Vinyl laminate: advantages and disadvantages

Vinyl laminate is a modern analogue of polyvinyl chloride tile. Improved physical properties and decorative qualities make this material practical, versatile and stylish, which explains its growing popularity.

What it is?

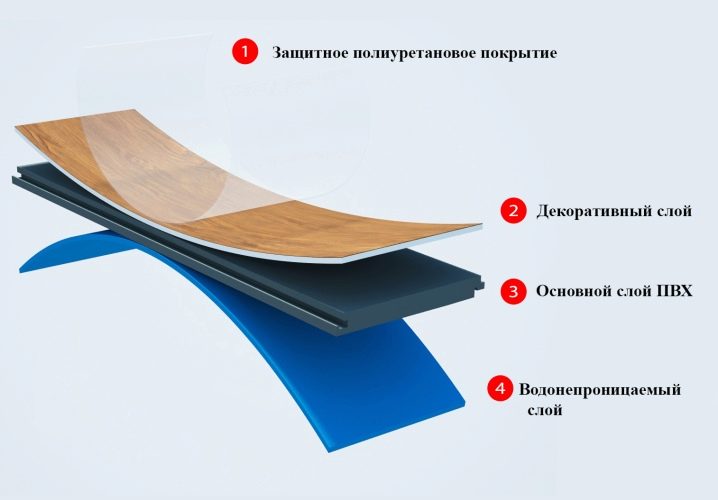

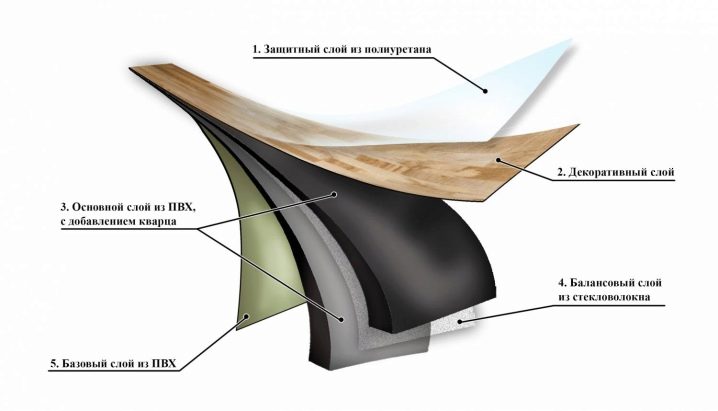

Its structure is multi-layered. The basis is polyvinyl chloride with additives (as a rule, these are quartz sand additives - about 80%), which provide good rigidity, flexibility, as well as resistance to deformation and moisture. The top and bottom of the product form PVC layers with fiberglass reinforcement. Then follows the base, reinforcing and soundproofing layer. On top is a patterned layer, protected by a polyurethane coating.

Features: pros and cons

Material advantages:

- moisture resistant and hygienic.It washes well, does not swell and does not slip. Thanks to these qualities, gained popularity in the repairs in the kitchens and bathrooms;

- wear-resistant and durable;

- not difficult to install. In most cases, you can cope with the installation yourself, since it is possible to lay on top of the old coating;

- easy to clean;

- safe;

- durable;

- has excellent thermal insulation and sound insulation properties;

- diverse in design. You can imitate the color of different types of wood or stone;

- used with warm floors. The maximum permissible heating temperature is 300 ° C;

- able to protect glass objects from breaking when dropped;

- fireproof and does not support burning process.

Disadvantages:

- susceptible to solvents. Prone to discoloration when touching rubber products (excludes the use of rubber mats);

- hot objects damage the product;

- fades and deforms with prolonged and direct exposure to sunlight;

- increased cost of quality products;

- low maintainability when laying on glue;

- when burning emits harmful substances.

In addition, chemical additives are used in the production of these coatings, which, after installation, can cause temporary toxic fumes. In the environment, the material is not destroyed, it is not recycled. Sharp objects that fall on its surface leave a mark on it.

Other features that are important to consider when installing laminate:

- The technology of mounting on glue is quite complicated.

- The use of locking quartz vinyl laminate makes it possible to perform all installation work much easier and in a shorter time.

- Panels with a layer of glue are easily laid on top of the old coating.

- Tile with adhesive tape has a locking device around the perimeter, and snapping is done here with the help of a fixing composition.

Species

Strictly speaking, polyvinyl chloride (PVC) or PVC sheet plastic is one of the types of plastic products developed in 1835. The full name is thermoplastic plastic. Vinyl is the main strength component of this product; it is this material that covers the basis for increasing its strength. In this case, the strap itself is a two-layer product.The first layer of polyurethane, in addition to strength, gives the canvas the appearance of wood, parquet or stone (variants of leather and sand are possible).

The product is divided into 2 types: according to its composition and the method of flooring. It is installed with glue or locking system.

In composition:

- Usual;

- Contesse;

- Quartzvinyl.

The first option has a two-layer structure (with a PVC layer), with different colors.

Contesse is the same ordinary laminate, but supplemented with a whole range of other qualities that make it more popular. It is practically unaffected by chemical reagents and can be treated with disinfectants. Its structure contributes to greater strength, it is not amenable to the action of ultraviolet rays and is fireproof.

The quartzvinyl version of the laminate includes a fine fraction of ceramic granite. Belongs to extremely durable materials. It has antibacterial properties, suppresses unpleasant odors and deodorizes the indoor environment, and therefore is used in medical organizations.

In the Russian market vinyl laminate is sold in the following varieties:

- Cloths 43 class, castle type - high-strength and easy to install.

- Self-adhesive coatings are the easiest and easiest to install.

- Moisture resistant variants of Ecoclick series laminates.

- Vinyl laminates with adhesive backing (self-adhesive).

- Vinyl products under the tile.

Vinyl tiles are produced in two versions: flexible and rigid. The peculiarity of the first is that it is easily mounted on a surface with irregularities, the second - from irregularities is deformed.

Also available:

- Vinyl parquets, which are in great demand because they perfectly imitate wooden parquets. Available in the form of square tiles. Such a parquet is durable, easy to install, environmentally friendly.

- PVC tile. It is used under the shades of natural stone or ceramic tile. High strength and resistant to chemical reagents.

- Sheet coating. Available in the form of rectangular plates with imitation wood. Complemented with a felt backing for extra softness.

Specifications

The standard dimensions of coatings are about 10x92 cm, or 18x92 cm. It is planned to produce floor laminate with a thickness of 6-14 mm. At the same time, products with a thickness of 10 mm and more are already thickened and, along with increased strength characteristics, have an increased price.

The square tile is produced with a side of 300-600 mm.Thickness is usually from 1.5 to 5 mm, with an insignificant rate of forcing (within 0.08 mm).

Pro strength, degree of deformation and purpose of laminate vinyl divided into 3 classes:

- Household products, 23rd and 31st grades of wear resistance (durability 5-6 years).

- Semi-commercial and commercial types (34-42 class), they are equipped with office, office and crowded premises. According to their properties, they are more durable (last up to 15 years), practical and stylish in various interiors.

- Specialist. cover 43rd class, possessing very high strength properties, are used, for example, in gyms. So, vinyl laminate of this class with a locking device is an extremely durable coating, besides, it does not require special installation. tools.

The first digit of the marking indicates the category of premises for which coverage is applied: 2 - apartments, 3 - public buildings, 4 - production. The second - reflects the level of permissible load, from 1 to 3, and sometimes to 4.

The protective layer of the laminate is usually up to 60% of the total value of the product. Its thickness is in the range of 0.1-0.5 mm. When the thickness of the layer is 0.5 mm, the product is used in rooms with intensive visits to people.

The most common material for the execution of the protective layer is polyurethane with the addition of corundum (4th generation) or with a crumb of ceramics and a component (UV) - 5th generation, which has the best strength parameters.

From contraindications it is important to remember that direct sunlight can lead to fading of the floor from vinyl: with long use it turns yellow

Which is better?

Vinyl laminate is universal, and therefore the best way to use it depends on what you want to use it - for the floor in the bathroom or in the kitchen, on the balcony or in the living room, or for sticking to the wall.

In each case, the choice of the optimal option is possible:

- For the bathroom and kitchen laminate of vinyl must combine high levels of protection against the aggressive effects of moisture and temperature extremes.

- For bathrooms, a solution with conventional vinyl tiles would be preferable. Glue in these cases, use antifungal, waterproof. Tile with an adhesive layer for these rooms is undesirable because it does not withstand excessive moisture.

- For the kitchen is better to use self-adhesive tiles. This type is easy to maintain, waterproof, resistant to abrasion.

- The best option for living rooms is the castle version of the vinyl laminate. The material is stable, reliable, aesthetic and easy to install.

The substrate plays a special role and functionally increases the life of the laminate:

- Depreciation (prevents the formation of cracks in the case of local effects on the surface).

- Keeps from damp.

- Provides protection against fungus.

- Provides noise and thermal insulation.

Substrates are made from both natural materials (cork) and from artificial materials (polypropylene).

How to choose?

Vinyl laminate, which is, in fact, a hybrid of ordinary laminate (not to be confused with fiberglass laminate) and linoleum, has the following selection criteria:

- The functionality of the room and the frequency of its visits.

- Interior space and style.

- Marking

- Structure and shade.

- Installation procedure

- Security.

- Manufacturer, price.

For different types of coatings provides its own way of laying:

- Products with a self-adhesive layer (samokley). Stacked on smooth and clean surfaces.

- Vinyl coatings use special glue.

- Coating with a castle connection.

To protect your health (especially during laying in the bedroom, nursery and kitchen), you should follow a number of rules:

- Acquire products of well-known manufacturers, who value their reputation.

- Check the certificate of conformity for products.

- Take into account the fire safety class of the product. It is necessary to refuse products with a sharp chemical smell. A harsh toxic odor may indicate the presence of prohibited additives in products.

- The best choice is a product, in the marking of which there is an image of a green leaflet - a sign of environmental safety.

Production

In terms of quality indicators and decorative features, the domestic consumer identifies the following 8 manufacturers of vinyl laminate:

- Tarkett and Allure - leaders in the Russian market, and produce products for export.

- Belgian quartzvinyl laminate Finefloor (official distributors in St. Petersburg, Kirov and others) - high-strength and high-quality industrial products, which can be used for household purposes.

- Vinilam - a wide range of moisture resistant products.

- Holzplast - A good combination of quality and price.

- Grunde - products are resistant to moisture and ultraviolet.

- Flexo - represents the variety of shapes, types and designs.

- Moduleo - products with connections like "lock" (Belgium).

Reviews

Judging by the numerous consumer feedback, vinyl laminate, as a relatively new finishing material, receives many positive customer ratings. Their opinions, in particular, indicate that it is difficult to distinguish it from the parquet. Others are encouraged to acquire the fact that this coating (unlike other traditional ones) is practical - it is well washed and not deformed. Marked strength and durability of this product, as well as its practicality.

The consumer is also pleased with the remarkable design of vinyl laminate and the variety of color shades. The only negative aspect was the question of cost.

Large and proven manufacturers in the list below are in descending consumer rating:

- Allure Floor - the high-quality American patented technology. In our market is sold at high prices.

- Quick step - a company from Belgium, specializing in flooring only.Delivers to the market certified products under the brand Livyn - the highest quality products with affordable prices. Constant promotional offers give you the opportunity to save.

- Tarkett - the largest manufacturer. Recently I supplemented my assortment with floor coverings of the Art Vinyl series, produced in the form of slats and tiles of various sizes. The material is characterized by the quality and variety of designs. The company has two factories in Russia, which ensured a low level of prices for goods. An inexpensive brand Polystyl has been created for the Russian market.

- IVC - Belgian company that manufactures products with the brand Moduleo (castle versions) of 32 and 42 classes (service life up to 20 years). Prices are affordable.

- Vinilam - Belgian company. Production satisfies practically any inquiries of the consumer. Prices are average with good quality.

- Haro - products of Hamberger Flooring from Germany. The manufacturer applies its innovative developments, allowing to significantly increase the durability of products, while maintaining their environmental friendliness. The range uses only basic shades. The price is high.

Successful examples and options

Quartz tiles in the living room interior.

Vinyl tiles in the kitchen.Very practical and attractive option.

Quartzvinyl tile Ecoclick in the interior of the living room, designed in a modern style.

Moisture-resistant vinyl laminate AquaFloor in the interior.

For information on how to lay Vinilam vinyl laminate, see the next video.