Substrate under linoleum on a wooden floor

Substrates under linoleum are widely represented on the market of building and finishing materials. A wide range of products that differ in purpose, cost and origin easily allows you to choose a substrate for wooden floors.

Purpose

For some, for example, self-leveling floors, the use of substrates is not required. They are fairly smooth and do not require additional surface correction. In rooms equipped with wooden floors, the use of substrates is necessary for the following purposes:

- To provide increased sound and heat insulation. This is especially true for residents of the first floors in the case of an unheated basement, as well as for people living above noisy rooms: fitness centers, private kindergartens and entertainment facilities.Wood, as a material, is a good sound insulator, but in combination with the substrate and linoleum, this effect will be enhanced several times.

- To level the floor. If you put the coating immediately on an uneven surface, then over time there will be creases, irregularities and cracks on the linoleum. Therefore, it is more rational to spend one time on the substrate than to constantly change the flooring.

- To increase the depreciation properties of linoleum. This is especially true when using a single-layer coating that does not have a fibrous base. Walking on the soft floor is much more comfortable than on a hard and hard surface.

Kinds

According to the material for the manufacture of the substrate under the linoleum are artificial and natural origin. Each species has distinctive features and a number of advantages. This allows you to accurately select the material, taking into account the future operating conditions of the flooring:

Jute backing

The substrate of jute is made from environmentally friendly plant materials. The fibers are impregnated with fire retardant, which makes them not susceptible to rotting and fire. The material perfectly absorbs the excess moisture, while remaining dry, and gradually removes it.The use of jute substrate is justified in wet areas without the risk of damage to the fibers and linoleum. In the manufacture of products used needle-punched method, followed by thermal rolling on the mill.

Thanks to this technology, the material becomes elastic and able to quickly restore its original shape after exposure to heavy objects. This property of the substrate eliminates the deformation of linoleum and significantly prolongs its service life. The only drawback of the jute substrate is its low sound insulating ability.

Linen underlay

The flax substrate is also a natural material, and has excellent ventilation properties. Due to this, there is no risk of mold and mildew, and to prevent the appearance of bugs and insects, the material undergoes flame retardant treatment. The flax substrate does not accumulate moisture and is produced using the same technology as the jute models.

The disadvantage of this product is low noise absorption and low thermal insulation. Despite these shortcomings, the flax substrate is well suited for single-layer linoleum due to the factthat when laying on a wooden floor does not require high rates of these qualities. This is due to the fact that the wooden floor is quite warm and well retains sound.

Cork backing

The cork substrate is also a completely natural, environmentally friendly material. It is made of crushed oak bark. Due to its structure, it has high depreciation, sound and thermal insulation properties. The substrate is quite soft, so for rooms where you plan to install heavy furniture or mechanical impact on the floor, this option is not suitable.

Do not use this type of underlay to level the floor.having height differences and cracks. When operating in such conditions, the material will wrinkle, as a result, linoleum will also begin to deform, repeating the defects of the floor. In some models, cork is used in combination with rubber. Such products have sufficient rigidity and can be used in specific conditions of large loads and surface irregularities. The disadvantages of cork substrate is the high cost and low strength of the material.

Felt backing

The felt underlay will give the floor softness, perfectly warm and perfectly soundproof the room. It is used for children's rooms and bedrooms.

Combined version

Flax, wool and jute are used in its manufacture. This model has excellent thermal insulation and noise absorbing properties, has a long service life and repels moisture. From minuses high cost of products is marked.

Plywood, chipboard and OSB panels

Using these materials, you can perfectly level the surface of the floor, which significantly extend the life of linoleum. The disadvantage is the intolerance of moisture, under the influence of which the substrate becomes unusable.

Artificial synthetic substrates

Artificial synthetic substrates are represented by foamed material and porous polymers. Such models are made on the basis of isolon and penoizol, which are not absolutely pure raw materials, from an environmental point of view. The material has low thermal and sound insulation properties and is easily deformed. This option can be put under linoleum in low-traffic areas.

Installation rules

For proper laying of the substrate and further comfortable operation of the floor covering, it is necessary to observe certain conditions:

- The day before the work begins, you need to roll out the material and let it rest. The air temperature in the room should be at least 16 degrees. Then the floors are thoroughly promet. It is also required to eliminate wide gaps, chips and other defects that violate the integrity of the floor. This can be done with the help of special polymer compositions. The use of cement in such cases is unacceptable due to some mobility of the wooden floor and the risk of chipping of the composition.

- After preparing the floor is required to proceed to the layout of the substrate. The strips of material are glued to each other in width with adhesive tape. This technology is used for linen, jute and felt substrates.

- Cork cloth is forbidden to stick to the floor due to the possibility of deformation, which can occur due to different thermal expansion of the adhesive and the substrate. Soft substrates must be cut near the walls so that the gap is within 3-5 mm. Then you can proceed to the layout of linoleum.

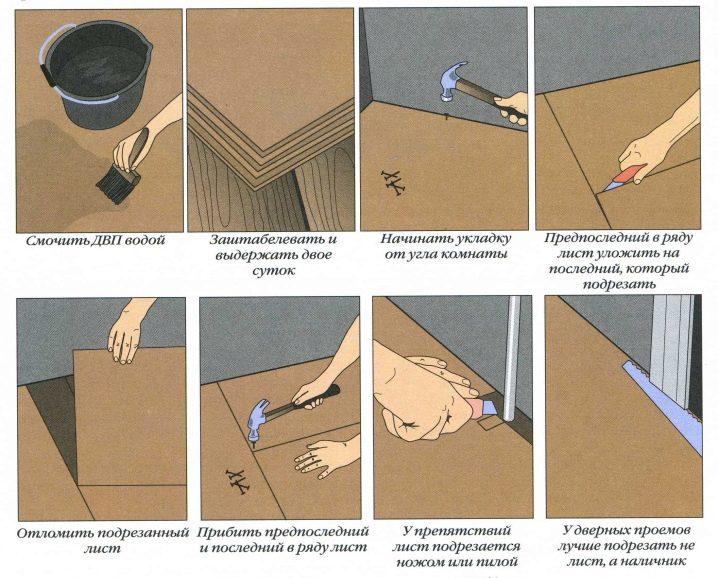

- If sheet material is used as a substrate, then it is necessary to prepare the surface as follows: level the floor using a planer or a grinder, beat shaky floorboards and fill up large gaps with a polymer composition. When using GVL installation is carried out in two layers with perpendicular laying of sheets relative to each other. In the case of plywood, it is necessary to ensure that the joints between the sheets do not coincide with the joints of the floorboards.

- It is recommended to use self-tapping screws of medium length, the fastening step should be 30 cm when installing GVL and 15 for mounting plywood. The distance between adjacent sheets should be from 5 to 10 mm. Otherwise, when the material expands, the surface will bulge and swell, which can lead to creases and even rupture of linoleum.

- In case of pronounced unevenness of the floor surface, the use of two types of substrate is recommended. Successful is the combination of plywood sheet and any soft roll material. It would be rational to use the budget option itself. Before laying, it is necessary to prepare the floor by cleaning it from dirt and eliminating serious integrity defects.

- Next, you need to lay a soft substrate overlap the wall and glue the butt-laid canvases between them. Plywood sheets are laid and screwed on top, and only after that are the excess soft substrate cut off. The use of a double substrate allows you to achieve a perfectly flat floor surface, provides excellent sound and heat insulation, and significantly prolongs the life of linoleum.

- In some cases, old linoleum can be used as a substrate. This is acceptable in the absence of damage to the old coating in order to avoid the repetition of defects, crevices and creases on the new one. And to ensure a more comfortable operation, it is possible to mount the substrate under linoleum, which already has a warm base in the form of a lower layer. In such cases, it is possible to achieve high thermal insulation and shock absorption.

Reviews

Consumers appreciate the performance properties of substrates, noting their diversity and wide price range. Attention is paid to their ability to significantly extend the life of linoleum and to warm the floor well. Among the shortcomings are the additional labor costs during installation and the high cost of some models.

Learn more about how to choose the substrate for linoleum on a wooden floor, you will learn from the following video.