The choice and laying of a heat-insulated floor under a laminate

A few years ago, it was impossible not to dream of installing laminate on a warm floor. Laminate end of the last century under the influence of high temperatures was covered with cracks and came in the wrong form in a short period of time. But that has changed over the past decade.

Specifications

Each building material has its pros and cons. Some have ceramic tiles, others have natural wood boards, and still others have laminate. First of all, this coating attracts with a democratic price and universal application to any interior.

Modern laminate can be put not only in the version with a warm floor. But even in the rooms high humidity - in bathrooms, in kitchens and in pools. It is no secret that the warm floor, as a rule, is mounted in these places.

Under the laminate flooring will be optimal with a temperature of about twenty-five degrees. By the way, some poor-quality types of this building material at high temperatures begin to emit formaldehyde. This substance is contraindicated for allergies and may adversely affect the health of young children.

On any packaging from laminate special markings are placed. Each of them is responsible for a specific characteristic of the building material. The inscription "Warm water" (in the English version of Warm Wasser) guarantees a combination with a heated floor.

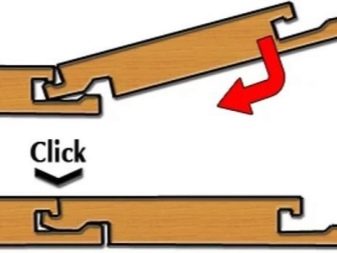

Lock laminate Click provides not only reliable fixation, but also is responsible for such characteristics as thermal insulation and sound absorption. From this it follows that the warm floor will not lose its effectiveness, for no reason a single degree will disappear into the air.

Before you put the laminate on a heated system, any buyer will be useful to study this topic at least superficially.Otherwise, you can lose money and nerves.

Kinds

Heated floor can be used in premises as an addition to existing systems of heating, and in a separate independent form. To date, there are two types of warm floor - it is water and electric.

At the beginning of the last century, thanks to the invention of the water pump, the first kind of a warm floor appeared. The source of heat was hot water that circulated through copper pipes. The equipment was not cheap, so the system did not receive proper widespread use until the 1980s.

After replacing the iron pipes with polymer ones, it was possible to reduce the cost of the finished product. This led to increased demand, and the warm water floor began to appear massively in European homes.

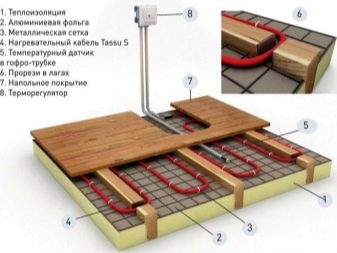

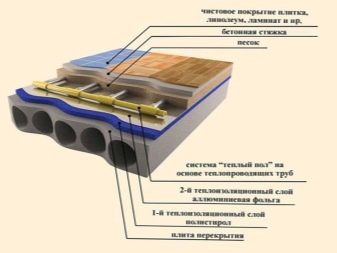

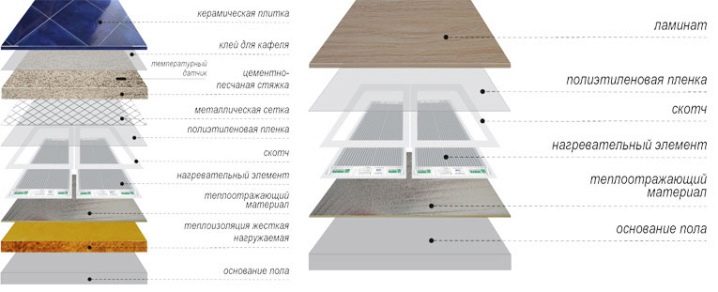

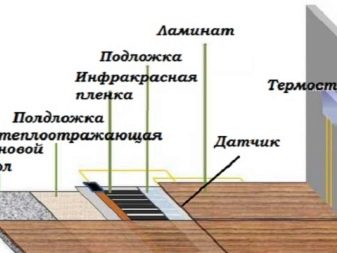

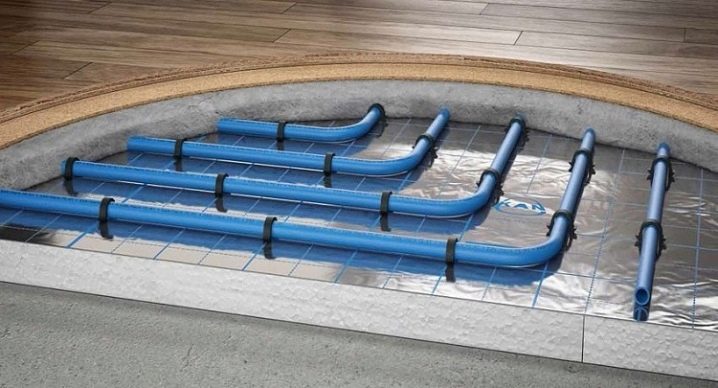

Modern water-heated floor is a heat-insulating layer with a metal grid and aluminum foil, which is laid tubular corrugated system. Two devices are responsible for the temperature. Under the laminate - a sensor, and on the outside - the thermostat.

Water at a certain temperature circulates through the tubes due to the operation of the pump.It can be brought from the riser - this is a good solution for bathrooms and kitchens, as well as from central heating - in all other cases. In exceptional cases, it is possible to operate the system without a pump.

The warm floor, based on the hot water circulation system, despite its advantages - the democratic cost of the product and the low cost of installation, It has its drawbacks:

- when pouring the screed it is easy to damage;

- in urban apartments there may be problems with neighbors, it is possible to flood them.

Therefore, in prefabricated homes prefer electric floor heating.

A heating cable with a resistive resistance was patented about a century ago. The Norwegian company Nexans was the first, it also owns the world record. Back in the late 1930s, one of the first electric floor heating systems in the city of Oslo was installed. She worked without failures until the beginning of the millennium, after major repairs in the room, the system was replaced with a new one.

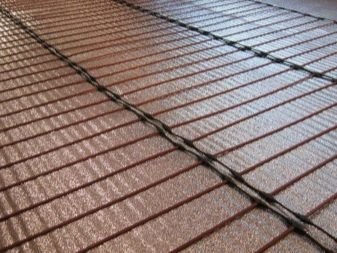

Over the past decades, the electric version of the heated floor in every way developed. Today, its varieties are known - cable, film and rod.

The principle of operation of the cable electric floor is based on the wires of special alloys. Experts have developed wires so that they convert energy into heat, and the temperature control is responsible for the temperature.

Such a system is different long service life and low power consumption. Of the minuses can be called a high cost of installation. Cheap kits are likely to generate electromagnetic radiation. High-quality underfloor heating is marked with ISO 14000 and KIMA.

In film electric floor heating, the principle of operation is based on a specially developed carbon film. Under the action of electric current, its elements are heated, producing infrared rays and emitting anions. Radiates directly paste on carboxylic basis. It is applied either straight or curved lines.

In expensive models, continuous application is practiced, which ensures heating of the entire working surface area. The temperature is set using the thermostat. This roll floor is able to lay any adult.

Unfortunately, due to the presence of a huge number of hidden contacts, periodic failures can occur. Additional expenses are possible - purchase of connectors.It is necessary to carefully observe the installation technology.

Rod (carbon) electric underfloor heating has appeared recently. But during its existence, it has established itself as a reliable and environmentally friendly building material. Korean scientists have come up with a system that works on carbon rods. Directly in stores mats with “intellectual filling” are sold.

Thermomat has the following advantages:

- Strength. Its elements do not break under the weight of household appliances and large furniture. Self-regulating infrared floor heating reduces the possibility of local overheating.

- Compatible with any kind of screed. His contacts do not deteriorate, the system does not fail.

- Moisture resistant. Rod floor can be installed in bathrooms, loggias and terraces.

- Ecological safety.

- Self-regulation of temperature allows you to control power consumption. Energy-saving floors are installed not only in city apartments, but also in country houses. Even wealthy people are not willing to waste money.

Like any new product, economical carbon warm floor has a high cost.Due to this, fraudsters are also activated, releasing counterfeit goods. You need to be very careful when buying.

The substrate under the warm floor should be of low thermal conductivity. In this regard, polypropylene and extruded polystyrene foam are most often used as the basis.

If the substrate can withstand high temperatures - ninety degrees, then the screed is optional. It should be remembered that the substrate helps to save electricity, because it does not let the cold air from the concrete walls.

Dimensions

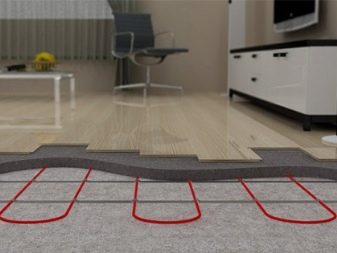

Even the thinnest warm floor after its installation reduces the height of the room by a few centimeters. Thickness may depend on the presence or absence of the screed. Do not forget that the laminate will “take” a few centimeters to itself.

Experts recommend to lay the warm floor in the first place, and already install interior doors - in the second. Otherwise, the doors will have to be reduced, and these are additional cash and temporary expenses.

Which is better?

Of the existing varieties of warm floor is very difficult to call one that is suitable for all people. A universal option simply does not exist.Each type has its pros and cons. And everyone will have to choose, based on their preferences and financial condition.

But when making a choice, you need to know that there are basic characteristics that must necessarily be in the product:

- Uniform heating of the surface. Today, outsiders in this category are water and cable underfloor heating. With regards to the cable, the temperature is higher in the places where it is located, and it is difficult to heat the water-heated floor in large rooms.

- No harmful secretions. Unfortunately, the cable heating system often emits electromagnetic fields, the other "representatives" are not noticed.

- Ease of installation. For cable floor heating need screed and special glue. The installation takes up to three days, and direct operation will begin only after fourteen days. The infrared floor is put into operation immediately after installation and a screed is not required for it. And for the device of a water floor in city apartments and at all permission is required.

- Stable performance. The infrared system in the event of a breakdown at some site does not affect the operation of the entire underfloor heating, unlike competitors. Cable floors and completely fail.The breakdown of the sensor in mats also leads to de-energization of the entire system, and a decrease in pressure in the water one - a guaranteed decrease in temperature.

Products can be laid on the concrete floor with any heating system. Under the vinyl laminate fit all systems except cable floor heating, on the chipboard - too. Under the cable warm floor only ceramics and granite are suitable.

Summarizing, we can conclude that infrared heated floors are best suited for urban apartments. Although they will have to pay more money for them, permission to install is not required.

It is more expedient to install infrared heat-insulated floors in country cottages, saving money during operation is substantial. Since the power consumption is minimal.

If after years of operation the infrared floors cease to arrange their work, they can be easily replaced. Provided that they were laid without a screed and above them a floor made of fibreboard laminate with Click lock.

How to lay?

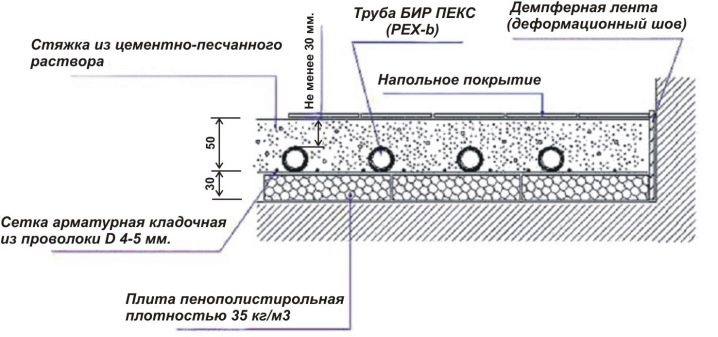

Laying a warm water floor begins with the correct calculation. It is necessary to calculate how much exactly the corresponding parts of the product will be required.The water circuit should not have any connections, it fits whole.

For the calculation, it is necessary to know the exact distance of the distance between the tubes, the smaller it is, the more building material is to be. In this case, the installation method is not important, the flow rate will be the same. A small step is 10 cm, it is necessary to do in those rooms where the warm floor is the only source of heat.

Maximum length of solid connection must not exceed seventy meters. This area is enough for laying about seven meters, respectively, for heating a standard city living room you need three such water circuits.

The position of the furniture in the room also influences the footage; there is no need for communication under it. We need to retreat from the walls and partitions of about twenty centimeters. The resulting difference will be the final length.

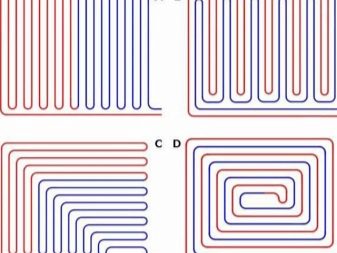

There are several ways of laying a warm floor on a water heating system, of which the most popular are - "snail" and "snake".

The first method of laying can be done by hand. But this method has a significant disadvantage - low heat transfer, so it was not widely spread.The second type of laying is more effective, but, as a rule, it is carried out only by professionals, since a certain skill is needed.

You can lay a regular and double "snake". Proper installation eliminates the appearance of cold zones. To facilitate installation, you can use spetsmata, and to fix the snake - special elements. It must be remembered that the pipe will expand and contract at the moments of heating-cooling. And from this it follows that you need to fix with a little relaxation.

After installing a warm water floor will only fill it with a concrete screed. Damper tape will help avoid cracking at the highest temperature point. Joints must be sealed with construction foam.

The compensation layer prevents the formation of moisture, so the coupler does not crack in time. For the installation of pipes fit either reinforcing or plastic mesh. Fixation is due to the harpoons. Before pouring the concrete, the working pressure has yet to be submitted so that the entire system is aligned.

There is another way of laying a water floor. It is based on a polystyrene mounting system.Pipes are stacked on spetsmaty and fixed with snaps. The installation method is very simple, the red pipe is responsible for the flow, the return pipe is blue. If further laying of a laminate or linoleum is necessary, then the flooring of a small sheet of plywood becomes.

Under the plywood fit the substrate, which compensates for irregularities and is responsible for thermal insulation. The main thing when installing plywood is not to damage the tubes with the sharp ends of the fixing hardware.

The technology of installation of an electric heated floor has its differences, but like a water-heated floor begins with the correct measurements. It is necessary to know that the cable:

- can be laid in a concrete screed;

- can be mounted on top of it. Then you can immediately lay the laminate.

For the operation of an electric floor heating is required to carry out a check of the electrical wiring, if it does not cope - then you need to call in specialists. Do not plug it directly into a power outlet. Electricians recommend removing a separate outlet and installing fuses.

To mount this type of warm floor should be on the prepared surface. If you do not align and eliminate all the protruding and interfering parts,the result will be disastrous. You can do without a cement screed. It is best to use special mixtures, they dry faster.

Quite often, penofol is used as a heat insulation material - a kind of foamed polyethylene film wrapped in foil. Foil is responsible for the reflection of heat. Thanks to the self-adhesive layer to mount a warm floor turns out twice as fast. Insulation is fixed tightly.

When laying the foil should be on top, and the junction is best to glue with adhesive tape - tape. After installation, the room should be glued around the perimeter with edging tape - this compensates for expansion of the floor during operation.

The temperature sensor is installed directly into the corrugation, but it should not rise much above the cable. It is necessary to bend a corrugation carefully, without allowing bends. The end of its “underground” part is treated with a sealant.

Installation of the assembled system is carried out either on mats or on tapes. Mats are finished products that cannot be bent. They are easy to install - by fixing to the insulating material with ordinary tape. The distance between the mats should not exceed 10 cm, and the indentation from the wall should be equal to 20 cm.

On a special tape the cable keeps within a snake. Fixing occurs with plastic clamps.Special attention is paid to observance of the distance between the bends.

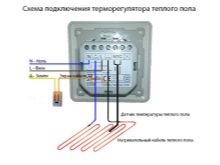

The thermostat is displayed on the wall. All further adjustment will be carried out through this device. Therefore, it is advisable to install it at a convenient distance and in the right place.

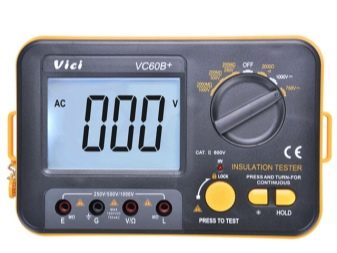

Before making the final casting of the screed, check the performance of the product with special devices - a tester and a megohm meter. Their indicators must comply with accepted standards.

Typical errors when installing an electric floor heating:

- Purchase of unclaimed building materials. If the measurement was carried out total area, but not useful, then there is a purchase of excess. Under the furniture, as a rule, the warm floor does not fit.

- Wire cutting. In no case it is impossible to do this, it is better to leave a small part unheated.

- Inclusion in the network until completely dry. This leads to the formation of cracks on the screed.

- Install the floor on an unprepared surface, which leads to the formation of air bubbles. And they, in turn, may adversely affect the operation of the cable.

How to connect?

Work of a heat-insulated floor is controlled by a temperature regulator.It can be both electronic and mechanical.

The electronic version works on the basis of special software components. It can be a touch type or push button. All data is pre-recorded in the program filling, in contrast to the mechanical type of thermostat.

The thermostat is set at the height of the position of the lowered hand - it's about a little more than a meter from the floor. It should not have direct light sources. Next to it, the location of other heat sources is unacceptable.

Like all electrical devices it works from 220 volts. To connect it to the electrical network requires a separate outlet. Do not neglect the instructions, the manufacturer initially took care of its customers and printed the wiring diagram. The instruction contains the entire sequence of actions.

The thermostat is universal, it can control the operation of the heat mat, the heating cable and the infrared film. Connection of all types of electric floor heating should be carried out in compliance with safety regulations.

If several warm floors are installed in the room, each of them has its own temperature controller.On the one hand, such an action will protect the network from overload, and on the other, it will independently control the temperatures in all rooms. At the same time electricity consumption does not increase significantly.

After all the preparatory moments, the phase is brought to the junction box. Recesses for the tube are made in the wall. In one - the power cable, the other is the wire from the sensor. Do not forget about the grounding and zero. And further it is necessary to connect two component parts of a heat-insulated floor.

When connecting, you must use the instructions. Depending on the heating system, either a single or two-core cable can be used. Therefore, the connection will be different.

Experts recommend wire numberingThis will reduce the time spent on the connection. Wires are connected either by twisting or soldering, but do not forget about the insulating tape.

In urban apartments, water floor heating “did not get accustomed”, and for country cottages, experts recommend connecting it to an individual heating system. Best of all, when switching between boilers is provided for, it ensures uniform operation without drops and failures.

Consider the features of the room

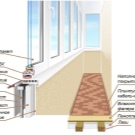

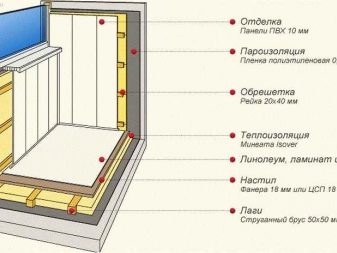

Before you install a floor heating system on the balcony, first of all you need to take care of its glazing. Not every glazing will do. If it is wooden or metal, not only will cold air flow through the gaps, but also to freeze the base itself.

From the point of view of common sense, the glazing should be made of the profile PFH. This modern solution does not let the wind into the room and retains heat inside it.

It should be borne in mind that the more cameras the profile has, the better. Experts recommend ordering at least a three-chamber profile. There is a direct dependence on the number of double-glazed windows, but at the same time, the more of them, the heavier the design itself. In some cases it is more reasonable to reinforce the balcony with a metal frame before the glazing.

But that's not all, before covering the loggia, all the gaps should be sealed with construction foam. You can sheathe any building materials. The most commonly used plastic panels or laminate.

As guides, it is best to use wood, not metal, since the metal in the winter accumulates cold in itself.Sheathing of walls and ceiling should go with the use of insulation. If the financial situation allows, you can also withdraw central heating.

In most cases, mineral wool acts as a heater, but it is not very durable and is afraid of moisture, so there should not be condensation or cracks.

Foamed glass is used less frequently due to its undemocratic value, but it has no other disadvantages.

From polymeric "representatives" you can choose extruded polystyrene foam. This is a modern development, its main task - thermal insulation, it performs perfectly.

But before you have to warm the floor, you must prepare all the necessary materials for the work. This will require:

- Extruded polystyrene foam. The thickness of its sheet should be no more than five centimeters.

- Rolled insulation with foil.

- Special adhesive tape.

- Bricks and special mix.

Bricks may be required in cases where there is a gap between the slab located on the floor and side walls. With their help, the clearance is sealed.

Wall cladding is performed in several steps:

- Guides are mounted on the walls and ceiling, for example, cant used. Then its dimensions should be 50 x 50 mm.

- Insulation is placed in the resulting gaps.

- A special foil is fastened on top of the insulation. Joints can be glued with ordinary adhesive tape - tape.

- By means of the screw gun sheets of gypsum cardboard fasten.

- It is necessary to zashpatlevat seams.

The simplest floor heating system for a loggia is electric. At the same time, for the cable variant, a tie coat is needed, but for the infrared one, no. For the first option further laying tile, and for the second - laminate, linoleum or carpet.

It is necessary to lay a warm floor only on the cleaned surface; to do this, remove garbage and dust. You need to wait until the prepared surface is completely dry.

For the balcony it is preferable to use the heating cable in the mats. If the large rooms have to take into account the location of household appliances and furniture, then on the balcony you do not need to do this. For fixing the cable used mounting tape.

With cable versions of a heated floor to make a coupler.Laying mats more practical in length, retreating from the wall about five centimeters. After that, it is necessary to mount a thermal sensor and place a corrugated tube in the wall.

Further work is described in previous sections.

Installation of infrared floor heating is much easier than cable. But it is worth remembering that the end of the corrugated tube should be located strictly between the heating parts.

By the way, in the apartment you can install heating systems for floors in any room - in the hallway, in the bathroom, and in the kitchen. The main thing with this consider the footage, so as not to spend money on extra supplies.

Quite another difficulty may be faced by owners of suburban square meters. For example, owners of summer and garden plots often receive water on certain days and hours, and they turn off electricity in the first days of October. And from this it follows that the country will have to carry alternative energy sources - generators.

Technology installation of a heated floor in a wooden house depends on the characteristics of the overlap of the first floor and basement. If concrete slabs were used, then the process is similar to that described earlier.

But in old wooden houses, as a rule, use ordinary timber and planks. Therefore, you need to implement:

- Nailing to the beams of the additional base and gratings from the timber. This will be required for further laying of insulation - mineral wool or synthetic foam.

- On top of the insulation lay aluminum foil, it reflects the heat.

- Mount the floor heating system according to the instructions.

- Check its performance.

- Lay a suitable class laminate.

In modern water-heated floors, metal plates are used for thermal distribution. They not only reflect the heat, but also form channels for the tubular system.

To simplify installation, you can purchase ready-made chipboard plates. The factories are specially made excavations for laying water floor heating. Or use the foam pad - its design is also suitable for this task.

Unfortunately, they are very expensive and not everyone can afford. At home, you can fill the bar yourself, it will take extra time, but the result will be the same.

Additional insulation

Thermal insulation when laying a heated floor is needed so that during the operation there are no situationsin which warm air "volatilized." Everything else, the insulating layer acts as a substrate. On it are laid the wires or tubes, depending on the types of warm floor.

There are a number of requirements for the insulation layer for an electric floor heating. Firstly, it should have a small coefficient of thermal conductivity, and secondly, resistance to high temperature indices.

Ease of stacking and resistance to deformation - are also key points. By the way, insulation in addition to functional features levels the surface.

It should be added that the heat-insulating layer must withstand heavy furniture and large household appliances, not to let out noise, be made of environmentally friendly materials. Be immune to moisture and microorganisms.

Not the last role plays electrical safety of the productYou should not buy it in questionable outlets. The service life at the same time the higher - the better.

Thermal insulation is made from natural raw materials and synthetic. The bark of cork oak belongs to the natural one, and polypropylene, penofol and folgoizolone belong to synthetics.

Cork insulation is made from the bark of cork oak. The stores found meter width. Rolls reach ten meters. This insulation does not need to stick, just enough to lay.

It has high noise absorbing properties. If the manufacturer has added a rubber base - waterproofing is not necessary. Unfortunately, cork insulation does not have heat reflectors, they should be installed additionally. Artificial insulation, made on the basis of porous polypropylene, may contain markup. When available, the installation process is simplified.

A conventional aluminum foil acts as a heat sink, it contributes to an increase in heat efficiency of more than fifty percent.

Penofol is made from polyethylene foam, has a foil layer and has four classes of varieties.

Class A is equipped with a heat-insulating foil layer on one side only, and class B - with two. In the third class, the second layer is not made of foil, it is - adhesive, in the latter - the adhesive layer is replaced with a film of polyethylene.

Sewn folgoizolon has an increased service life, in contrast to the unstitched.For cold rooms, such as a balcony and a bathroom, this option is the ideal solution. Therefore, experts recommend installing a heated floor with this heater, not forgetting to warm the loggia itself, otherwise the effect will be zero.

Additional insulation can be a special laminated film made of polyethylene and having a markup for a warm floor.

The maximum temperature of a warm floor is possible only when using high-quality insulation. It is especially important to put it right. The seams and joints are glued with foil tape, and the gaps between the floor and the wall are taped.

It is worth remembering that high-quality heating means laying the insulation layer on the walls. The height should not exceed 20 cm.

For water heated floor is recommended to use penoplex. Penoplex is an extruded polystyrene foam, it is in fact a durable polystyrene, manufactured using special technologies, thanks to which it does not absorb moisture.

This material has a small coefficient of thermal conductivity, prevents the formation of fungi and microorganisms, and therefore is a safe material.And he maintains heavy furniture and large household appliances and is easily cut.

Due to the heater, not the lower part is heated, but the upper part. Ponoplex can be laid without the use of concrete screed, so this insulation can be used in private homes.

Reviews and Ratings

Before buying a warm floor, it is very important to read consumer reviews and study the rating of the best manufacturers. In most cases, the first lines will match:

- Danish company ranked first in the rating of electric underfloor heating Devi. The manufacturer gives a guarantee for its products for a period of twenty years. Buyers of the products of this company confirm that in the concrete screed cable underfloor heating has been operating for the second decade without any failures. Air drying does not occur. And what is most interesting, having excellent quality, the products of this company are sold at an attractive price.

Service centers are located in all major cities, and from this it follows that even if something becomes unusable, the product can always be repaired or exchanged under warranty.

- The second line in the ranking is the South Korean company Caleo. She gained her fame thanks to infrared warm floors. This is a high-quality, but very fragile material, its thickness is less than half a millimeter. Laying it under the laminate need to be very careful. The price is slightly higher than the products of the leader of the rating, but this is a novelty in the construction market.

- Russian manufacturer "Heatlux" located in third place. Today, products are exported to a dozen countries, and in great demand in the domestic market. Excellent value for money.

- Another quality manufacturer is considered to be firm Ensto. She comes from Finland. The engineers of this company made the main bias on wet, dry and unheated premises. Warm floor of this company can be laid even under the stone. The price range will please representatives of the premium segment, and people with small earnings.

- Vplan economy stands out manufacturer from the UK - Energy. This quality applies to the cost of the finished solution, and to low power consumption. In this case, the price at an affordable level and a large selection of different offers. Not the last role in the assessment has played a bet on environmental safety.

- Another representative of South Korea is the manufacturer Unimat. Their infrared warm floors are installed even in baths and saunas. As you know, carbon rods do not deteriorate under the influence of moisture. The warranty period for the floors of this manufacturer is twenty years.

- German manufacturer Rehau is the last participant in the rating of electric floors. Its products are easy to install, has excellent quality and affordable price. By the way, this manufacturer, known since 1948, produces plastic windows, and water heated floors. In the ranking of manufacturers of water floors, it occupies the first line.

- The next position is the Italian company Sanext. This manufacturer has representatives in the domestic market, produces all components for water-heated floors. The company focuses on the production of cross-linked polyethylene pipes. According to customer reviews, the warm floor of this company will easily serve for ten years.

- German manufacturer Aquatherm another leader in this segment. Has been producing its products for over forty years. The company is a patented manufacturer of plastic pipes.For ten years, the manufacturer guarantees the smooth operation of their products.

- High quality and durability and have warm floors from the Finnish company. Uponor. For more than half a century of experience, the manufacturer has gained tremendous knowledge in the field of water-heated floors. Among the owners of suburban real estate products of this company is popular in Russia and in the world.

- Italian company Emmeti, Belgian Henco induscties and German manufacturer Oventrop occupy the following lines in the ranking. These manufacturers have been known on the market for more than a decade. One of the best not only in Europe, but also in North America, and in Australia.

- Of the young representatives stand out: the company Kermi from Germany, Finnish Purmo and swedish Thermotech. They produce components for water heated floors, showers, offer a range of services.

- From domestic manufacturers can be identified a joint venture of Italy and Russia - Valtec. European standards are observed in production, the best technologies are used. The company won the Brand of the Year nomination several years ago. Great combination of price and quality.

- "Special systems and technologies" known on the Russian market for more than two decades. Exports of products are established in forty countries. Tight quality control and thoughtful logistics have allowed this company to take its rightful place in the construction market.

- Last place in the rating given to the company Compipe. Its plants were built not only in Europe, but also in Russia. Full production of components, affordable price and availability of products made this company a leader.

Successful examples and options

In conclusion, I would like to note that modern underfloor heating can be laid, including under the laminate. High quality laminate does not deteriorate. Installation of a warm floor of a new generation can be performed by any adult, since it is no longer necessary to make a concrete screed. This section presents photos of the most successful examples and options.

In the next video you will find a detailed workshop on the installation of film warm floor.