. Moreover, the laminates produced in Sweden, Germany and Russia are marked with such an international environmental sign as the “Leaf of Life”. This marking means that, although Tarkett materials contain PVC, they do not emit harmful fumes, do not have formaldehyde, and in the process of their production no harmful solvents are used.

The structure of laminate Tarkett

The wooden laminate flooring manufactured by Tarkett is not only comparable in strength and durability to natural parquet, but, in some characteristics, is able to surpass it. Such strength is achieved thanks to the technological features of production at the enterprises of this brand.

Usually in the manufacture of laminate board, several layers of material are pressed, between which there is an adhesive film of resin. Such layers can be from two to four, depending on the level of the manufacturer and the technologies used.

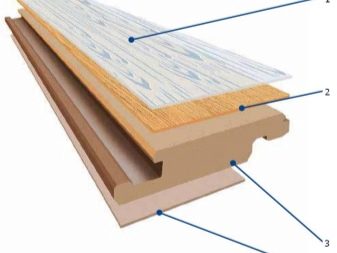

Tarkett laminate board consists of four layers. The lowermost layer is designed to protect the structure from deformation and increase such characteristics as its rigidity.

In some cases, the lower layer is completed with a noise-insulating substrate, which the manufacturer considers necessary to install for additional sound insulation of the floor.

The main part of the board is represented by a carrier layer. It is made of HDF board, which in its composition is similar to MDF board, but is stronger and more durable. It is produced by pressing small sawdust and wood dust, glued with lignin and has a strength of 920 kg / m3.

For maximum strength characteristics, HDF plates are impregnated with waxes or silicone-based compounds, which ultimately increases the service life of the product and gives it water resistance. At the same time, castle joints are also impregnated with wax-based compounds. The Tarkett brand is the author of this development, and today such an additional protective coating, called Tech3S technology, is used by many laminate manufacturers.

HDF-surface is covered with a decorative layer, which is made of thick paper, having a color and embossing "under the tree", or imitating a natural stone floor. Then, the upper covering layer is cast, which is made of melanin or acrylic resin, on which decorative embossing is also performed, imitating the pattern of natural material.

The structure of the vinyl laminate Tarkett

In addition to wooden laminate, the company produces Tarkett so-called "vinyl laminate" or "vinyl tile." This laminate also has a complex structure and consists of several layers:

- The bottom layer, which is made directly from vinyl, ensures the strength of the product;

- The middle layer consists of ceramic granite, also filled with vinyl mixture;

- The top layer of polyurethane or aluminum oxide has a decorative value, it is usually made in the form of an imitation of the surface of wood or stone;

- Between all the layers there is a glass fiber substrate that performs a reinforcing function;

- The surface of the tile is covered with an additional protective layer for durability.

Pressing all layers under high pressure turns them into a monolith, which has unique characteristics of resistance to moisture, dirt and abrasion. Externally, the vinyl laminate looks very similar to its wooden "relative", with one small exception - it is sensitive to the rubber shoe soles, which leave whitish traces.

Collections and their characteristics

Considering the technical characteristics of Tarkett laminates, it is worth paying special attention to both the features of the wooden board and the advantages of the vinyl version, since these varieties have significant differences.

Tarkett wooden laminate can be matte or glossy, have a surface "under the tree", including aged, or under the stone. Also externally, he can imitate parquet or ordinary board.

Sheet laminate is in the form of one or two boards, separated by a pattern or a facet. A chamfer is a recess, which is present on the long sides of the board, which looks like the removal of the edge on a wooden canvas and adorns the general appearance of the floor.

The characteristics of the laminate differ depending on the groups and the collection, but there is something in commoninherent to the products of this company:

- The presence of Tech3S protective coating, which increases the service life of the board and facilitates the installation of the coating;

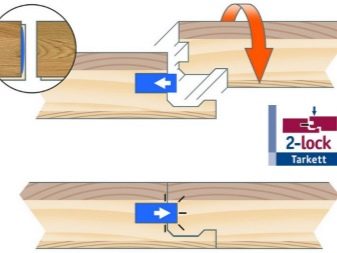

- Assembling the board using the lock joint TC`Lock, which allows you to join the board in width without visible seams.

More detailed specifications vary depending on the characteristics of the various collections.

The Tarkett Art laminate group includes 3 collections, related to wear class 32 and 33, with a maximum service life of 25 years, designed for installation over warm floors and having the following characteristics:

1. Gallery - this is a collection including a laminate having a board thickness of 12 mm, a chamfer and a reduced board width of 116 mm;

2. Ballet, Cinema, Intermezzo - these are collections, the laminate of which has a thickness of 8 mm, a four-sided chamfer, a width of 194 mm, some specimens have a deep expressive texture due to the embossing in the register;

3. Estetica, Artisan have 9 mm board thickness, the standard width is 194 mm and will delight buyers with features such as:

- the effect of the execution of solid wood, which is provided by the presence of four-sided optical chamfer;

- the external effect of manual processing of wood;

- effect of aged wood.

4. Lamin'art, Vintage have a thick board with a thickness of 9 mm, whose width is 194 mm, and are equipped with a lock of the new 5G system (2-lock); the effect of the array, manual processing and deep expressive structure reinforce the impression.

Family Group offers 3 laminate collections, intended to be installed over warm floors, the maximum service life of which is also defined for a period of 25 years, belonging to 32 and 33 classes and having traditional characteristics:

- Woodstoc family it is 8 mm thick, 194 mm wide and stands out for its deep, expressive structure and embossing in the register;

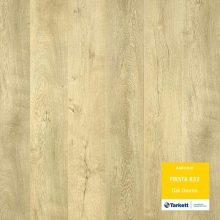

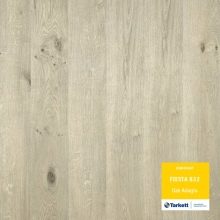

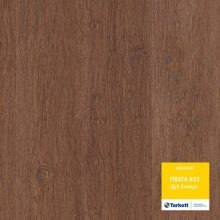

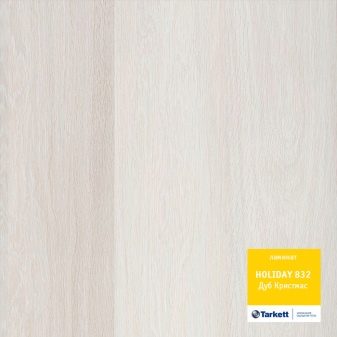

- Fitsta, holiday have a standard thickness of 8 mm and a width of 194 mm, differing in relief and volume embossing "under the tree";

The collections included in the Traveler series, also designed for a service life of 25 years, fall into the 33rd class of durability and have an increased board thickness:

- Pilot has a board with a thickness of 10 mm and a width of 159 mm; in addition, the laminate of this collection highlights the presence of expressive embossing, 4-sided chamfer and the effect of processing by hand;

- Navigator it features an extra thick board of 12 mm, which has a standard width and an embossed surface;

- Robinson has a board thickness of 8 mm, its width is 194 mm, however, being a two-lane, this laminate looks very exotic,which is emphasized by the presence of glossy shine;

- Odyssey, riviera are classic versions of 8 mm laminate;

- Monaco will delight the buyer with a particularly powerful board of 14 mm, which has a standard width.

Vinyl laminate, as stated by the manufacturer, is a good combination of parquet beauty, practicality of linoleum and modular tile features.

In the category of Art Vinil products, customers are offered 4 collections belonging to 32, 33 and 34 classes, differing in design and having similar characteristics:

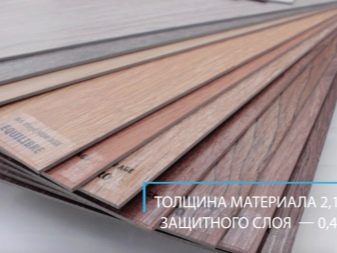

- The thickness of the tile can be from 2.1 mm to 3 mm;

- The thickness of the transparent protective layer EXTREME PROTECTION ranges from 0.4 mm to 0.7 mm;

- High resistance to the effects of furniture legs, heels and roller chairs;

- Possibility of laying over warm floors;

- Low water absorption;

- Noise protection;

- Abrasion corresponds to GOST 11529;

- Resizing during operation is 0;

- The presence of special effects, such as the unique design of the Murano collection, the four-sided chamfer characteristic of the Lounge collection or the realistic relief that distinguishes the Jazz collection.

Customer Reviews

Tarkett board-laminate has uniquely positive reviews from both buyers and handing specialists.They note that the price tag for the laminate produced in the Russian Federation of this brand is much lower than the German one, although the quality can be called equivalent. An important point is the fact that the life of such a coating depends largely on the correct installation, since, being a natural material, the laminate board can “walk” when humidity changes. This should be taken into account when laying, leaving gaps in the places of attachment of the plinth.

Buyers are satisfied with the presence of water-repellent impregnation at the board of this manufacturer, which is especially important in places of fastening of locks. It is also noted that Tarkett laminate is easy to clean, tolerates wet cleaning, but you need to wash such floors more often, because they are well visible dust.

Vinyl laminate, which today can still be called a novelty, has conflicting reviews. Some buyers are completely satisfied with how this coating manifests itself in the process of exploitation, but there are categorically dissatisfied remarks. Claims are made to the fragility of the surface, which does not withstand the pressure from the heels and thaws under the legs of heavy furniture.

On the water-repellent characteristics of vinyl laminate reviews are very positive, buyers definitely recommend to lay it in the bathrooms and the kitchen.

Where is it used?

Such a floor covering as Tarkett's laminate is widely used for the decoration of rooms with different uses, but requiring practical, high-quality and aesthetic floors. These can be audiences of educational institutions, kindergartens, hospitals, boutiques or ordinary living rooms. In rooms with high humidity, for example, in bathrooms, you should not lay a wooden laminate floor, it will swell up and “swell up” with abundant moisture.

Depending on how high the permeability of a particular room differs, it is recommended to select a laminate class and board thickness:

- For such household premises as a bedroom or a dressing room, there will be enough laminate of 32 cross-country classes, having a board with a thickness of 8-9 mm.

- In the nursery it is better to lay laminate 33 class 10 mm thick, this coating will withstand children's jumps and games.

- The corridor and the hallway can be covered with laminate of the highest degree of terrain, belonging to the 33 or 34 class.

- Also covering 33–34 classes of terrain is covered by public spaces, using the thickest board from 12 to 14 mm.

Tarkett vinyl laminate is moisture-resistant, so it can be safely laid in bathrooms and in the kitchen. Such a waterproof coating will create a pleasant impression of a warm wooden floor, without creating problems with the appearance of mold and soaking floors with leaks from the plumbing.

The question of the use of laminate in the arrangement of a warm floor today remains open. Officially, the manufacturer recommends the board company Tarkett for laying out on a warm floor, but stipulates the maximum heating temperature. If the buyer is absolutely sure that his warm floors will not overheat above + 27 ° C, then it is possible to use laminate for such structures.

In most cases, as customers indicate in the reviews, it’s not worth risking installing laminate on a heated floor, as the seams crack and overlay from overheating.

Piling

Since Tarkett laminate is wooden and vinyl, the way it is laid will differ depending on the material.The manufacturer attaches to each type of laminate detailed instructions that suggest in what conditions and sequence the installation of this coating should be carried out. However, it is better to entrust this work to professionals with experience.

Laying laminate in the form of wooden boards involves the following stages of work:

- The preparatory stage, during which the specialist stacker eliminates the shortcomings of the floor: its curvature, cracks, chips and pits. For this, a base screed is made, or plywood is laid.

- Tarkett vapor barrier substrate is laid on the dried screed, which is fixed with adhesive tape along the docking line.

- Wedges must be installed between the wall and the first board, which will subsequently be removed during the installation of the plinth. The end sides of the board should also not be installed close to the wall, therefore wedges are necessary there as well.

- It is advisable to use a chess pattern when laying, as a result, the floor looks particularly beautiful. Excess boards are cut with a hacksaw and installed at the beginning of the next row.

- Low-quality laminate strips should not be installed, they can always be returned to the store and exchanged for new ones, therefore in the process of laying it is necessary to carefully inspect the locks.

- The beginning of laying laminate is the process of docking strips along the length, which is carried out by combining locking joints.

- Subsequently, the joining of the transverse and longitudinal joints occurs sequentially for each bar.

- When installing Tarkett laminate there is no need to lift the previous layer to fix the locking connection, therefore the probability of breakage of the slats is minimized.

Vinyl laminate during installation must be glued to the floor, and only installation on a concrete screed is allowed.

The main stages of work:

- Seal the cracks and prime the base.

- Laying vinyl tiles is carried out on acrylic glue, which dries very quickly, respectively, it should not be applied a lot, so as not to remove.

- Laying is carried out in accordance with the directions indicated on the tiles. For modular designs, it starts from the center of the room, but for other models, you should follow the method indicated in the instructions.

- Each glued tile is rolled with a heavy roller.

- It takes 3 days to completely dry the coating.

For more information on how to lay vinyl laminate, learn from the following video.

Colors

In the collections of classic wooden laminate Tarkett you can find a variety of colors of wood and stone, the description of which is worthy of a full-fledged study, since each shade is associated with the theme of a particular collection.

Most often in the colors of Tarkett laminates there are various oak variants:

- Bleached Oak Sinsero;

- Sunny oak Osorno;

- Natural Pyrenean Oak Adagio;

- Brown oak Kalido and Castano;

- Oak Sherwood various shades;

- Oak effect honey;

- Light oak Kristmass and many others.

You can also find:

- Several shades of bright pine, for example, Randwu pine, Himalayan or Alpine pine.

- Many shades, unique to this brand, whose names depend on the direction of the collections:

- pale ashen wood surfaces called Giselle, Sylphide and Esmeralda;

- honey-colored surfaces Spartak, Giselle and Canon;

- Monet, Greco, Degas, Da Vinci gray-blue tones;

- the complex colors of the aged surfaces of Audrey, Bridget or Dietrich;

- brown colors: Hermitage oak, Louvre oak and Prado oak;

- brushed oak, which is called Rohide and Wuven;

- exotic woods such as Japanese chestnut or Tanzanian wenge.

Examples in the interior

When interior design, you can pick up a laminate of a lighter tone in a dark room, in order to make the space more voluminous and attractive. Sunlight will help the bedroom to help Sherwood Honey Oak from the Woodstoc Family collection. Externally completely indistinguishable from natural wooden boards, this laminate can be combined in any of the modern or classic design trends.

It looks especially harmonious in a minimalist style, since, due to the absence of unnecessary interior items, a unique tree pattern and its deep expressive fiber structure are visible. When creating such an interior, you can use a light sand color scheme for painting walls, a dark broad baseboard for decorating the contours of the room, designer furniture and lamps.

Magnolia laminate floor is a model of a classic approach to the design of residential premises. Soft transitional shades from the Robinson collection are versatile and suitable for both a work office and a cozy living room decorated in a modern style.

Due to the presence of honey and cherry tones in the color of the laminate, it is possible to arrange the furniture in a room with such a floor completely, seemingly incompatible in color. For example, a wenge-colored coffee table and a gray sofa. The walls of the room can be made in any of pastel shades, the color of the floor covering allows it. It will harmoniously add walnut-colored doors and huge “French” windows to the interior, extending the room.