Types of laminate locks

In the modern world, laminate flooring is popular. A special system of laying laminated panels, which locks them together with a lock, allows you to update the floor easily and quickly.

The service life of the flooring depends on the quality of locks and compliance with the technology of laying panels.

Special features

The technology of locking the laminate was developed not so long ago, but has already managed to earn the love and recognition of people involved in the repair. There are several reasons for this:

- Laminate locks facilitate the process of laying the floor covering. For laying no need for additional fasteners or glue. The snap-in device is already mounted in the panel.

- If the panel is damaged, you can easily replace the broken part. This increases the lifetime of the laminate.

- The locking system of fastening laminate panels allows you to lay the most accurate floor covering without protruding or indented areas.

- The sides have a special shape, which, when snapped into place, connect panels without gaps and do not let moisture through. This reduces the likelihood of mold under the floor covering.

Variants and description

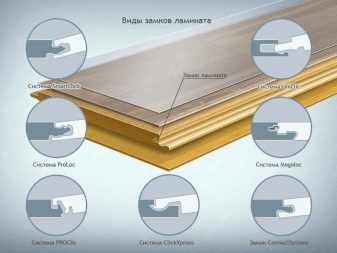

Although many firms in advertising companies use the patented names of the fastening system for laminate panels, there are only two types of these locks. The remaining varieties are prototypes of one of these two species, equipped with modifications or modifications.

First, consider the basic types of locks:

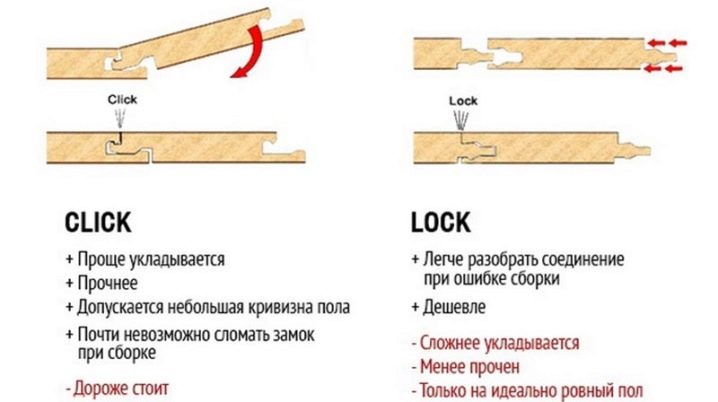

- Locke Locks appeared much earlier than another type and are considered more budget. This mechanism works according to the “thorn-groove” principle, that is, on the one hand the laminate board is equipped with a tongue with a comb for fixing, and on the other hand it is a groove. The installation of the lamellae with the Lock system is carried out by driving the spike into the slot cavity with the help of a wooden mallet or hammer with a rubber head to complete the connection. Unfortunately, during operation from the load on the panels wear of the dies occurs, therefore gaps can form in the floor covering.

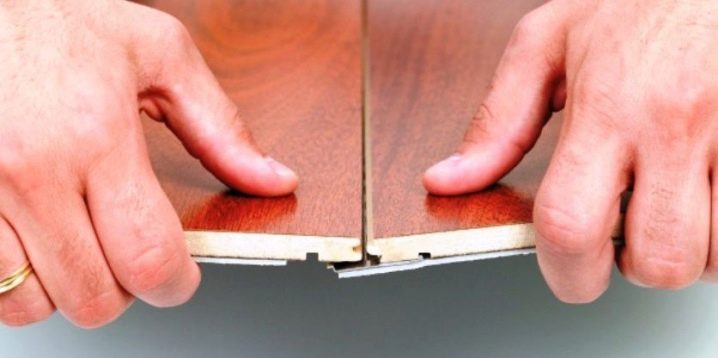

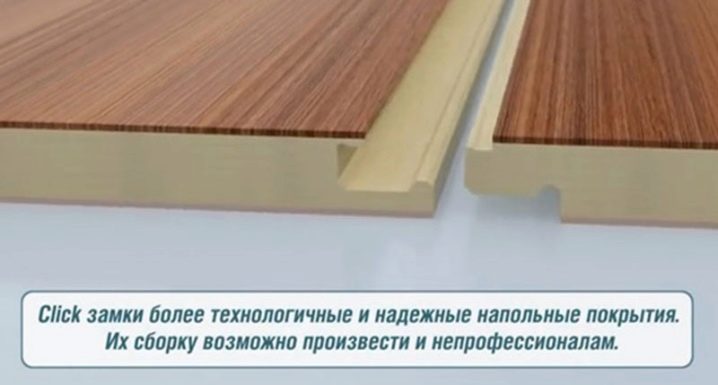

- Click locks, which are also used to connect the lamellae are considered more modern and are made with regard to past errors. The name of the Click locks comes from the characteristic click that is usually heard when the panels are closed. The production technology of panels with click-lock is similar to the previous view. However, the side with a spike is in the form of a hook, and the groove cavity is arranged in such a way as to hook this hook. Assembling the flooring with such a fastening system does not require much effort and is done fairly quickly. To do this, the panel side with a hook lead to the other with a groove at an angle of 45 °. Then the panel should be lowered. Then there will be a click indicating the spike is in the groove.

In contrast to the Locke system, click-locks are not afraid of heavy loads, and are also easy to disassemble.

In addition to the basic locks, many companies, using their own technology, produce laminate with patented locks. Among the existing proprietary developments can be identified:

- Just click from the Austrian company Egger can be called a classic example of locks with a click system. The panels are closed at an angle from 30 ° to 45 ° around the perimeter, due to the high spike obtained dense joints, which makes the laminate resistant to serious loads.Some Egger lamella models with a justcastle system come with a special Silenzio underlay that helps make the sound of the steps softer.

- Uniclic is an accomplishment of Quick Step from Belgium. The peculiarity is that it can be latched both under the slope, and with the attachment and even tamping of the slats. Such a variety will suit inexperienced users. Laminate with the system Uniclick is perfect for finishing the floor in rooms with irregular shape, various obstacles and hard-to-reach places - a multi-level floor or a low-lying battery.

- ProLoc and SmartLock are the developments of the Belgian company Prego. The first type is represented by a fastener system of three components, which increases the resistance of the laminate to high loads and allows you to repeatedly disassemble and assemble the floor covering. The second type refers to simpler fastening systems that are easily mounted at any angle and easily transfer loads.

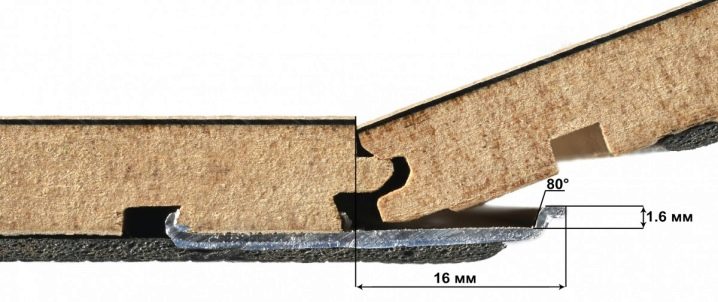

- Another company Berry alloc manufactures its products in Belgium and Norway, with Norwegian laminate being manufactured with aluminum locks. The patented names of the lock connections of this company are of two types - 4G and 5G-S Aluminum Locking System.These locks successfully combined all the best qualities of the two main types of locks, and the metal spike and groove system increases the fastening strength and makes the installation process faster.

Aluminum locks allow you to use laminate in places with high load and high intensity of foot traffic. According to the manufacturer, the panels can be disassembled 3 times and reassembled without losing the quality of the floor covering.

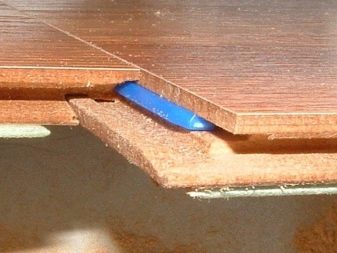

- Also found locks 5G with a plastic insert that resembles a tongue. A distinctive feature of this type of lock is the assembly of the panels in a horizontal position, which allows laying even the beginner to cover.

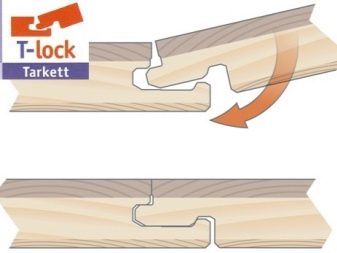

- Latching system for laminated panels T-lock is a development company Tarkett. This kind of locks allows the spike to snap into the groove of the other panel at an angle of 45 °, not only along the length of the laminate, but also from its end side. Such a system is distinguished by its reliability and strong connection. Laminate with double clutch is able to withstand considerable loads and last for a long time. During operation, T-Lock is not erased, does not break and does not diverge.

- Another popular lamella lock Clickxpress equipped with a rounded bottom from the side of the spike and groove, plastic parts in the model are missing. The ability to assemble and disassemble such a coating comes up to 4 times.

Which is better?

A person who is not professionally engaged in repair work, it is quite difficult to choose a suitable laminate among a variety of lock joints.

According to most experts, the most practical design is the floor covering with Click-locks. And although the locks Lock over time less susceptible to stretching and easier to understand if necessary, and the price of such a laminate is more democratic, yet they are more outdated modification. Over time and under heavy loads joints at the joints wear out, forming gaps between the panels.

The Click system, in turn, guarantees maximum durability of joints with repeated assembly and disassembly and without damaging the locking system. Laying such a coating is very simple and fast, even on the floor with minor irregularities.

And although for such a laminate will have to pay more money, but the quality of the coating will remain at the height of more than one year.

How to connect?

The method of laying laminated panels and their connection to each other depends on the type of laminate. Before laying the lamella in any case need to eliminate the differential and unevenness of the floor using a screed, and then lay the substrate.

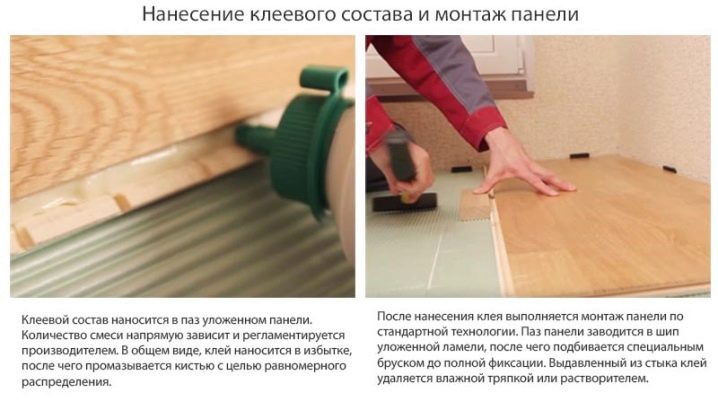

There are two options for connecting panels when installing laminate. The adhesive method due to a special technology protects the joints between the panels from moisture penetration. Therefore, the lifetime of the floor covering is significantly increased. But it has this method and a lot of negative points. For example, the expenditure of additional funds for the purchase of a special anhydrous adhesive composition, besides, gluing laminate is always more difficult and longer. Heated floor is absolutely incompatible with the adhesive method of laying laminate.

In order to lay the laminate in this way, it is necessary to apply glue to the slot part of the panel and insert a spike into it. Then, using a wooden head hammer, you need to squeeze the slats as tightly as possible. Excess adhesive must be removed with a cloth. First you need to lay out three rows of lamellae and wait a few hours until the glue is taken.Then you can fill the rest of the room with lamellae.

Before complete drying of the floor should take at least half a day.

However, due to ease of installation, construction stores are increasingly offering laminated panels with different locks. Laminate assembly with lock-locks occurs by hammering one panel into another. Most Click-mechanisms are connected at an angle, and when the panel is lowered to the floor, the lock is closed. If necessary, the panel can also be routed with a hammer.

A laminate with a lock joint has approximately the same assembly algorithm. Before laying it is necessary to measure the width of the room so that for the last row there is at least 5 cm in length. If necessary, shorten the lamella of the first row. In addition, you need to leave gaps for thermal expansion.

When laying the panels in an adhesive way or using lock-locks, you need to dock the panels first along the length and then along the front side. For Click-locks, typing the entire row of lamellae at once and attaching it to the previous row with a whole canvas is typical.

Therefore, for a large area of the room is better to enlist the support of an assistant.

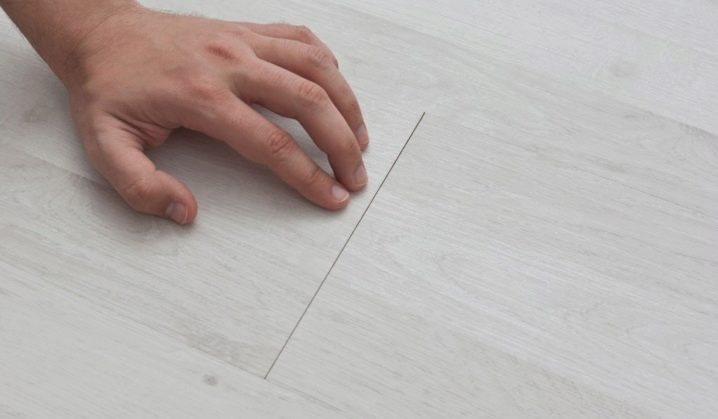

Why does it diverge?

Sometimes even such a flawless flooring, like laminate, can break up. Then it is necessary to determine the cause of damage to the coating and, if possible, eliminate it.

The reason for the failure of the laminate may be dry air due to which the panels shrink and crack. To avoid this, you need to constantly ventilate the room, or install a humidifier.

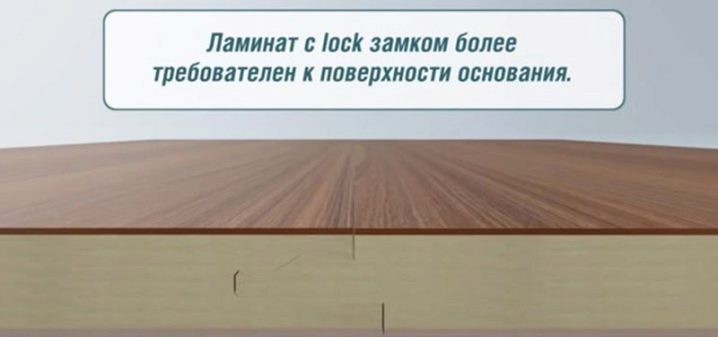

Neglect of the screed before laying the laminate leads to the fact that the laminate on an uneven floor disperses, creaks or sways when walking on it, and the locks become unusable.

If the panel lock broke very quickly, then this may be due to the poor quality of the goods. No need to chase the cheap and choose models of unknown manufacturers.

Failure to follow the styling technology laminate flooring also often leads to problems with coating. Often during installation they forget to leave gaps, and when the boards swell, the laminate will crack. Do not forget to remove debris from the floor, because even a small stone can disrupt the work of the highest quality castle.

What to process from moisture?

Impregnation of laminated panels is an integral part of the floor installation process. Moisture protection not only provides additional protection against moisture, but also facilitates the installation process. In addition, locks impregnated on both sides exclude the appearance of squeaking floors. It is possible to meet on sale both the panels processed by means, and those that need to be greased independently. Previously, repairmen used paraffin candles for this, today there are special wax crayons.

Processing is done after laying the laminate. For this there is a mastic and other substances based on paraffin or polyurethane. These tools protect the seams from dirt and moisture, and also give the boards an extra shine.

Wax mixtures should be used only in the area of the joints, since stains may remain on the panels.

Successful examples and options

Castle laminate in the kitchen will be a practical and durable solution, besides adding a presentable interior.

For a studio apartment as a single flooring, you can choose a neutral tone of the slats.

Light gray panels, treated with a moisture-proof composition, quite well fit into the interior of a spacious bathroom with a window.

For more information on this issue, you can find in the next video.