Tarkett commercial and semi-commercial linoleum: what is it?

Tarkett linoleum is the most recognizable and popular product on the world market of finishing materials. The history of the eponymous company began more than 130 years ago with the production of floor coverings, known not only in Sweden, but also far beyond its borders.

Today Tarkett concern is the largest manufacturer, having enterprises in many countries of the world and producing excellent products.

Benefits

Relying on the age-old experience, applying the latest scientific developments and using high-tech equipment, the enterprises of the concern set up the production of high-quality floor coverings endowed with the following advantages:

- Absolute environmental safety. By production of linoleum the harmless materials which have the international certificates of conformity and answer all sanitary and hygienic standards are used. The presence of formaldehyde resins in products is ten times lower than the average for most similar products. The coatings completely lack DOP plasticizer, which has a negative effect on health and well-being and is often used by other manufacturers.

All models comply with the standards of GOST of Russia, which distinguishes Tarkett linoleum from other products made according to the Technical Conditions (TU).

- competent logistics and a well-thought-out pricing policy make it possible to manufacture products in a wide price range. This ensures high demand and greater popularity of coatings;

- strength, resistance to mechanical stress and temperature, moisture resistance and excellent sound insulation properties indicate the high quality of linoleum and its durability;

- A large model range with a huge variety of colors and designs allows you to choose a coating for any interior.

Semi-commercial

Products whose thickness ranges from 2 to 3 mm, and the weight of one square meter is 2.5 kg is called semi-commercial. It is believed that this type of coating is an improved version of household linoleum, which is slightly less than industrial properties. Products correspond to 31-34 class of wear resistance that allows to use them in rooms with average passability: in living rooms and offices.

Linoleum consists of a bottom layer made of foamed PVC and reinforced with fiberglass and an outer protective layer imitating the pattern of wood fibers, stone and marble. The coating is produced in a comfortable width of from two to four meters, which makes it possible to use it rationally in rooms of different size with the minimum number of scraps.

In the manufacture of some models used antibacterial additives that allows you to use the coating in medical and orphanages. Also, the products are not prone to the accumulation of static electricity and are fairly simple to maintain, but alkalis and acids should not be used in the processing of semi-commercial linoleum.

In order for linoleum to serve for a long time and not lose its operational properties, once a year it is necessary to impregnate it with a special compound.

Commercial

Industrial coating has a thickness of 3.5 mm and is characterized by the highest level of wear resistance and strength. A protective layer of 0.7 mm reliably prevents damage and abrasion due to heavy loads. The weight of a square meter of the product varies from 2.9 to 5 kg.

Linoleum is produced in a universal width of 2 to 4 meters. The scope of application of commercial coverage is quite wide and covers a huge number of public spaces, production halls and industrial enterprises.

Industrial linoleum is of two types: heterogeneous and homogeneous.

Heterogeneous

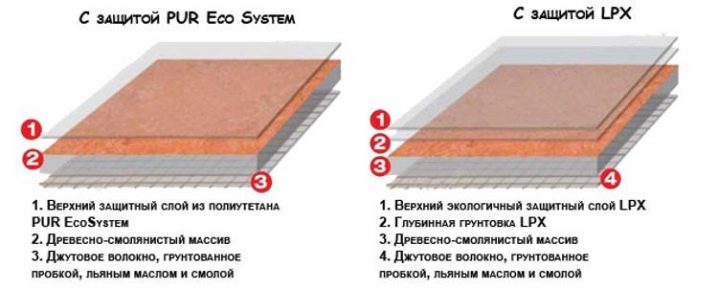

Heterogeneous consists of various layers of the texture: the bottom, made of PVC, the middle one has a decorative pattern and an external polyurethane layer 0.8 mm thick, which ensures the protection and durability of linoleum. Stone chips and metal dust are used to enhance the strength of a heterogeneous web. The surface copes well with large pedestrian loads, and the wheels of chairs, furniture legs and sharp heels do not leave dents and prints on it.

The drawing is maintained throughout the entire life cycle, does not fade and is not trampled.

Homogeneous

Homogeneous appearance - the standard of strength and durability of flooring. The canvas is completely homogeneous - there are no layers in it, and the drawing is applied by hot pressing directly onto the base. This structure allows you to repeatedly restore coverage, which makes it an indispensable option when used in schools, clinics, shopping centers and shops with heavy equipment and high mechanical stress on the floor.

The cost of products starts from a thousand rubles per meter and can reach 3-5 thousand, depending on the model and width.

For production premises, webs are used in the manufacture of which graphite powder and additives with carbon particles are used. Due to this composition, the coating neutralizes static electricity and can be used in workshops with high-frequency electrical appliances.

In rooms with high humidity, commercial homogeneous linoleum is also an ideal coating. The surface is resistant to ultraviolet rays and, unlike semi-commercial coating, it tolerates processing by any means of household chemicals.

Industrial linoleum is resistant to any aggressive environmental influences and can be used in the temperature range from -40 to +50 degrees. For durability and durability, it can be compared with a coating of marble and tile. The manufacturer guarantees impeccable service coverage for 15-30 years depending on the model and operating conditions.

All models of commercial linoleum are flame retardant and do not sustain combustion.

Selection rules

Each model of semi-commercial and industrial types of linoleum have different wear resistance. This type of classification is displayed in product labeling consisting of two numbers and giving a complete picture of the model. The first number indicates the type of space in which this coating is recommended. Household is indicated by the number 2, office - 3, and production - 4. The second number indicates the degree of the expected load.

Both indicators have a range from one to four and can be replaced with graphic images in the form of houses and schematic images of people, depending on the wishes of the manufacturer. For example, grade 43 wear resistance indicatesthat linoleum is intended for installation in a production area with high flow intensity or a strong mechanical effect on the floor.

Next, you should pay attention to the overall thickness of the product, given that the thicker the linoleum, the better the cushioning and the higher the sound and thermal insulation properties of the coating. You also need to specify the thickness of the protective layer. From this will depend on the resistance of the pattern in heterogeneous models and the general appearance of the surface.

Several types of materials are used as a protective film. For example, Extreme Protection increases the strength of the upper layer seven times, Titan creates a lacquer surface, and the embossed Turex coating very accurately emits the wood pattern and texture of the stone.

Then you should determine the width of the coating, taking into account the area of the room. This will allow more efficient use of material, to achieve the least number of joints and trimming. The length of the rolls is 20-30 meters, and the width varies from 2 to 5. When choosing linoleum in a wet room, you need to choose products with a marking index E. The higher the number after the letter, the more moisture-resistant the model.

If the flooring will be used on heated floors, the products must have the inscription "warm floor". The lightness level is indicated by the EN 20105-B02 index, where the last digit indicates the number of points in the range from one to eight.

Abrasion is indicated as a single letter and has the following indicators: T is a very durable PVC coating with very low abrasion, P is average, M is high, F is the highest. Allowable changes in linear parameters are also marked. This indicator should not exceed 0.4%.

Reviews

Commercial and semi-commercial types of Tarkett linoleum have a lot of positive reviews. There is a long service life and high performance coatings, a wide variety of colors and textures, as well as a wide price range.

Among the drawbacks, attention is drawn to the persistent smell of semi-commercial type products and glue. There were also cases of pink spots on the floor with the impossibility of their removal. In inexpensive models there is a slight deformation of the coating from the legs of the furniture and the wheels of the seats.

You will learn more about Tarkett commercial and semi-commercial linoleum from the following video.