Proper laying of linoleum on concrete floor

During the final decoration of the room inevitably comes the moment of installation of a particular floor covering. But not each of them is easy and simple to lay on a concrete base on their own, but in the case of linoleum problems should arise.

Special features

Linoleum is a fairly durable flooring, made, as a rule, from polymeric materials.

This material, like any other has a number of pros and cons.

The advantages include:

- Easy installation. It is very easy to lay a covering on the prepared floor, the main thing is to lay it out beforehand and wait until the canvas is completely unfolded.

- Due to the features of its use is possible in almost any room.It is not afraid of humidity, temperature changes, and options with increased strength are not susceptible to dents.

- Linoleum does not require additional protective treatment, it is initially covered with a layer of gloss, which prevents mechanical damage.

Disadvantages are most often noted in the cheapest options.

The disadvantages include:

- When deciding to lay on the floor without a substrate, it is necessary to create a perfectly flat and smooth surface, which is not always possible in typical apartments.

- Cheap coatings may be overly resilient, which will result in the preservation of dents from furniture or other heavy objects.

- In addition, artificial coatings can produce an unpleasant chemical smell that is dangerous to the human respiratory tract.

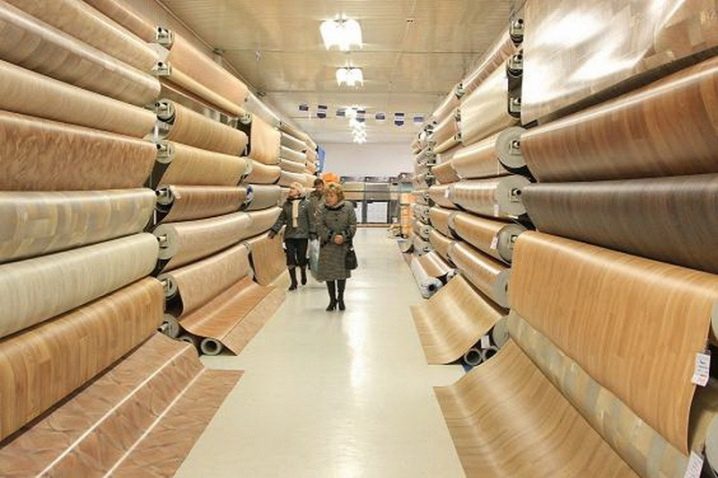

In the market, you can most often find two types of this type of coating: household and commercial.

Household linoleum is used in apartments and places where the permeability is not high enough. This option is able to provide sufficient heat and sound insulation for home use. In addition, household linoleum has a low cost, which allows it to cover large spaces without special costs.This coating offers a huge range of colors, as well as textures.

For rooms with greater traffic, as well as with sudden temperature changes, for example, on the balcony, it is better to choose a commercial type of linoleum. This coating has a longer service life, has excellent heat and sound insulation properties, and also has a wide range of colors and textures. You can pick up material with imitation of wood, wool and even masonry.

It is worth remembering that regardless of the class of wear resistance, you should definitely choose an option made from natural materials. Only such linoleum can not only last for a long time, but will not release harmful substances, evaporation from the surface of which is a frequent occurrence for non-natural materials.

First of all, it must be remembered that in order to avoid problems during installation, it is better to choose linoleum on a special substrate. Laying linoleum on a concrete floor with a substrate will be easier, but this is not the only plus of using additional material. Properly chosen substrate will help to increase the service life, give softness to the coating or, on the contrary, give hardness.Also, the substrate is able to provide additional sound and heat insulation in the room.

The most common materials for the substrate are:

- Styrofoam;

- Jute;

- Cork coating;

- Polyethylene foam;

- Composite.

The cheapest and most versatile material is, of course, foamed polyethylene. It extends the service life of the coating, and is also a versatile material that has been successfully used with other types of flooring.

By means of which, fixing the coating on the floor will directly depend on the desired period of use and the quality of the coating. If you plan to lay the floor in the apartment for a short time, it is better to use special fixing tape for fixing, but if the repair is not planned for a long time, then it is advisable to stop the choice on special glue or mastic.

Floor preparation

Laying linoleum at home consists of the following steps:

- Measurement of the premises and the calculation of the material.

- Floor preparation for installation.

- Cutting linoleum, its laying and fixing.

In order for it to serve long enough, retaining its original appearance,it is necessary to approach the second point with the greatest responsibility and to prepare the floor as thoroughly as possible, because due to the peculiarities of linoleum as a coating, every gap, scratch or other unevenness on the surface will become visible quickly enough.

Laying linoleum on a concrete floor requires the least effort with respect to other materials of the base of the floor. For example, to level a wooden floor will require several times more skills and materials.

So, in order to prepare a concrete floor, you must first clean its surface. It is necessary to take out all the furniture, remove the old coating, if it is, if it is removed, remove the old plinth, and also sweep away all the construction dust that is formed during dismantling, after that the floor should be slightly moistened with water.

The most common and easiest way to level the floor - this couplerwhich is a mixture of sand and cement. The required solution is obtained by mixing in a ratio of 1 to 3 cement and well-sifted river sand. The resulting mixture for leveling must be thoroughly mixed, and then applied to the floor, not forgetting to gently level it.For convenience and to achieve the most even surface, it is worth using special beacons - these are wooden or metal slats, which are installed on the floor at a distance of one and a half meters from each other. The filler fills the distance between the beacons, providing the same level of coverage. The thickness of the applied layer will directly depend on the initial relief.

Screed floor dictates some rules for the master. So, for example, during the drying of the solution, it is necessary to ensure its constant moistening, otherwise cracking of the coating may occur, which will require additional work or even its replacement. Usually for complete drying it is necessary from 5 days to a week. These manipulations will allow you to get a perfectly flat floor, on which you can lay linoleum immediately after a small grinding and cleaning of dust.

In addition, uneven concrete floor can save laying plywood or cork sheet. Such a substrate is able to provide a smooth coating with additional noise insulation. The time required for this alignment option is several times smaller, however, thanks to the installation of a wooden substrate, this method is better suited for wooden floors, since plywood is fastened to it with self-tapping screws,but for the concrete base will require the purchase of special glue.

If necessary and desired, you can combine two ways to level the floor. Immediately after complete drying of the cement screed, it is necessary to lay cork sheets, plywood or foamed polyethylene on the floor surface. These substrates will not only fix the leveling effect, but also provide additional thermal and sound insulation, as well as a better grip with linoleum.

How to put?

Before laying the linoleum, it is necessary to make careful measurements of the room, which will help determine the required size of the coating. In order to determine the size of the sheet of material, it is necessary to measure the length and width of the room, by multiplying these two dimensions, the area will be obtained, and it will help determine the required size of the linoleum canvas.

When buying a material, you need to focus on the area of the room, but do not forget to add to the measurement of 20-30 centimeters of stock. This will not incur large financial costs, but will allow not only not to miscalculate in case of measurement errors, but also to cut out the cover, if necessary, to lay it on the floor of a non-standard form.

After the necessary footage has been purchased, it is worthwhile to take care of the selection of some more tools that will be needed in the process of working with your own hands.

Installation is best done with the following kit:

- Good powerful vacuum cleaner. It is better if it is industrial, because it is easier to remove construction dust and unwanted garbage with its help.

- Laying linoleum is impossible without a sharp construction knife and scissors, with the help of which not only the floor material will be cut off, but also the litter that goes under it.

- If the installation will be made directly on the old screed, then you need to take care of the presence of a grinding machine or a sufficient amount of sandpaper. Before laying a new material, the old floor will need to be carefully sanded.

- Nastilka assumes also use of a long building ruler. With its help it is possible not only to measure the cut, but also to check the coverage for creases.

- In addition, you need a special glue and spatula to apply it.

- If you plan to lay several cuts with a seam, you should stock up with a mortar for sealing the seams, otherwise moisture and debris may get into them, which will ruin the entire coating.

So, when there are all the necessary materials, the floor is already leveled, if necessary, the chosen substrate has been laid, you can go directly to the flooring. The styling technology is simple. Begin with size adjustments. The material is laid out on the surface and with the help of scissors and a sharp knife it is cut, the holes for pipes, corners and other necessary functional elements are cut depending on the shape and type of the room. When trimming it is worth remembering that the canvas should be stretched as much as possible from one wall to another, otherwise creases and bubbles may form on the surface, which will look unaesthetic and shorten the service life.

After adjusting the dimensions of the canvas, you must fasten it to the concrete surface. There are three common mounting options. Oddly enough, the first type is the absence of fasteners as such. Linoleum is well stretched and secured only with the help of plinth. This option of flooring is advisable to use only in rooms with small dimensions.

The second common method is to mount on adhesive tape. This is a rather complicated and time-consuming method.First you need to stick the tape around the perimeter of the material, after which, gradually removing the film, you want to lay the canvas and smooth it on the floor.

The most expedient method of fastening for rooms with large cross and large dimensions is gluing to a special adhesive solution. To complete the process of flooring, it is necessary to fasten the material around the perimeter with the help of baseboards.

After laying in any way, it is necessary to give the coating a few days for drying and shrinkage, after which you can put any furniture on it and use the room for its intended purpose.

How to lay Lenoleum correctly, you can see in the next video.

What is better to fix?

In the previous paragraph, three ways of attaching linoleum were mentioned. This is an adhesive-free method, adhesive tape and glue.

The most appropriate solution is, of course, to glue the coating to the concrete. This will help avoid the bubbling, peeling of the material, in addition, this type of attachment will somewhat strengthen the material itself, add rigidity and strength to it.

If you choose an adhesive method of attachment, you must choose the type of glue.It must match not only the type of material, but also be combined with a primer, which will be applied to the concrete before laying.

Today on sale you can find two types of glue:

- Dispersive;

- Reactionary.

These two types of adhesive solutions have their own characteristics and are combined differently with different types of primers. The most appropriate choice in order to ensure proper and high-quality gluing at home is dispersion glue. It is based on water, can be successfully combined with a substrate of any material, and also contains in its composition a special substance that prevents the formation of mold under the coating.

The reaction type of glue acts through a special chemical reaction, which is derived from the interaction of glue and linoleum base. This connection has a high grip. It is better to fix linoleum on this type of glue in places with high traffic, as well as in rooms with large dimensions.

The average cost of a universal adhesive solution is 160 rubles per kilogram.

In addition to various types of glue, glue mastic is often used to join the concrete floor and the chosen material. It is made on the basis of bitumen.In addition, resin or rubber may be present in the composition of this mastic, which allows for perfect adhesion, and at the same time, even minor irregularities or scratches on the concrete can be evened out, which can remain even after the most careful leveling. A special requirement for this type of mortar is to use only plastic tools for applying and leveling the mixture, since the metal can enter into an undesirable reaction with bitumen.

The procedure of gluing with any of the selected materials is extremely simple, only changes in the sequence of application are possible. So, glue can be applied directly on the floor or substrate or on the coating material itself. After drawing it is necessary to level the put layer of glue. Further actions will depend on the type of clutch material selected. If you choose a dispersion or reaction adhesive, you can immediately proceed to gluing and smoothing floors. But in the case of bitumen mastic, before the sticker it will be necessary to wait 15-20 minutes until the applied mass is slightly grabbed. Such an exposure will provide a more reliable grip, and the process of gluing will be easier.

If it is necessary to glue the fabric into a flat joint, it is necessary to apply glue to the concrete, but to lay the coating itself overlap. A gap of 2-3 centimeters must necessarily remain with this method of gluing. After that, you need to take a sharp industrial knife and cut through both layers, then remove the excess and cover the junction with a special putty on a glue base, which will ensure a smooth and strong joint. In addition, it is the technique of laying in the joint that necessarily requires gluing the canvas to the floor, otherwise the coating will all the time be bristling and moving away.

How can I take off?

The process of removing the old coating must be approached very responsibly. Mistakes in dismantling may adversely affect the health of the master. Drilling, sanding and other manipulations with linoleum, which will lead to the rise in the air of harmful dust from the adhesive base or substrate, are unacceptable. The effect of such particles on humans is extremely pernicious, they can cause serious diseases up to oncology. For a person with a tendency to allergic reactions, dismantling the old coating is a direct path to an attack of suffocation.

It is necessary to think a few times whether it is worth removing this material yourself.This procedure is undesirable and should be carried out in the most exceptional cases, especially since the new coating can be laid directly on the linoleum, since it is a good heat and noise insulator and may well serve as a substrate.

If the old material is still necessary to remove, it is necessary to comply with certain rules. It is imperative to use respiratory protection - respirators. In addition, you can take care of eye protection by wearing special glasses and protecting hands with gloves.

Dismantling can be carried out only after all the furnishings have been removed from the room. After removal, it is better to tear off and replace the wallpaper, since particles of harmful dust can settle on them. All the dust formed must be cleaned with a vacuum cleaner, the use of a broom or a broom is completely excluded. In addition, an excellent option in this case would be a vacuum cleaner with a washing function - water will beat the dust and prevent it from rising into the air, thereby preventing it from entering the human respiratory tract.

It should also take care of the humidity in the room - it is necessary to spray the room with plain water to increase the humidity, which will also reduce the spread of harmful dust in the air.

Before dismantling, you must take care not only of yourself, but also of others, and find out information on the availability of specialized points for recycling material. All debris left after the procedure must be tightly packed and delivered to the disposal point.

At the beginning of dismantling, it is necessary to prepare a solution of water with detergent, then make cuts with a sharp knife through the entire canvas. They must pass clearly from wall to wall. You should not cut deep, enough cuts to half the thickness of the material.

Further, not forgetting to constantly moisten the floor with liquid and soapy water, with the help of a spatula it is necessary to tear off the top part of the matter layer by layer. In the course of this should remain the last felt layer, the dismantling of which has the greatest danger to humans. In order to separate the felt base from the floor, it is necessary to thoroughly soak it with soapy water, it must be damp. After saturating the entire layer, it is worth starting the moistening again, only now the whole segments will not be affected, but individual segments. This is necessary so that the layer does not have time to dry.Liberally moistening areas of the felt layer, you need to slowly and carefully begin to scrape it off the floor with a spatula. After removal, it is necessary to thoroughly vacuum and then clean the floors in the room.

For maximum safety and speed of dismantling, it is better to produce it in a pair, so one can quickly wet the layers, and remove the second one and immediately pack them in garbage bags, since long debris and movement on it are also undesirable and unsafe.

Following these rules, you can safely clean the room from the old coating, but today firms provide services for the professional dismantling of linoleum, which can be easily accessed if there is not enough confidence in their abilities. Specialists will quickly and safely remove the cover and provide the host with an already prepared field for further activities.

An alternative to dismantling may be laying a new canvas over the old one. This is the easiest and most convenient way to upgrade flooring.

Modern technology has made a big leap forward, and today you can easily restore damaged linoleum.With the help of special materials and polishing without removing it, you can get a refreshed floor that can last for quite a long time. If the replacement is planned due to the appearance of dents, then they can also be masked with a special mixture. On top of the linoleum, you can lay any substrate that will serve as the basis for a new floor. This method also avoids unsafe health dismantling.

Successful examples in the interior

Despite the insecurity of the material in the dismantling, as well as the emergence of many alternatives, linoleum does not lose its popularity and sometimes its use in the interior is quite successful and expedient. The examples below illustrate this.