Non-slip steps from liquid wood: characteristics and features of the WPC

Before you engage in refining the terraces, everyone will certainly think about the materials that will be used. The first in the list is most often the tree. However, in addition to a number of advantages, it also has disadvantages: poor moisture resistance, susceptibility to the formation of fungus and mold, as well as an increased risk of fire. Of course, there are many different chemical materials for wood processing, but they should be updated periodically. Modern technologies today allow the use of materials that have almost no flaws. These products include the so-called wood composite. Most often in the market it is found under the abbreviation KDP.

Woody composite: what is it?

WPC boards are very popular in the market, as they are easy to install, quite practical, convenient to clean, fit well into any design, and also have a reasonable price.

Such a product is the result of an improved technology for the production of materials by the wood shaving method. WPC has a complex structure with a connecting element - polyvinyl chloride. Fillers can serve a variety of materials. The highest quality and strongest are boards made using wood chips, but there are manufacturers who use shredded furniture waste. Often this material is called liquid wood, as it consists of polymers and sawdust.

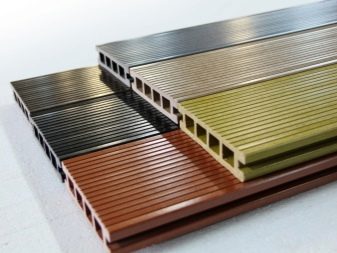

Such boards are produced in various shapes and sizes.

Production of wood-polymer composite meets high technical parameters, such as:

- high degree of wear;

- ease of processing;

- ease of installation.

With all this, it is a number of advantages that makes it stand out against other building materials.

These include the following:

- wear period is much higher than that of the wooden counterpart;

- as well as plastic, WPC deck boards will last more than a decade, even more than 20 years;

- wood composite boards have a lighter weight than wood products;

- due to the ease of processing the product from the duodenum can get the desired shape in the manufacturing process;

- special chemical impurities make this material heat- and moisture-resistant, not susceptible to rotting and the formation of fungi and mold;

- such boards are considered to be highly environmentally friendly and are considered harmless to both children and animals, and also have a non-slip surface;

- such a product has an aesthetic appearance, imitates wood;

- does not require purification.

In addition to the impressive list of advantages, it can be replenished with resistance to sunlight and the absence of a tendency to warp. Important is the property to retain its original color for many years. Therefore, boards made of wood-polymer composite will help to make the stairs different from others by a high degree of safety.

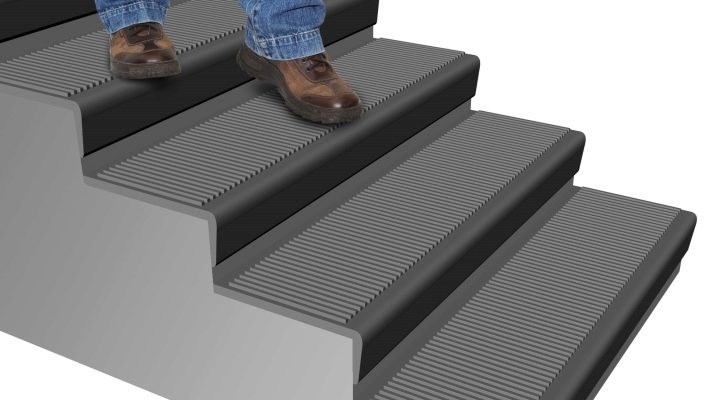

WPC steps - guarantee of reliability

Today, the building materials market provides a wide range of materials to install terrace steps or other types of stairs. Among the many win-win leader are the boards of the WPC.They are easy to install, and almost no need to take care of them, while they look beautiful and interesting for a long time.

By production this type of production can be modified in every possible way:

- make an external imitation of the board, made of wood;

- make copies of textures of various surfaces;

- use different water repellency methods.

A very important factor is the absence of a sliding surface. Due to the constituent element of polyvinyl chloride, such a material is ideal for all weather conditions, it does not matter whether it is heat or a forty-degree frost. In any case, such a product will definitely not be destroyed by the elements, even by fire, because it is also fire resistant. In the event of a possible fire, it will not ignite, but will only begin to melt, like plastic products. The main advantage is safety for human health. This material has been repeatedly tested for toxicity and can be safely considered to be highly ecological. Therefore, in addition to the external decoration of the territory, such material can be safely used indoors. Practicality in the care will please any owner, because for washing such a surface will be enough water and any cleaning substance, even with the addition of chemicals,as wood composite perfectly tolerates this kind of influence.

Board their WPC - ideal for terraces

If the buyer is concerned that over time, the steps of wood composite can be attacked by insects, then it is in vain. Manufacturers of WPC products have done everything to meet consumer requirements, so everyone can now make a quality staircase that has an attractive appearance that will adorn the design of the entire site. The main advantage of this product among the others is a high service life, because for buildings in the nature, this parameter is one of the most important.

Due to the peculiarities of the production technology of wood composite boards, they can repeat the natural pattern and texture of wood, making it an ideal substitute for wood planks. On sale there are special profiles that will help to hide the ends of the elements to make the stairs more aesthetic.

How to make the right choice?

There are two types of WPC boards, which differ in profile type:

- corpulent;

- hollow

The first ones have high impact strength, so experts advise using them when installing steps in the open air:

- on the terraces;

- on the piers;

- open-air cafeterias;

- on ships.

The second can be mounted on any platforms, another important factor is their low cost.

By type of mounting boards emit:

- suture;

- seamless.

They differ in the method of installation. To create a solid floor, seamless wood-composite products are used, which do not require special tools for attaching the boards to each other, unlike suture, where you need to leave a small gap between them - 2-4 mm.

Ready-made steps from the WPC can be purchased at any hardware store, or ordered online. If you have the desire and certain skills, you can make the steps of the WPC with your own hands. To do this, you need to purchase boards from wood composite of the desired colors, as well as familiarize yourself with the assembly process, which can be found in the form of a drawing on the Internet. But it is also necessary to remember that due to the unstable temperature and moisture the size of the boards may increase, for this you need to leave a small gap between them.

The modern construction market is represented by a large number of reliable manufacturers who have been delighting customers with high-quality products for years. The most popular are foreign suppliers, such as WAPS (South Korea), Novo-Tech GmbH (Germany), Silvadec (France), UPM (Finland) and others.

WPC steps make it possible not only to decorate the terrace or gazebo, but also to verify the quality of the products, thanks to the long service life while maintaining its original data. If wooden counterparts require careful maintenance, they are prone to the formation of mold and rot, and also do not tolerate temperature drops, then the analogue of the duodenum is very practical and does not require special care.

For the characteristics of non-slipping liquid wood steps, see the following video.