Methods for laying the substrate under the laminate

Laminate - is one of the most popular finishing materials, which is used today in the arrangement of the floor. A feature of the installation of this product is that it should be laid on a perfectly flat base. Solve this problem with a special substrate, located between the laminate and the floor surface. To create a solid base that will extend the life of a decorative coating, it is necessary to study all the ways of laying this intermediate layer.

Purpose

The substrate under the laminate is a material that has a low density. The main purpose of this substance is smoothing the surface. This is necessary when the floor level has small drops.In this way, you can create an optimal base under the laminate, which does not tolerate strong bends.

It should be noted that the substrate is able to even out small drops.

Therefore, the preparation of the base for this material should still be carried out. If this is not done, the boards can quickly fail, even if you use a thick backing.

There are several other tasks that can be solved using this product:

- Noise isolation. Some types of materials can perfectly absorb sounds. Moving around the laminate with the substrate will be pleasant, even if you walk in heels.

- Moisture insulation. Substrates are made from such substances, which also perfectly retain moisture. This allows you to exclude its effect on the laminate, which is simply pasted in water. The best option would be to use a plastic film that is completely hygroscopic.

- Thermal insulation. Creating an optimal microclimate inside the room is one of the tasks of the flooring. Very well deal with this substrate, which do not let the cold from the inside to the laminate. Therefore, the board has an air temperature in the room, but at the same time it itself has poor thermal insulation parameters.

Kinds

The substrate is a roll material of natural or artificial components. Today there are several types of similar products, among which there are several main products:

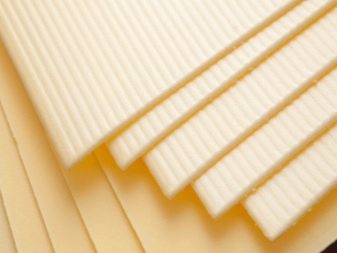

- PE foam. The substrate of it is the most common and affordable, as it has a low cost. The substance differs quite good indicators of moisture resistance, heat insulation. The corrugated surface of the material is not damaged by rodents and microorganisms, which allows to extend the life of the floor. Today, foil-coated polyethylene, which reflects heat better, is particularly popular. But this substance is very bad shape and sags over time, which affects the laminate.

- Bung. Substrates of this type are made from natural substances. Cork products also do not rot and are not affected by mold. Moreover, the material retains heat very well, which makes it one of the most popular. Both rolled and leaf varieties of this substrate are on the market.

- Bitumen-cork substances. The substrates of them are made of cork and kraft paper, which contains bitumen.The cost of such products is very high, so it is used only for expensive types of flooring.

There are also combined types of substrates that combine several substances. This allows you to improve the technical characteristics of the material:

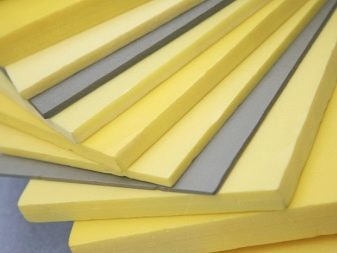

- Styrofoam. The material perfectly aligns the surface of the floor, and also qualitatively retains heat. Substrates from it also do not let in sounds and moisture.

- Coniferous tiles. This type of substrate is made of natural wood, which makes it completely safe for humans. The disadvantages of this material is the high cost and relatively low density, which is significantly lower than that of cork.

Which is better to put?

The choice of substrate depends on several main factors that are important to pay attention to:

- The quality of the floor. If the surface is not very well aligned, then you will have to use expanded polystyrene or cork of considerable thickness. In the other case, you can get by with a thin layer of polyethylene foam.

- Microclimate. If moisture builds up on the floor, then it is important to take care of its insulation.To do this, combine polyethylene films with other types of substrates. An alternative can provide polystyrene foam, which does not pass moisture.

- Technical specifications. It is important when choosing to consider whether the substrate can not only level the surface, but also to provide the desired level of sound or heat insulation. This factor is important if the installation of the floor is done on the first floor of a private house or apartment of a high-rise building.

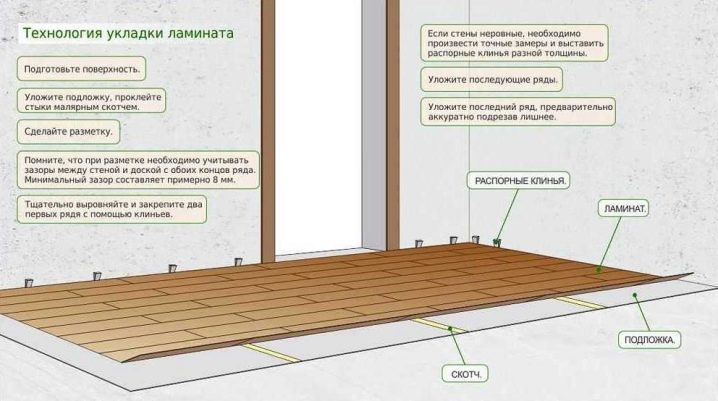

How to lay?

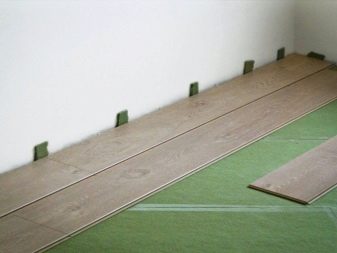

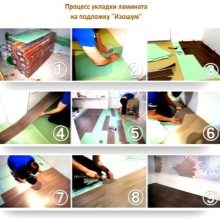

The technology of laying the substrate under the laminate involves not only its fixation to the surface, but also high-quality floor preparation. Therefore, it is desirable to perform all the procedures in the complex, as this will facilitate the process and prolong the operation of the laminate. Laying the substrate is desirable Only on a clean and level surface.

Therefore, before you put your own hands, it is desirable to vacuum the floor and remove sharp objects.

Materials and tools

Installation of the substrate begins with the acquisition of the necessary material, as well as the search tool. For such works you will need a set of such items:

- Substrate. Its quantity is calculated depending on the area of the room and the width of the roll material or one sheet.It is advisable to take products with a small margin to eliminate the shortage in case of incorrect measurements.

- Scotch. It is needed to bond the substrate pieces to each other. This will not allow it to move on the floor, as it must lie flat and without tubercles.

- Roulette.

- Knife and square. The last element will allow you to get an even cut of the material at a right angle.

How to level the floor?

The coating under the laminate should be of the highest quality. Therefore, it is important that before laying the substrate, take care of the field itself. Depending on the type of floor, its alignment may occur in different ways. The process of preparing a wooden floor can be performed using the following approaches:

- Dry screed. This method involves the formation of a concrete layer on wood. Before this, it is important to lay a waterproofing film to prevent solution from getting onto the wood. It is used quite rarely, as it is labor-intensive and long.

- Alignment using sheets. For such purposes, use plywood, OSB or drywall. Installation of sheets is carried out directly on the old floor with screws or glue.Here it is important only to form a flat surface with minimal differences.

- Scraping This process involves the removal of the top layer of wood using special machines. It is carried out only for wooden floors of considerable thickness and durability.

Preparation of a wooden floor also implies a preliminary assessment of its strength. If rotten boards are present here, it is desirable to replace them with new ones.

Leveling a concrete floor can also be done in several ways:

- Grinding. This process involves the removal of concrete in certain areas of the room in order to align the entire plane. Use it only if the surface has minimal differences.

- Adjustment by cement. This approach is also used for small irregularities. A self-leveling mixture is applied to the surface of the concrete with a thin layer. After its solidification forms a flat plane.

- Full screed. The algorithm involves laying beacons strictly horizontally across the room. Then the entire surface is poured with a thick layer of liquid concrete and carefully leveled relative to the marks.

Is it possible to lay two substrates?

Today, many people plan to use two layers of substrate for laying laminate. They think that this will significantly improve the heat and sound insulation of the floor. According to the recommendations of specialists, a film of polyethylene can be laid as a second layer, which will protect the laminate from moisture. The installation of two conventional substrates will result in the surface will become too soft. Over time, the laminate locks on this basis will simply break and the boards will begin to hang in the air.

Therefore it is better to use only one layer of material with high density and small thickness.

Which side to put?

The substrate is made from various substances, but often its external structure is not different. Manufacturers produce rolls in which one side is smooth, and the second with small protuberances or grooved. Substrate mounting should be done in such a way that its smooth side faces outwards.

If you are using foil products, then this layer also needs to be placed to the top. This will allow him to beat off the heat, which will try to go through the floor.

What can be glued together?

Installation of the substrate is performed on an even and dry base, so the attachment of the material to the base is not necessary. Please note that the sheets must not be fixed, therefore no glue is used. Experts recommend sticking together only joints with scotch tape. This will allow you to get a flat and solid surface that will not move during the laying of the laminate.

Professional Tips

Substrate mounting is an important process on which the state of the entire system depends. To eliminate installation errors, Experts recommend following a few simple rules:

- As a substrate, use dense materials whose thickness does not exceed 2 mm.

- If the floor is very uneven, do not try to level it with a layer. It is necessary to perform the preparation of the base before laying the substrate.

- When laying sheets of a substrate connect only in a joint. Do not put material on each other, as this will lead to the formation of unevenness, which adversely affects the laminate.

- The substrate is located tightly to the walls. Any gaps are excluded between the material and the vertical supports.

- If substances from wood fibers are used, they should be laid at an angle of 45 degrees relative to the walls. As for the roll materials, their direction is chosen individually. Some experts argue that the sheets should be perpendicular to the laminate boards. But it is not so important if the installation is done with high quality.

Laying the substrate is a simple operation that requires only care and accuracy.

If you are doing this for the first time, you should always consult with experts to get an even and strong base for the laminate.

How to choose a substrate for laminate, see the following video.